Preparation method of co-doped ternary positive electrode material

A positive electrode material and co-doping technology, applied in the field of preparation of lithium ion positive electrode materials, can solve the problems of poor electrochemical performance and stability of materials, irreversible phase transition, etc., to reduce technical costs, improve structural stability, and improve cycle The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

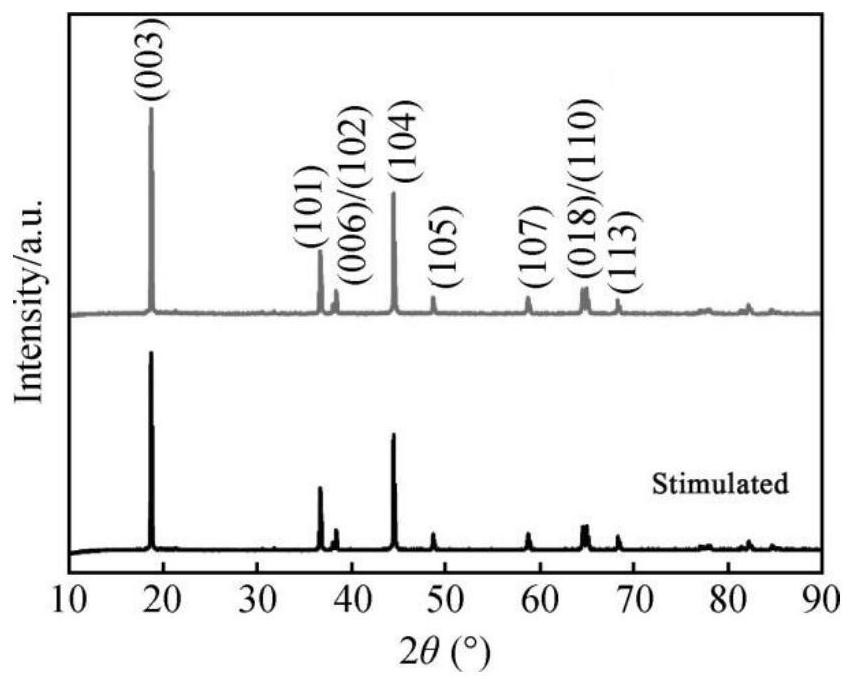

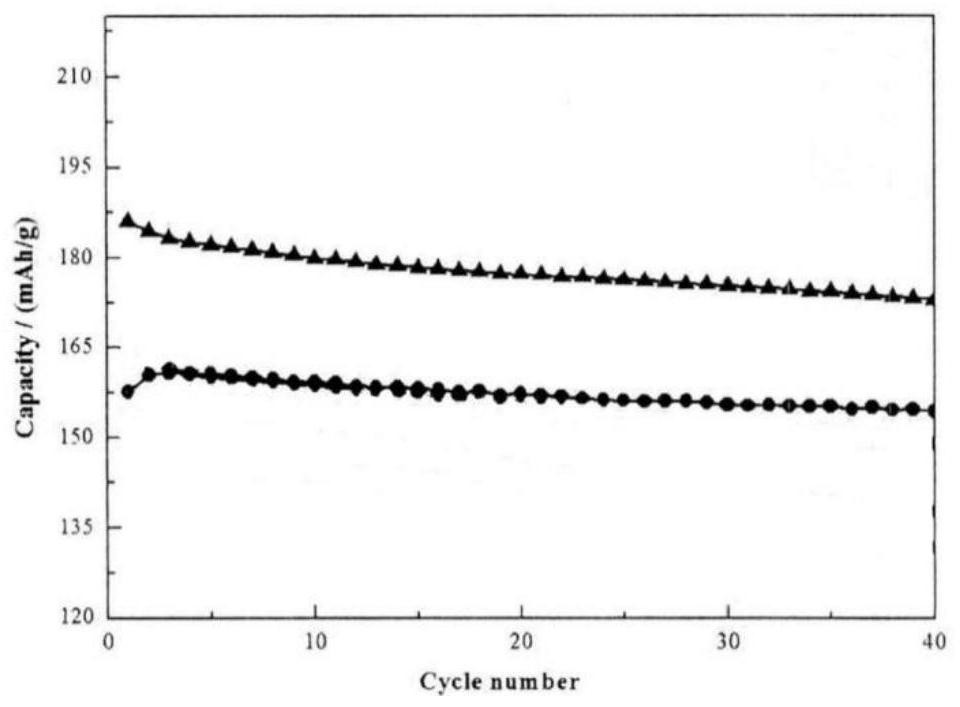

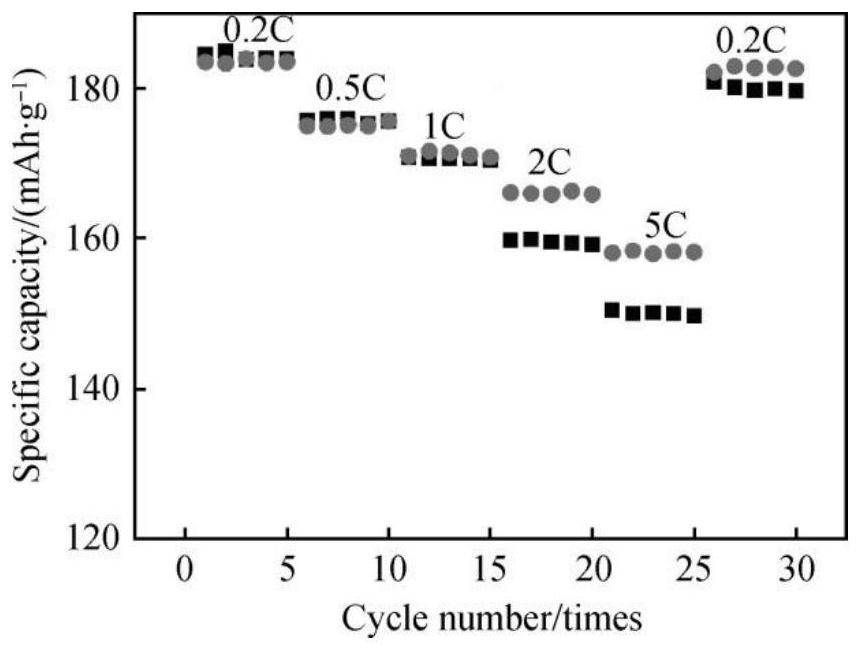

Image

Examples

Embodiment 1

[0032] A method for preparing a co-doped ternary positive electrode material, the specific steps are as follows:

[0033] S1: Mix nickel sulfate, cobalt sulfate and manganese sulfate according to the molar ratio Ni:Co:Mn=8:1:1 and add them to the deionized water, configure the concentration of the salt solution to be 2mol / L, and then add an equal volume ratio of 4mol / L 1 L of sodium hydroxide solution, then add 5 mol / L of ammonia water bottom solution, react in the reactor for 12 hours, filter the liquid with a suction filter, take the filter residue and put it in a drying box, dry it at 110 ° C for 12 hours, and obtain the precursor ( Ni 0.8 mn 0.1 co 0.1 o 2 )OH 2 .

[0034] S2: the precursor (Ni 0.8 mn 0.1 co 0.1 o 2 )OH 2 Grind with a mortar first, and then use a ball mill for secondary grinding. The grinding time is 4 hours, and then pass the precursor powder through a 200-mesh sieve to obtain the required precursor material.

[0035] S3: the precursor powder m...

Embodiment 2

[0039] A method for preparing a co-doped ternary positive electrode material, the specific steps are as follows:

[0040] S1: Mix nickel sulfate, cobalt sulfate and manganese sulfate according to the molar ratio Ni:Co:Mn=8:1:1 and add them to the deionized water, configure the concentration of the salt solution to be 2mol / L, and then add an equal volume ratio of 4mol / L 1 L of sodium hydroxide solution, then add 5 mol / L of ammonia water bottom solution, react in the reactor for 12 hours, filter the liquid with a suction filter, take the filter residue and put it in a drying box, dry it at 110 ° C for 12 hours, and obtain the precursor ( Ni 0.8 mn 0.1 co 0.1 o 2 )OH 2 .

[0041] S2: the precursor (Ni 0.8 mn 0.1 co 0.1 o 2 )OH 2 Grind with a mortar first, and then use a ball mill for secondary grinding. The grinding time is 4 hours, and then pass the precursor powder through a 200-mesh sieve to obtain the required precursor material.

[0042] S3: the precursor powder m...

Embodiment 3

[0046] A method for preparing a co-doped ternary positive electrode material, the specific steps are as follows:

[0047] S1: Mix nickel sulfate, cobalt sulfate and manganese sulfate according to the molar ratio Ni:Co:Mn=8:1:1 and add them to the deionized water, configure the concentration of the salt solution to be 2mol / L, and then add an equal volume ratio of 4mol / L 1 L of sodium hydroxide solution, then add 5 mol / L of ammonia water bottom solution, react in the reactor for 12 hours, filter the liquid with a suction filter, take the filter residue and put it in a drying box, dry it at 110 ° C for 12 hours, and obtain the precursor ( Ni 0.8 mn 0.1 co 0.1 o 2 )OH 2 .

[0048] S2: the precursor (Ni 0.8 mn 0.1 co 0.1 o 2 )OH 2 Grind with a mortar first, and then use a ball mill for secondary grinding. The grinding time is 4 hours, and then pass the precursor powder through a 200-mesh sieve to obtain the required precursor material.

[0049] S3: the precursor powder m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com