A kind of preparation method of fire door core board

A fire door core board, a certain amount of technology, applied in the direction of door leaves, windows/doors, ceramic products, etc., can solve the problems of fire doors losing their fire protection effect, affecting the overall performance of fire doors, and failing to reach the smoke toxicity index, etc., to achieve Good fire resistance, tight combination and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

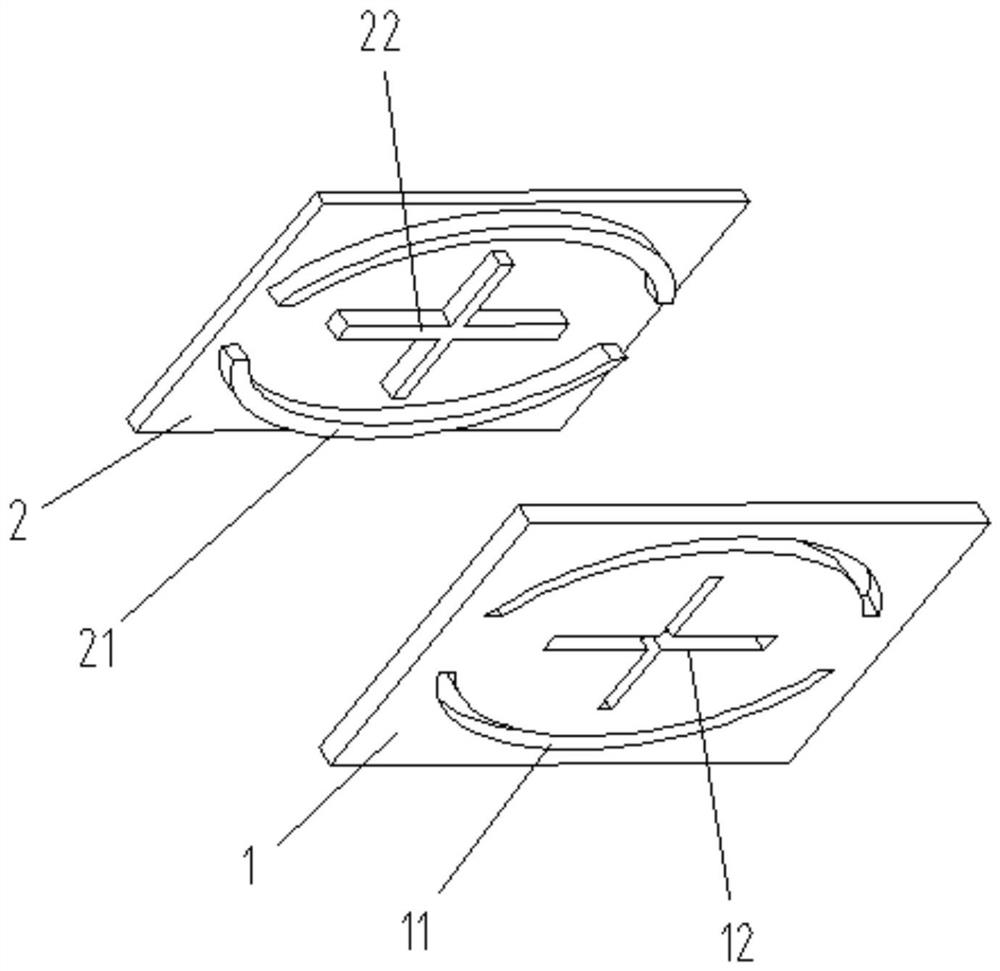

[0017] A method for preparing a fire door core board provided by the present invention is characterized in that MgCl2 is dissolved in a certain amount of water to prepare brine with a Baume degree of 25°Bé; after cooling the brine to below 40°C, pour Add ferrous sulfate and phosphoric acid and stir evenly; then add sodium tripolyphosphate, 801 glue, modifier and carbon fiber and stir again to obtain mixed solution A, wherein the modifier is fly ash; mix the foaming agent with water And fully foamed to obtain a mixed solution B, wherein the foaming agent is an AB type composite foaming agent; then the mixed solution A and the mixed solution B are evenly stirred and mixed to obtain a foam mixture F; in the foam mixture F, magnesium oxide is added in batches Stir and mix evenly to obtain a paste mixture E; pour the paste mixture E into a mold and press it through the mold cover plate. The mold cover plate includes a correspondingly arranged base plate 1 and a flat plate 2, a cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com