Preparation method of reusable investment casting shell, shell and casting process

A technology of investment casting and investment molding, which is applied in casting molding equipment, manufacturing tools, casting molds, etc., can solve the problems of mold shell cracks, reduce the high-temperature strength of the mold shell, and pouring sticky molds, etc., and achieve high temperature expansion coefficient and fire resistance The effect of high strength and simplified cleaning procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below.

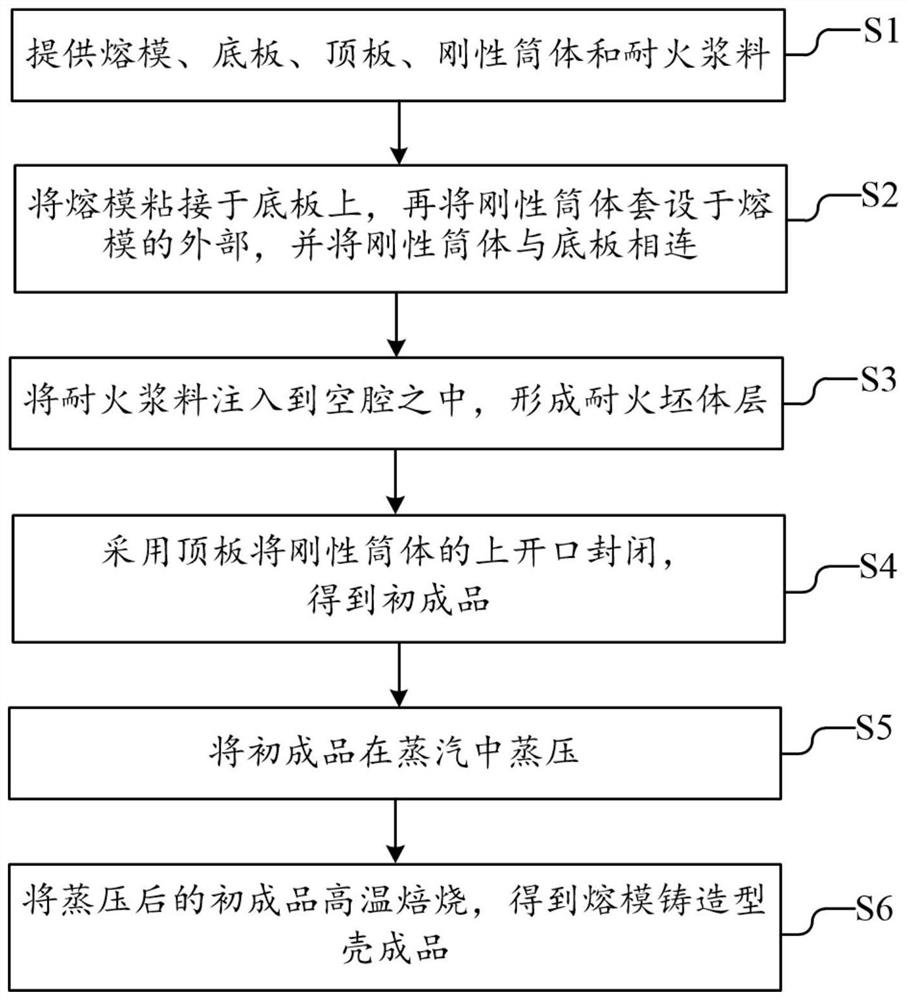

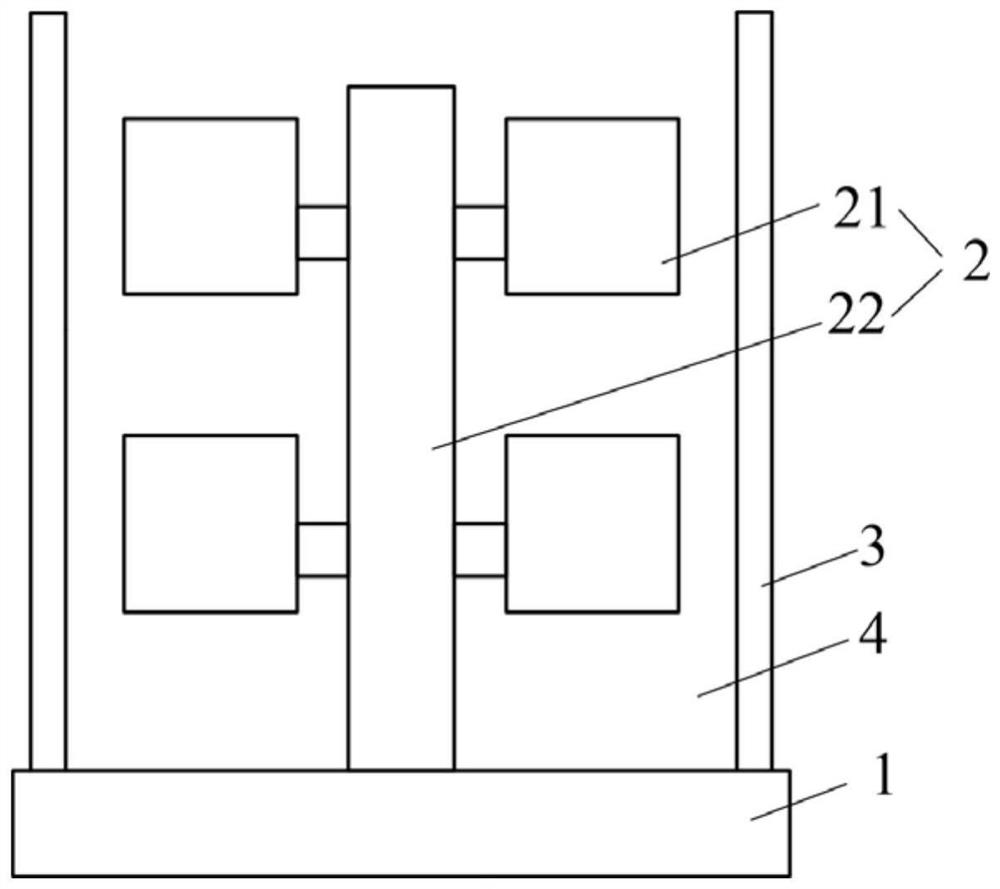

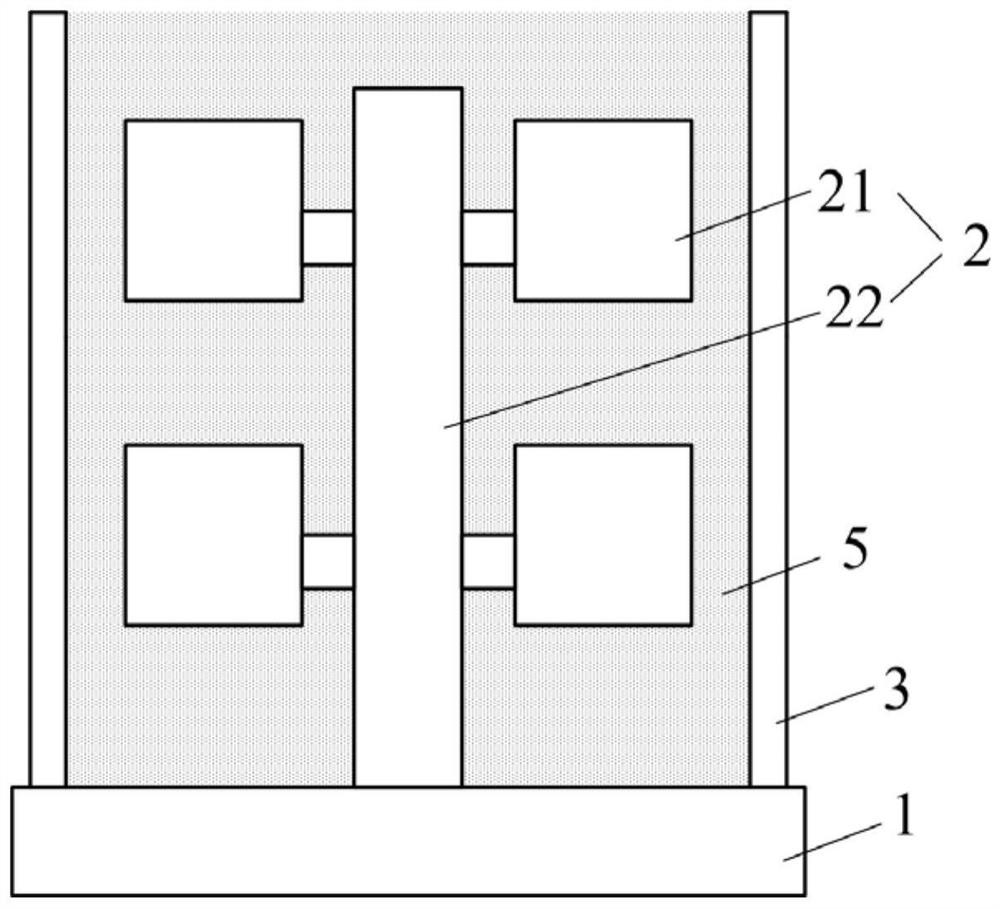

[0043] Conventional investment casting shells are difficult to reuse as shell materials, resulting in huge waste and increased production costs. For this reason, the present invention provides a kind of preparation method of reusable investment casting shell, see figure 1 , which includes the following steps:

[0044] S1: Provide investment pattern, bottom plate, top plate, rigid cylinder and refractory slurry;

[0045] The investment material can be wax-based molding material, rosin-based molding material, resin-based molding material or hybrid molding material, but not limited thereto; the investment model can be prepared by hot pressing method, 3D printing method, but not limited thereto. Preferably, in the present invention, resin-based molding material is selected as the investment mold material, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com