EB-cured textile sizing agent and preparation method and application thereof

A technology for textile sizing and curing resin, which is applied in textile and paper making, abrasion-resistant fibers, fiber types, etc., and can solve the problems such as no public reports on yarn sizing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

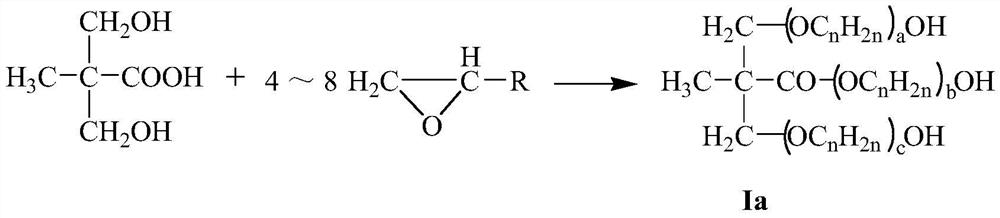

[0071] In the 6L autoclave, drop into 1340 grams of 2,2-dimethylol propionic acid (C 5 h 10 o 4 , molecular weight 134), 40 gram sodium formate, be warming up to 155 ℃, start to drop 2200 gram oxirane (C 2 h 4 O, molecular weight 44) to react, temperature control 155 ℃ ~ 165 ℃, pressure 0.10 ~ 0.40MPa, dropwise for 3 ~ 4 hours, after dropping, 155 ℃ ~ 165 ℃ for 2 ~ 3 hours, then cooled to below 80 ℃, Discharging gets crude product; Crude product adds 40 gram activated clays and stirs for 30 minutes, obtains 3469.2 grams of clear and transparent trihydroxy polyether esters (C 15 h 30 o 9 , molecular weight 354), the structure is shown in the following formula, wherein: n=2, a+b+c=5.

[0072] R=H.

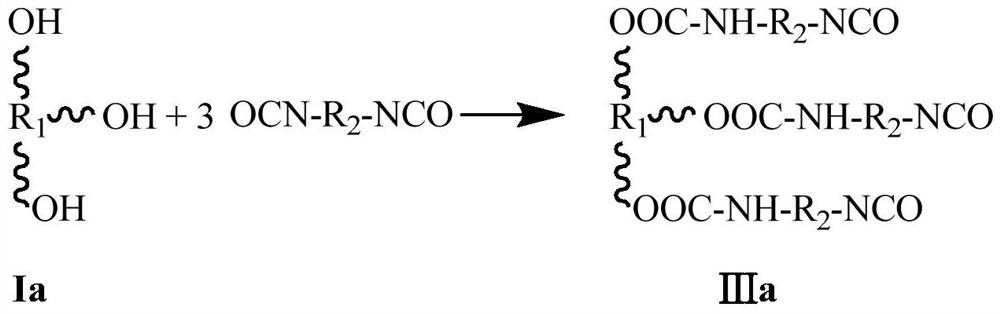

[0073] In the 3000mL four-necked flask, drop into 177 grams of trihydroxy polyether ester (C 15 h 30 o 9 , molecular weight 354), 333 grams (1.5mol) IPDI, 0.2 gram catalyst dibutyltin dilaurate, be warming up to 60 ℃~65 ℃ and stir insulation reaction 2~3 hours, then add 1...

Embodiment 2

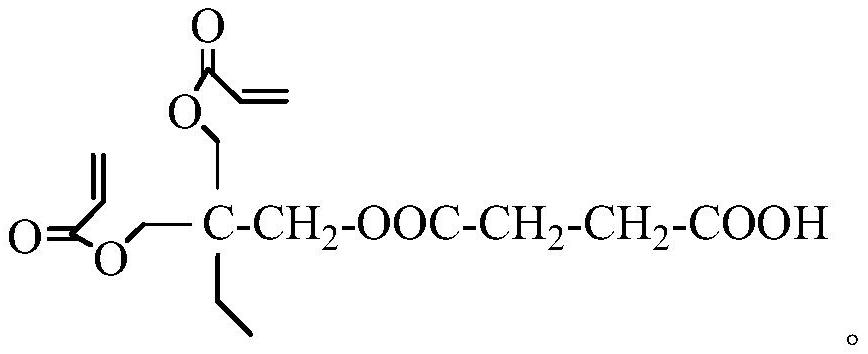

[0081] 1000 grams of succinic anhydride, 15 grams of benzyltriethylammonium chloride, 1.5 grams of p-hydroxyanisole, and 3457 grams of trimethylolpropane diacrylate (molecular formula: C 12 h 18 o 5 , molecular weight 242, diester content by 70%), start stirring, heat up to 70°C, keep warm for 1 hour, then heat up to 80°C for 1 hour, then heat up to 100°C for 3 hours, react until the acid value is constant, and then After cooling to below 50°C, a bifunctional acrylate with a carboxyl group having the structure shown in formula IV is obtained.

[0082]

Embodiment 3

[0084] In the 3000L reactor, drop into 80 kilograms of toluene, 500 kilograms of cyclohexane, propoxylated trimethylolpropane (C 15 h 32 o 6, molecular weight 308) 720 kilograms, 564 kilograms of acrylic acid, 7 kilograms of hydroxyanisole, 4.6 kilograms of hypophosphorous acid, 34.8 kilograms of methanesulfonic acid; Stirring is started, and compressed air is continuously introduced into the kettle through the distributor at the bottom of the kettle, and the temperature is raised to 80~ Start reflux dehydration at 86°C, esterification reaction for 10-12 hours, kettle temperature 88-92°C, when the reflux dehydration until no water comes out, the acid value is 30-35mgKOH / g, the reaction is over, cool to room temperature; add 38.2 kg Caustic soda and 95.5 kg of water, stirred for 30 minutes; 11.5 kg of magnesium polysilicate was added, stirred and adsorbed for 30 minutes; then the water and solvent were distilled under reduced pressure at 50-95 ° C under a vacuum degree of -0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com