A high corrosion-resistant alloy flange and its preparation method

A corrosion-resistant alloy and corrosion-resistant coating technology, applied in flange connection, mechanical equipment, pipeline anti-corrosion/anti-rust protection, etc., can solve problems such as affecting the strength of alloy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

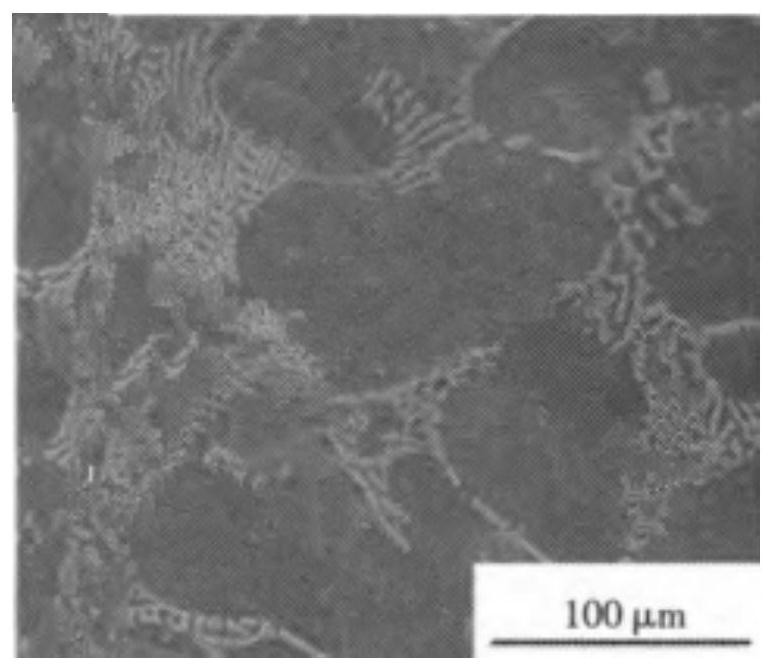

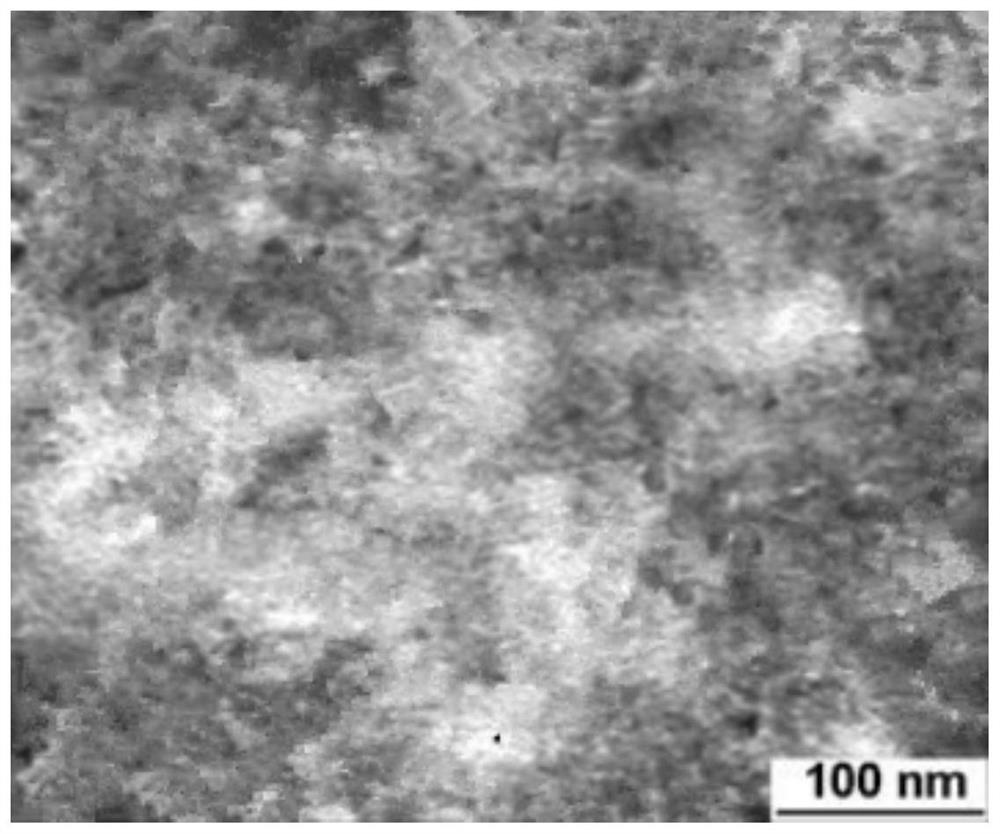

[0028] The high corrosion-resistant alloy flange includes an aluminum alloy substrate and a corrosion-resistant coating; the aluminum alloy substrate is composed of an aluminum-zinc borate whisker reinforcement phase and an Al-Zn-Mg alloy substrate; the corrosion-resistant coating is NiF 2 -TiF 4 -Ni coating.

[0029] The chemical composition of Al-Zn-Mg alloy includes: 5wt% Zn, 2wt% Mg, 1wt% Li, 1wt% Ca, 0.5wt% Cu, 0.1wt% Mo, 0.01wt% Y, 0.01wt% La, the balance is Al.

[0030] The mass ratio of Al-Zn-Mg alloy material to aluminum-zinc borate whiskers is 100:1.

[0031] The aluminum alloy matrix material is prepared by the following method:

[0032]S1. Weigh the raw materials of the Al-Zn-Mg alloy in proportion, melt them in a vacuum induction furnace protected by argon, and keep the alloy liquid at 670°C for 20 minutes;

[0033] S2. Put the powder obtained after pulverizing the aluminum-zinc borate whiskers into a stirring ball mill, fill it with liquid nitrogen, and start...

Embodiment 2

[0040] High corrosion-resistant alloy flanges include aluminum alloy materials and corrosion-resistant coatings, and the corrosion-resistant coatings are NiF 2 -TiF 4 - Ni coating; the aluminum alloy material is composed of aluminum zinc borate whisker reinforcement phase and Al-Zn-Mg alloy matrix.

[0041] The chemical composition of Al-Zn-Mg alloy includes: 12wt% Zn, 5wt% Mg, 3wt% Li, 2wt% Ca, 1.2wt% Cu, 0.2wt% Mo, 0.05wt% Y, 0.03wt% La, the balance is Al.

[0042] The mass ratio of Al-Zn-Mg alloy material to aluminum-zinc borate whiskers is 100:5.

[0043] The aluminum alloy matrix material is prepared by the following method:

[0044] S1. Weigh the raw materials of the Al-Zn-Mg alloy in proportion, melt them in a vacuum induction furnace protected by argon, and keep the alloy liquid at 700°C for 30 minutes;

[0045] S2. Put the powder obtained after pulverizing the aluminum-zinc borate whiskers into a stirring ball mill, fill it with liquid nitrogen, and start ball mil...

Embodiment 3

[0052] High corrosion-resistant alloy flanges include aluminum alloy materials and corrosion-resistant coatings, and the corrosion-resistant coatings are NiF 2 -TiF 4 - Ni coating; the aluminum alloy material is composed of aluminum zinc borate whisker reinforcement phase and Al-Zn-Mg alloy matrix.

[0053] The chemical composition of Al-Zn-Mg alloy includes: 7wt% Zn, 4wt% Mg, 2wt% Li, 2wt% Ca, 1wt% Cu, 0.15wt% Mo, 0.03wt% Y, 0.02wt% La, and the balance is Al .

[0054] The mass ratio of Al-Zn-Mg alloy material to aluminum-zinc borate whiskers is 100:3.

[0055] The aluminum alloy matrix material is prepared by the following method:

[0056] S1. Weigh the raw materials of the Al-Zn-Mg alloy in proportion, melt them in a vacuum induction furnace protected by argon, and keep the alloy liquid at 685°C for 25 minutes;

[0057] S2. Put the powder obtained after pulverizing the aluminum-zinc borate whiskers into a stirring ball mill, fill it with liquid nitrogen, and start ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com