Water keeping gel and its method for producing

A technology of water-retaining gel and gel, which is applied in the field of superabsorbent resin, can solve the problems of poor and small water-retaining capacity, can only absorb several times or even dozens of times of its own mass, and dehydration, etc., to achieve production costs Low cost, easy to operate, and convenient for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

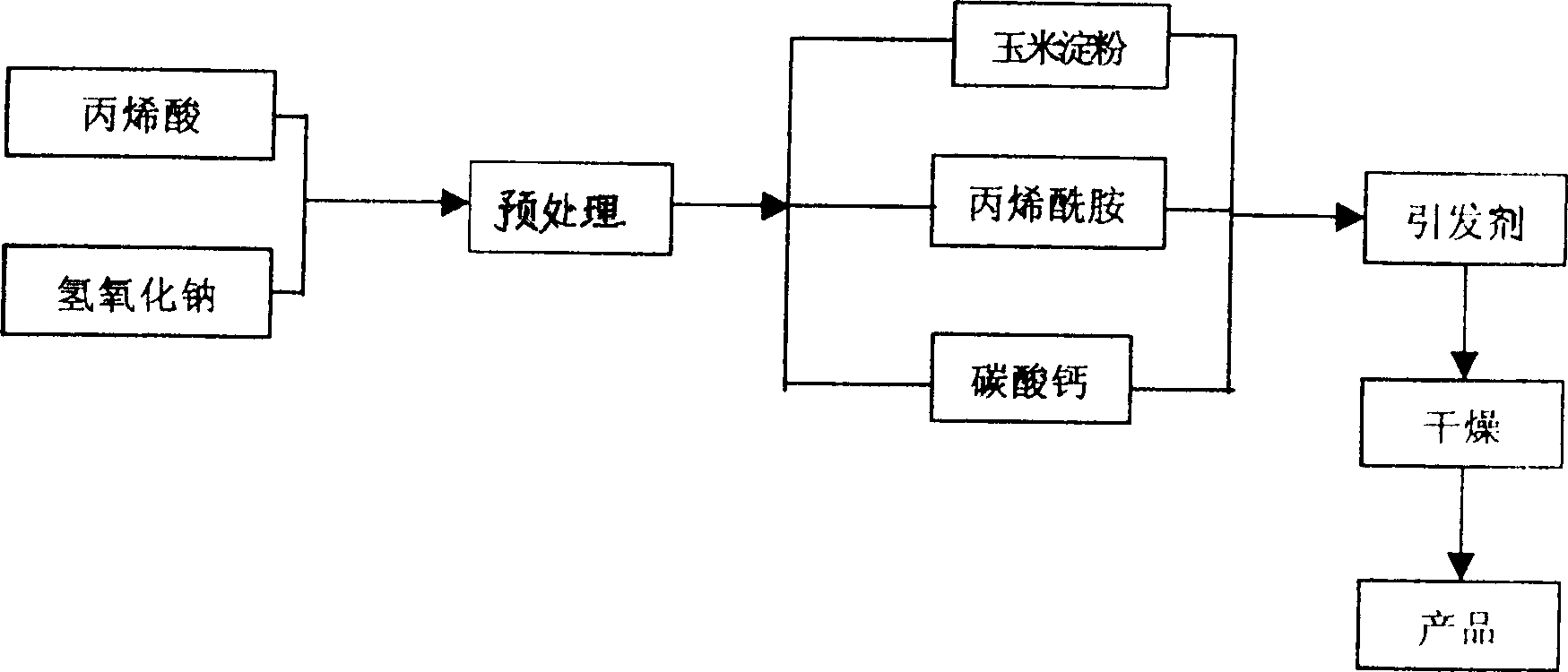

[0009] The process flow provided by the invention is shown in the accompanying drawings: first dissolve sodium hydroxide in a certain amount of water, then add a certain amount of acrylic acid for pretreatment. Then add cornstarch, acrylamide and calcium carbonate in sequence, stir evenly, and maintain the temperature of the reaction solution at about 50--52°C. Finally, an initiator (such as ammonium persulfate, etc.) is added to carry out graft polymerization, and the holding time is 1.8--3 hours. After the graft polymerization reaction is completed, the reaction liquid can be poured into a special mold, put into a constant temperature dryer at 100°C for drying, and the water-retaining gel product can be obtained.

[0010] The gel prepared according to the above method, its components and weight percentages are shown in the attached table, namely: corn starch 4.5-4.7, acrylic acid 21.4-22.5, acrylamide 9-9.5, ammonium persulfate 3.2-4.5 , calcium carbonate 4.5--4.7, sodium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com