Carbon-based electrocatalyst and preparation method thereof

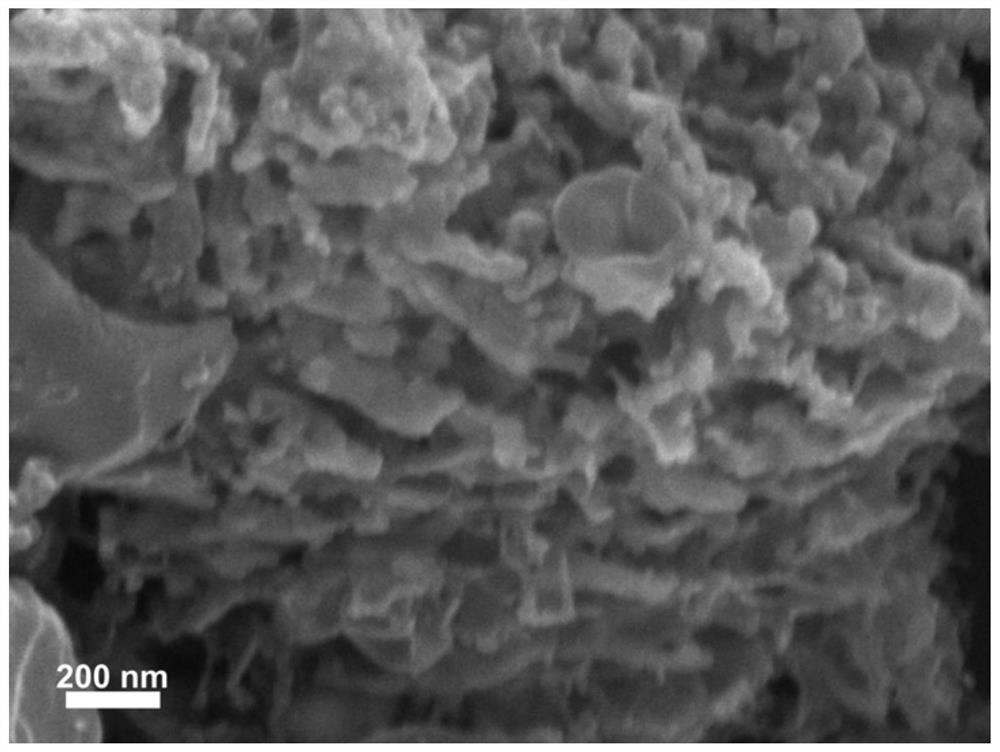

An electrocatalyst and electrocatalytic oxidation technology, which is applied in the field of electrocatalysis, can solve problems such as difficult to meet actual needs, poor electrocatalytic effect, and small specific surface area, and achieve performance improvement, large specific surface area, and increased specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A carbon-based electrocatalyst, its preparation method comprises the following steps:

[0048] 1) Wash the longan shell, put it in a drying oven and dry it at 100°C for 4 days, then put it into a high-speed pulverizer and pulverize it for 2 minutes, and pass through a 100-mesh sieve to obtain longan shell particles;

[0049] 2) 3 parts by mass of longan shell particles, 0.7 parts by mass of sodium chlorite, 0.4 parts by mass of cetyltrimethylammonium bromide and 40 parts by mass of distilled water were mixed and stirred for 5 minutes, and then added to the hydrothermal reaction kettle , heated up to 180°C for 12 hours, suction filtered, washed the filtered solid with water, dried in an oven at 100°C for 24 hours, added to a high-speed pulverizer for 2 minutes, and passed through a 100-mesh sieve to obtain hydrothermally activated longan shell particles;

[0050] 3) After mixing 12 parts by mass of hydrothermally activated longan shell particles, 2 parts by mass of potas...

Embodiment 2

[0053] A carbon-based electrocatalyst, its preparation method comprises the following steps:

[0054] 1) Wash the peanut shells, put them in a drying oven at 100°C and bake them for 6 days, then add them to a high-speed pulverizer and grind them for 5 minutes, pass through a 100-mesh sieve to obtain peanut shell particles;

[0055] 2) 5 parts by mass of peanut shell particles, 1 part by mass of sodium chlorite, 0.8 parts by mass of sodium lauroyl sarcosinate and 50 parts by mass of distilled water were mixed and stirred for 5 minutes, then added to a hydrothermal reaction kettle, and the temperature was raised to 200 React at ℃ for 16 hours, filter with suction, wash the filtered solid with water, put it in an oven and dry it at 100℃ for 24 hours, then add it to a high-speed pulverizer to grind for 2 minutes, pass through a 100-mesh sieve, and obtain hydrothermally activated peanut shell particles;

[0056] 3) After mixing 20 parts by mass of hydrothermally activated peanut sh...

Embodiment 3

[0059] A carbon-based electrocatalyst, its preparation method comprises the following steps:

[0060] 1) Wash the mangosteen shells, dry them in a drying oven at 100°C for 9 days, then put them into a high-speed pulverizer and pulverize them for 3 minutes, and pass through a 100-mesh sieve to obtain mangosteen shell particles;

[0061] 2) Mix and stir 10 parts by mass of mangosteen shell granules, 2 parts by mass of sodium chlorite, 2 parts by mass of polyvinylpyrrolidone and 80 parts by mass of distilled water for 5 minutes, then add to a hydrothermal reactor, and heat up to 160°C for 24 hours , suction filtration, washing the filtered solid with water, drying in an oven at 100°C for 24 hours, then putting it into a high-speed pulverizer to pulverize for 1 minute, and passing through a 100-mesh sieve to obtain hydrothermally activated mangosteen shell particles;

[0062] 3) 28 parts by mass of hydrothermally activated mangosteen shell particles, 4 parts by mass of potassium b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com