Porphyrin covalent organic framework/graphene aerogel composite material as well as electrochemical sensor and application thereof

A graphene aerogel, covalent organic framework technology, applied in the direction of material electrochemical variables, scientific instruments, analytical materials, etc., can solve the problems of limiting the application of COF, low catalytic activity, etc., to achieve easy industrialization, high specific surface area , the effect of easy post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

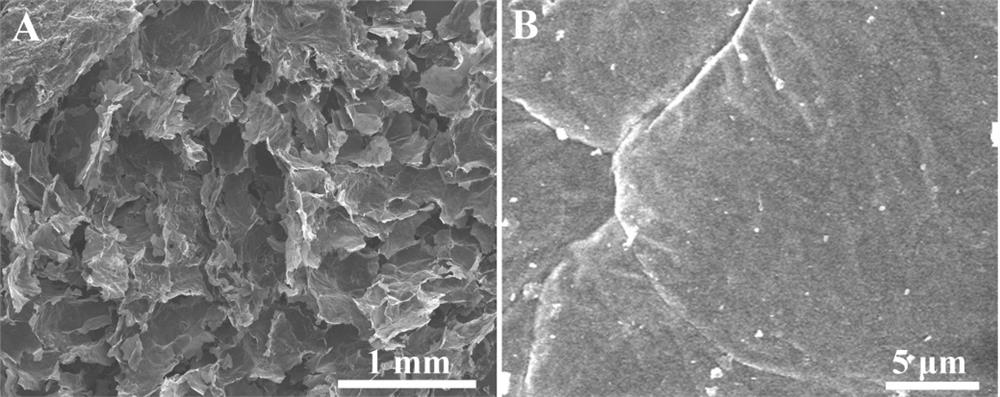

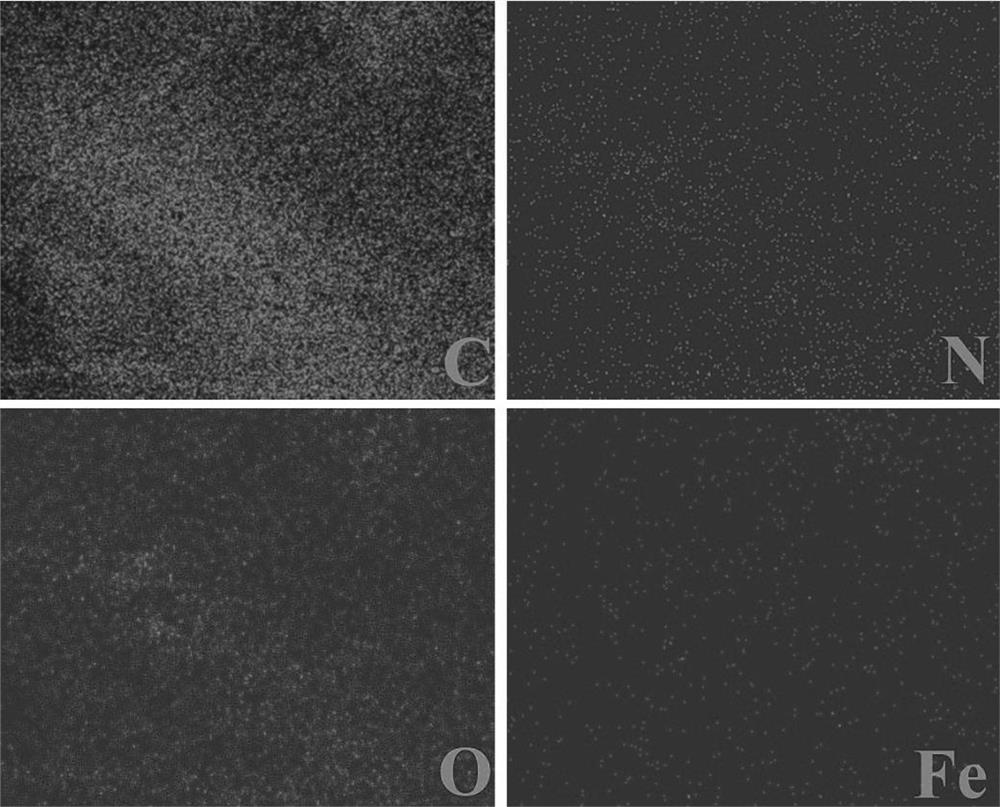

[0040] Example 1 Preparation method of porphyrin covalent organic framework / graphene airgel composite (COF-366-Fe / GA)

[0041] 1.1

[0042] (1) Graphene oxide was prepared into a 5 mg / mL aqueous solution in a beaker, freeze-dried for 24 hours and then taken out to obtain graphene oxide airgel;

[0043] (2) The graphene oxide airgel was reduced with 80% hydrazine hydrate solution at 90 °C for 24 hours, and then vacuum-dried for 24 hours to obtain reduced graphene oxide airgel (GA);

[0044] (3) Add GA (10 mg), 5,10,15,20-tetrakis(4-aminophenyl) porphyrin iron Fe(TAPP) (14.6 mg), terephthalaldehyde (5.6 mg), mesitylene (0.5 mL), ethanol (0.5 mL) and acetic acid aqueous solution (6 M, 0.1 mL) were added to a heat-resistant glass tube, ultrasonicated for 30 minutes, then degassed three times, sealed, and the reaction was heated at 120 °C 72 hours;

[0045] (4) After the reaction is completed, a deep purple precipitate is produced at the bottom of the tube, and the product is ob...

Embodiment 2

[0059] Example 2 Preparation of Nitric Oxide Electrochemical Sensor

[0060] 2.1

[0061] 2 mg porphyrin covalent organic framework / graphene airgel composite COF-366-Fe / GA was uniformly dispersed in 375 μL ethanol and 125 μL deionized water solvent containing 2 μL naphthol (5 wt%). Subsequently, 5 μL of the prepared mixture was coated on the pretreated glassy carbon electrode and dried overnight at room temperature to obtain an electrochemical sensor for nitric oxide

[0062] 2.2

[0063] Take 4 mg porphyrin covalent organic framework / graphene airgel composite (COF-366-Fe / GA) and uniformly disperse it in 750 μL ethanol and 250 μL deionized water solvent containing 4 μL naphthol (5wt%) middle. Subsequently, 7 μL of the prepared mixture was coated on the pretreated glassy carbon electrode and dried overnight at room temperature to obtain an electrochemical sensor for nitric oxide.

Embodiment 3

[0064] Example 3 Performance Measurement of Nitric Oxide Electrochemical Sensor

[0065] A three-electrode system is adopted, the glassy carbon electrode coated with the COF-366-Fe / GA composite material prepared in Example 2 is used as the working electrode, the platinum wire is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, and the electrolyte The solution is 0.01 M PBS solution (pH7.4), and at the same time, it is necessary to prepare a PBS solution (1.8 mM) containing saturated nitric oxide, and use an electrochemical workstation to test its performance through various methods;

[0066] Using cyclic voltammetry, set the scan rate to 0.1 V / s, and the scan range to 0-1.2 V, and test the CV curves of the COF-366-Fe / GA modified glassy carbon electrode in different concentrations of nitric oxide solutions. see results Figure 8 , the results showed that in the concentration range of 0-432 μM, as the concentration increased, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com