Acrylonitrile butadiene and polypropylene thermoplastic crosslinked rubber

A thermoplastic vulcanizate and nitrile rubber technology, which is applied in the field of nitrile rubber and polypropylene blended thermoplastic vulcanizates, can solve the problems that have not yet been seen, and achieve the inversion of the phase state and the particle size of the dispersed phase. Control, excellent high temperature resistance, small effect of volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

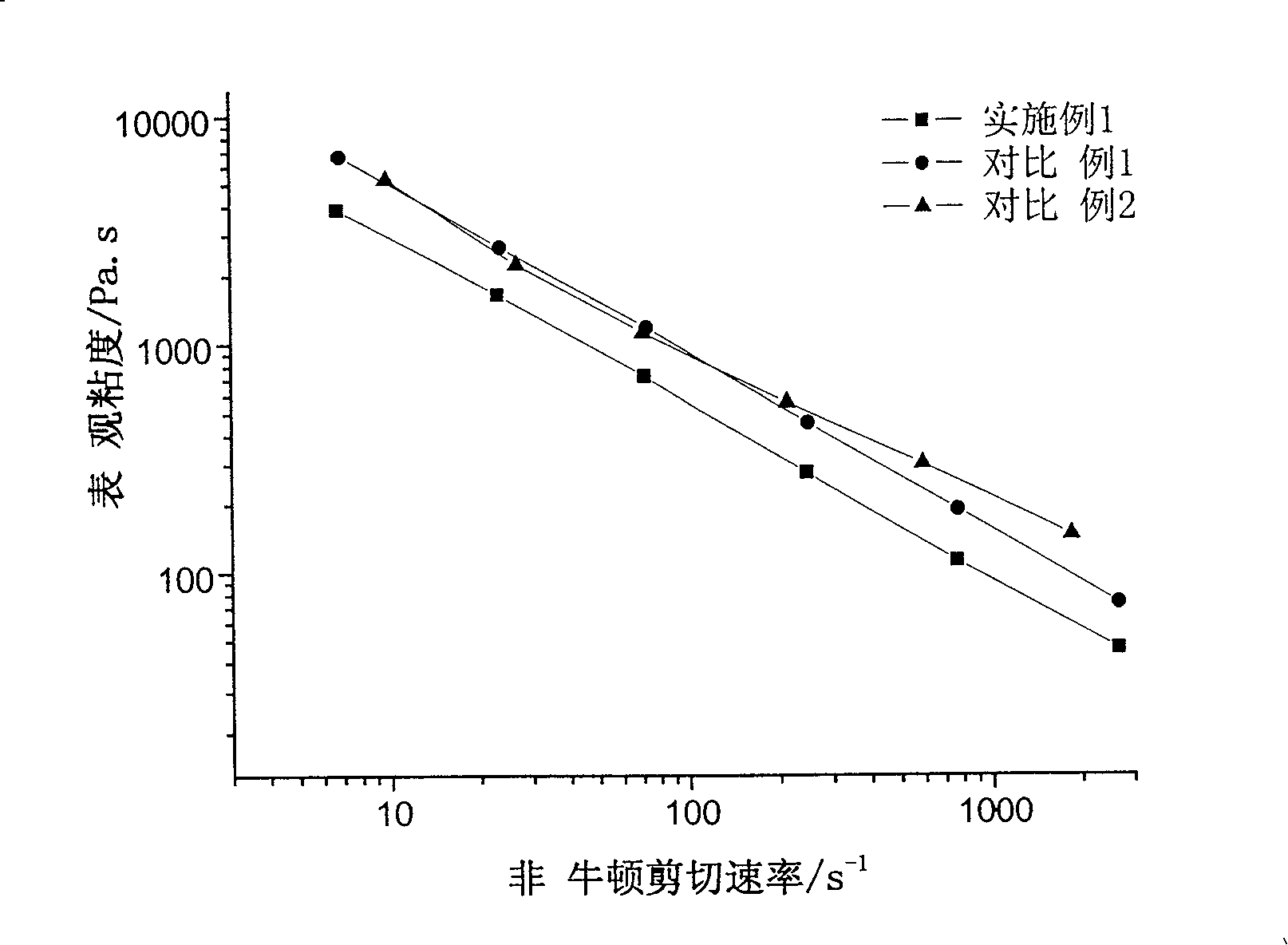

[0031] A 70 / 30 NBR-PP blend thermoplastic vulcanizate was prepared. Wherein, the content of nitrile rubber combined with acrylonitrile is 41% (mass percentage), and the Mooney viscosity is (ML1+4(100°C))59. Polypropylene is homopolypropylene with an isotacticity of 98%. The dosage of main plasticizer TOTM is 40 parts. The operation steps are as follows:

[0032] 70g nitrile rubber, 2g anti-aging agent RD and 5g compatibilizer B-terminal amine-based liquid nitrile rubber are mixed uniformly on a normal temperature open mill, and then it is grafted with 30g polypropylene, 10g compatibilizer A maleic anhydride Propylene and 0.3 g of antioxidant 1010 were put into a 180° C. double-roll mill and mixed evenly. After 5 minutes, add 9g vulcanizing agent t-octyl phenolic resin and 40g main plasticizer TOTM, and finally add 1.8g accelerator stannous chloride for dynamic vulcanization for 10 minutes. Compress and form on a flat vulcanizer to obtain a blended thermoplastic vulcanizate...

Embodiment 2

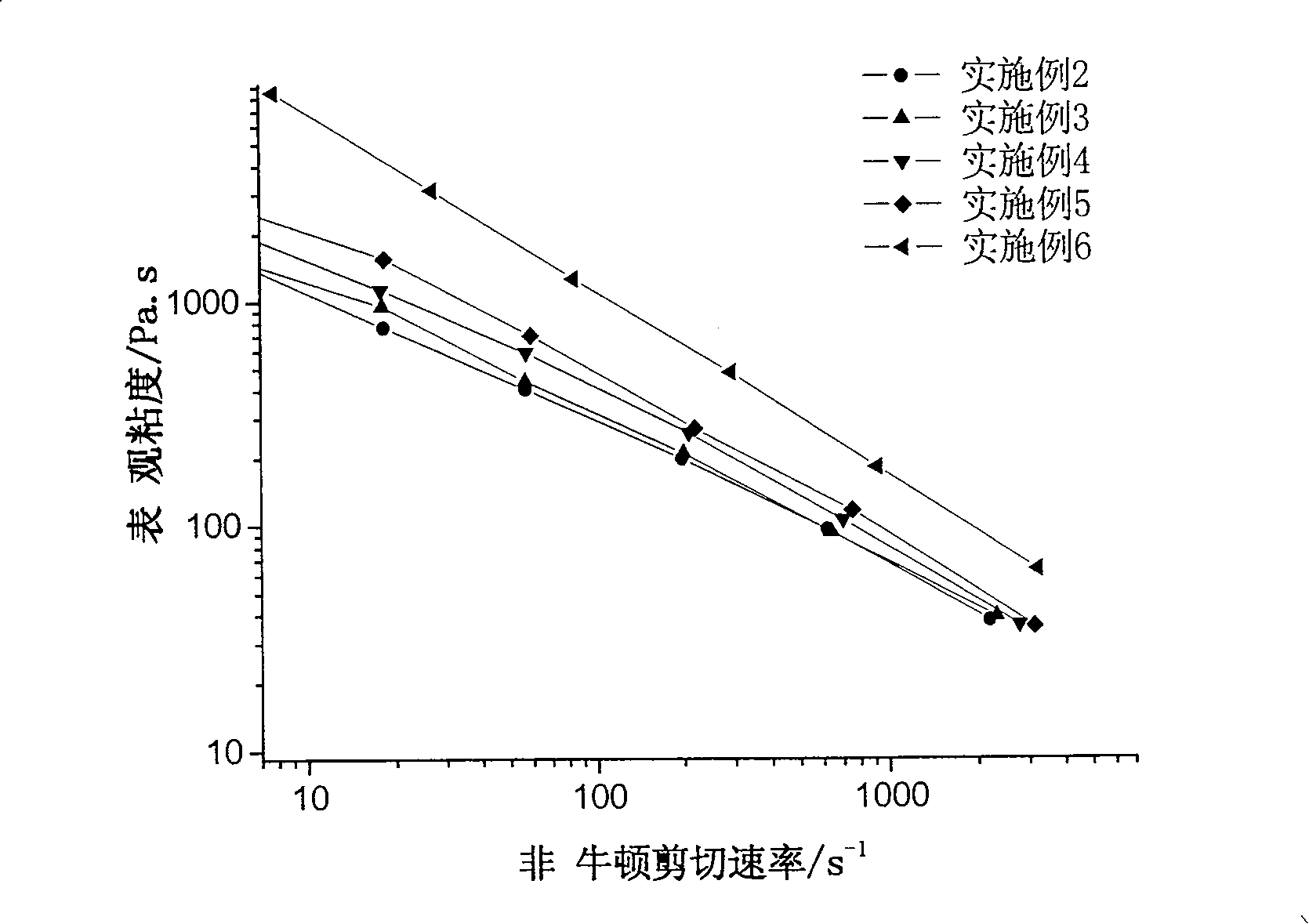

[0034] A 70 / 30 NBR-PP blend thermoplastic vulcanizate was prepared. The difference from Example 1 is that the amount of the main plasticizer TOTM is changed to 50 g and the auxiliary plasticizer ESO 10 g is added, and the operation steps are the same as in Example 1. The physical and mechanical properties of TPV are shown in Table 1, and the rheological properties are shown in Table 1. figure 2 .

Embodiment 3

[0036] A 70 / 30 NBR-PP blend thermoplastic vulcanizate was prepared. The difference from Example 2 is that the amount of the auxiliary plasticizer ESO added becomes 20 g, and the operation steps are the same as in Example 2. The physical and mechanical properties of TPV are shown in Table 1, and the rheological properties are shown in Table 1. figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com