Composite dressing for wound repair and preparation method thereof

A technology of wound repair and cellulose acetate film, which is applied in the manufacture of rayon, artificial filament made of cellulose derivatives, and fiber chemical characteristics, can solve the problems of inability to promote wound healing, long application time, and wound adhesion, etc. problem, to achieve excellent long-term antibacterial effect, inhibit the production of blood vessels, and promote the effect of angiogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

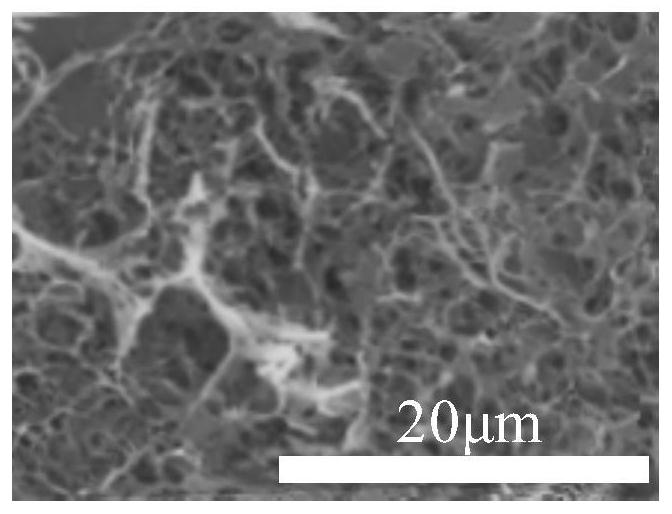

Image

Examples

Embodiment 1

[0032] Preparation of cellulose acetate membrane loaded with hyperoside:

[0033] Using the acetone / DMAC system with a volume ratio of 7:3 as a solvent, prepare a cellulose acetate spinning solution with a mass fraction of 11%, add hyperin at a concentration of 16 mg / mL, stir rapidly at room temperature until it is completely dissolved, and obtain an electrostatic Spinning the mother liquor, injecting the electrospinning mother liquor into an electrospinning machine for electrospinning to obtain a cellulose acetate film loaded with hyperin. Spinning process parameter settings: voltage 15KV, injection rate 0.5mL / h, receiving distance 17cm.

[0034] Preparation of composite dressings for wound repair:

[0035] Preparation of regenerated fiber silk membrane: The cellulose acetate membrane loaded with hyperin obtained above was laminated with upper and lower layers of polytetrafluoroethylene sheets, heat treated at 208°C for 1h, and then heated in 0.05mol / L NaOH-water / ethanol ( ...

Embodiment 2

[0038] The difference between the preparation of the hyperin-loaded cellulose acetate membrane and Example 1 lies in that: the mass fraction of cellulose acetate in the electrospinning mother liquor is 13%; the concentration of hyperin is 10 mg / mL.

[0039] The difference in the preparation example 1 of the composite dressing for wound repair is that the concentration of the aqueous collagen solution is 0.08 g / mL.

Embodiment 3

[0041] The difference between the preparation of hyperin-loaded cellulose acetate membrane and Example 1 lies in that: the mass fraction of cellulose acetate in the electrospinning mother liquor is 12%; the concentration of hyperin is 13 mg / mL.

[0042]The difference in the preparation example 1 of the composite dressing for wound repair is that the concentration of the aqueous collagen solution is 0.07 g / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com