A kind of nitrile rubber composition and preparation method

A technology of nitrile-butadiene rubber and a composition, applied in the rubber field, can solve the problems of easy extraction of nitrile-butadiene rubber plasticizer, poor durability, harm to human health and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

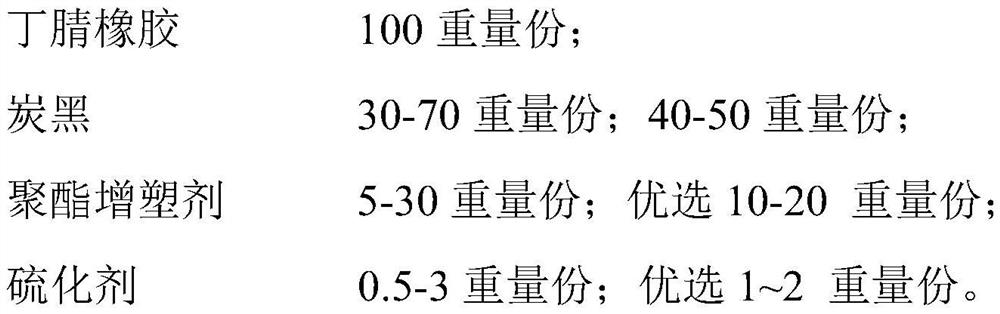

Method used

Image

Examples

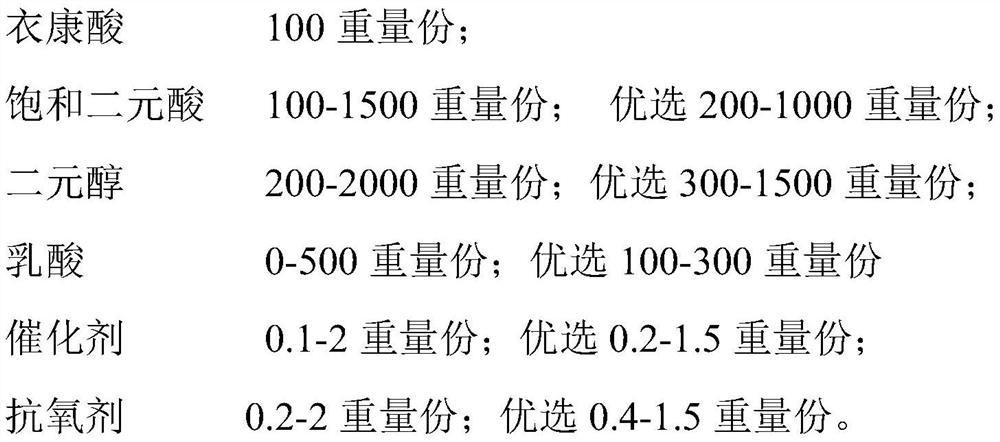

Embodiment 1

[0039] 350g of sebacic acid (SeA), 150g of lactic acid (LA), 300g of succinic acid (SuA), 100g of itaconic acid (IA), 483g of 2,3-butanediol (2,3-BDO), 333g of 1,4-butane Diol (1,4-BDO), 0.17 g of phosphorous acid and 0.67 g of hydroquinone were added to a four-necked flask, nitrogen was introduced, and esterified at 170°C under normal pressure for 4 hours, and then a catalyst, tetrabutyl titanate, was added. 0.83g, heat up to 180°C, remove small molecules in a vacuum state for 1h, cool to room temperature, and obtain a double bond-containing reactive polyester catalyst. Its molecular weight is 1110, and the double bond content in the unit molecule of the prepared reactive polyester catalyst is 0.66. The sources of raw materials are all commercially available.

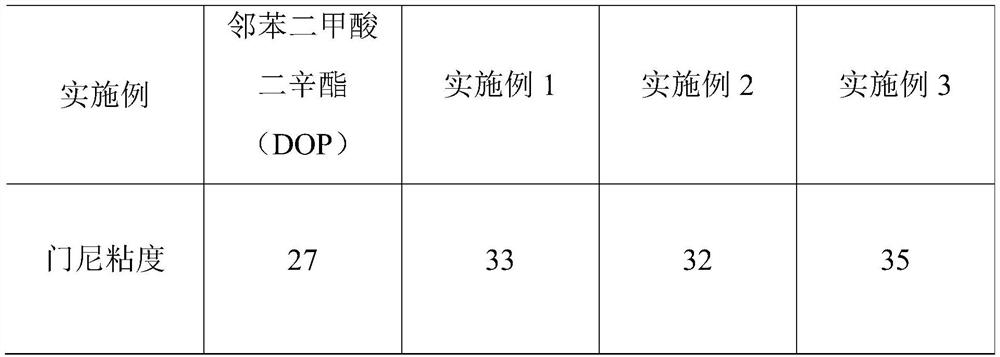

[0040] 100 parts of nitrile rubber (N230), 50 parts of carbon black (N330), 20 parts of polyester plasticizer, and 1.5 parts of vulcanizing agent DCP were sequentially added to an open mill for blending. The Mooney v...

Embodiment 2

[0042]67g sebacic acid (SeA), 150g succinic acid (SuA), 100g itaconic acid (IA), 315g 2,3-butanediol (2,3-BDO), 170g 1,3-propanediol (1,3- PDO), 300g lactic acid (LA) trimethyl phosphate 0.9g and hydroquinone 0.10g were added to the four-necked flask, passed nitrogen, and esterified at 160 ° C under normal pressure for 3 hours, then added catalyst tetrabutyl titanate 0.83g, heat up to 210°C, remove small molecules in a vacuum state for 4h, cool to room temperature to obtain a reactive polyester catalyst with a molecular weight of 1774 and containing double bonds. The double bond content in the unit molecule of the prepared reactive polyester catalyst was 1.09.

[0043] 100 parts of nitrile rubber (N230), 50 parts of carbon black (N330), 20 parts of polyester plasticizer, and 1.5 parts of vulcanizing agent DCP were sequentially added to an open mill for blending. The Mooney viscosity was measured, and the tensile properties were measured by the international standard ISO / DIS 3...

Embodiment 3

[0045] 483g of sebacic acid (SeA), 300g of succinic acid (SuA), 100g of itaconic acid (IA), 483g of 2,3-butanediol (2,3-BDO), 333g of 1,4-butanediol (1, 4-BDO), 0.80 g of trimethyl phosphate and 0.20 g of hydroquinone were added to the four-necked flask, nitrogen was introduced, and esterified at 150 ° C under normal pressure for 2 hours, then 1.5 g of antimony acetate catalyst was added, and the temperature was raised to 230 ℃, remove small molecules in a vacuum state for 6h, and cool to room temperature to obtain a reactive polyester catalyst with a molecular weight of 2909 and containing double bonds. The double bond content in the unit molecule of the prepared reactive polyester catalyst was 1.72.

[0046] 100 parts of nitrile rubber (N230), 50 parts of carbon black (N330), 20 parts of polyester plasticizer, and 1.5 parts of vulcanizing agent DCP were sequentially added to an open mill for blending. The Mooney viscosity was measured, and the tensile properties were measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com