Bionic cooling fabric

A cooling fabric and bionic technology, applied in the field of clothing fabrics, can solve the problems of local supercooling stimulation, short cooling time, bulky volume, etc., and achieve the effect of keeping cool and comfortable, long cooling time, and increasing evaporation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

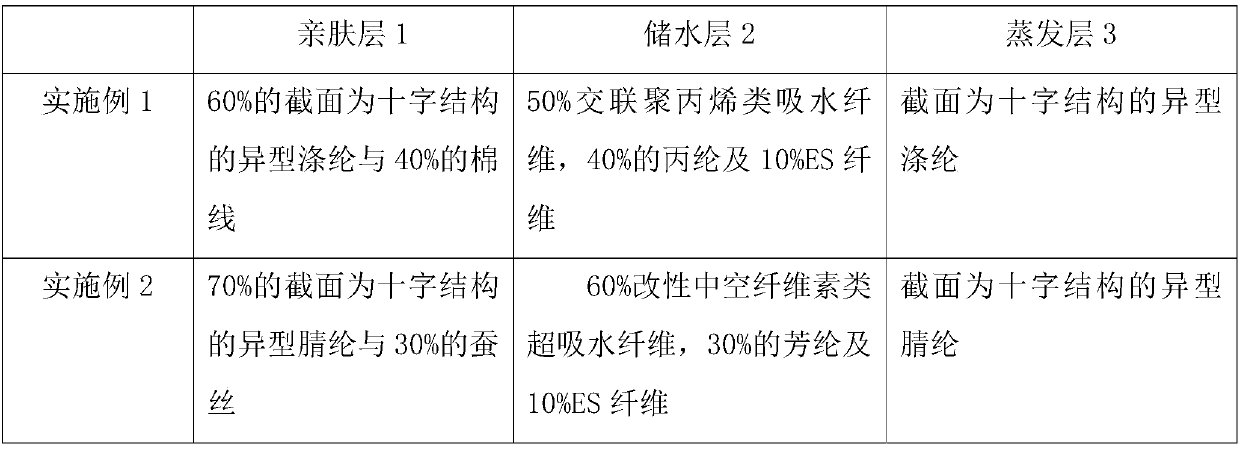

[0027] Such as figure 1 As shown, the bionic cooling fabric is provided with a skin-friendly layer 1, a water storage layer 2 and an evaporation layer 3 in sequence; the skin-friendly layer 1 is a fabric made of 60% cross-section shaped polyester and 40% cotton thread, and the surface density is 200gsm; the water storage layer 2 is a non-woven fabric made by blending 50% cross-linked polypropylene water-absorbing fiber, 40% polypropylene fiber and 10% ES fiber with a needle punching process, and the surface density is 400gsm; the evaporation layer 3 is a cross-section of Porous fabric made of special-shaped polyester with cross structure, with an area density of 150gsm.

Embodiment 2

[0029] Such as figure 1 As shown, the bionic cooling fabric is provided with a skin-friendly layer 1, a water storage layer 2 and an evaporation layer 3 in sequence; the skin-friendly layer 1 is a fabric made of 70% cross-sectional shaped acrylic fiber and 30% silk, and the surface density is 300gsm; the water storage layer 2 is a non-woven fabric made by blending 60% modified hollow cellulose superabsorbent fiber, 30% aramid fiber and 10% ES fiber with a needle punching process, and the surface density is 200gsm; the evaporation layer 3 It is a porous fabric made of special-shaped nylon with a cross-section, and its surface density is 250gsm.

Embodiment 3

[0031] Such as figure 1 As shown, the bionic cooling fabric is provided with a skin-friendly layer 1, a water storage layer 2 and an evaporation layer 3 in sequence; the skin-friendly layer 1 is a fabric made of 50% cross-section shaped nylon and 50% cotton thread, and the surface density is 250gsm; the water storage layer 2 is a non-woven fabric made by blending 70% polycarboxylate superabsorbent fiber, 15% polypropylene fiber and 15% ES fiber with a needle punching process, and the surface density is 800gsm; the evaporation layer 3 is a cross-section of Porous fabric made of special-shaped nylon with cross structure, with an area density of 250gsm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com