A kind of anti-skinning prefabricated brick

A technology of prefabricated bricks and anti-skinning, which is applied in the field of refractory materials in the building materials industry, and can solve problems such as easy skinning on the side walls of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

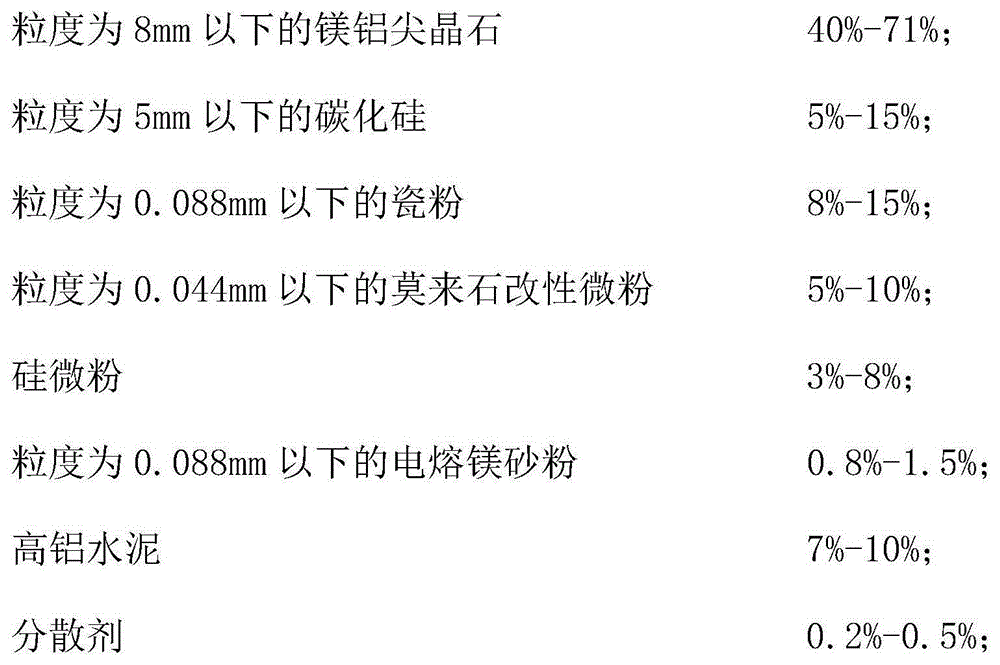

Method used

Image

Examples

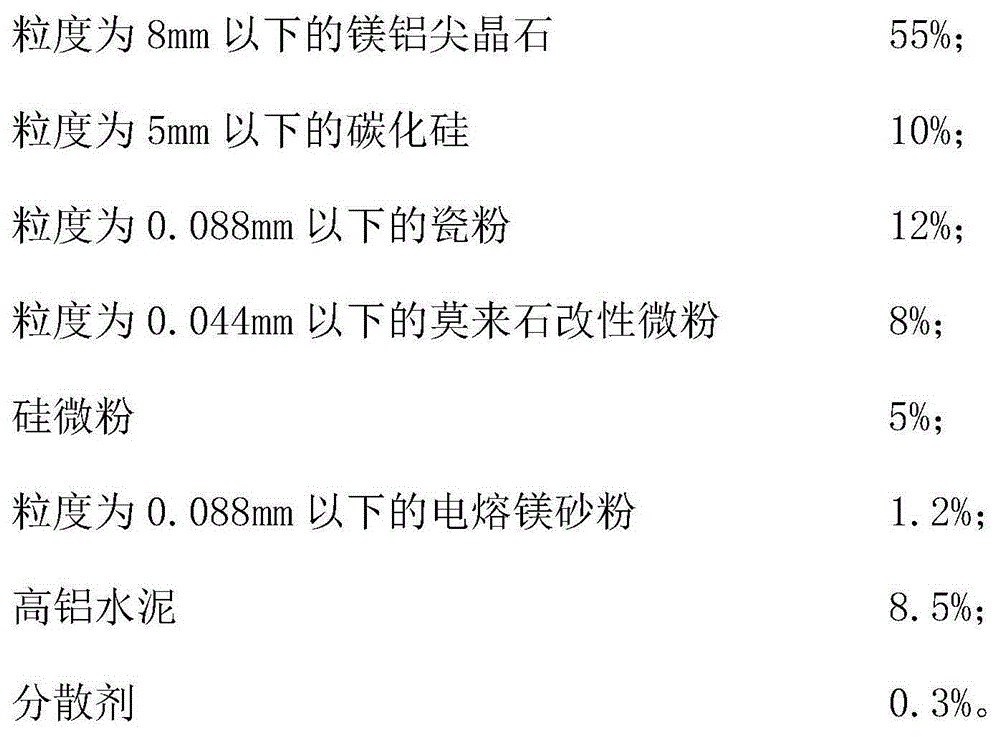

Embodiment 1

[0027] A formula for anti-skinning prefabricated bricks, the anti-skinning prefabricated bricks include the following components and the mass percentage of each component is: magnesia-alumina spinel 55%, silicon carbide 10%, porcelain powder 12%, mullite 8% stone modified micropowder, 5% silica micropowder, 1.2% fused magnesia powder, 8.5% high alumina cement and 0.3% dispersant.

[0028] Al in anti-skinning prefabricated bricks 2 o 3 The content is less than or equal to 40%, SiO 2 The content is less than or equal to 37%. Mullite modified micropowder includes mullite ore powder, natural sintered mullite, artificially synthesized mullite and kaolin sintered mullite, mullite ore powder, natural sintered mullite, Synthetic mullite and kaolin sintered mullite contains metakaolin, and metakaolin includes five-coordinated activated aluminum. The dispersant is Na 5 P 3 o 10 or Na 6 o 18 P 6 .

[0029] The particle size of magnesium aluminum spinel is 0-8mm, the particle si...

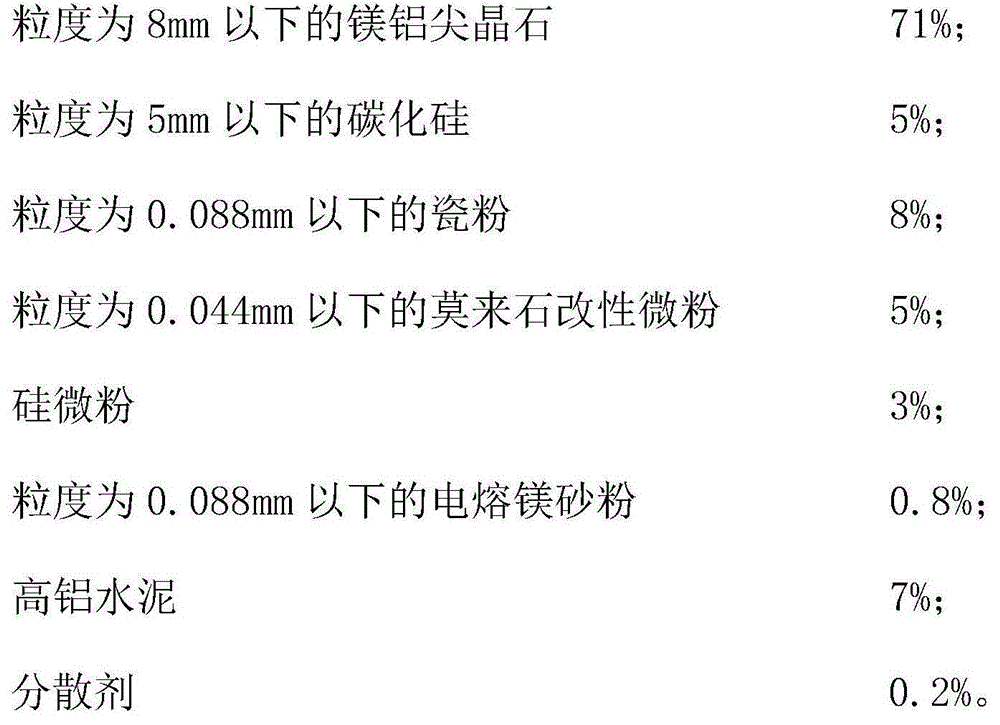

Embodiment 2

[0038] The difference from Example 1 is that the anti-skinning prefabricated brick of this example includes the following components and the mass percentage of each component is: magnesia-alumina spinel 71%, silicon carbide 5%, porcelain powder 8%, mullite Stone modified micropowder 5%, silica micropowder 3%, fused magnesia powder 0.8%, high alumina cement 7% and dispersant 0.2%.

[0039] The anti-skinning prefabricated brick produced in this embodiment has a compressive strength of 92.30 MPa and an anti-demolition strength of 18.63 MPa in an environment of 110°C. The anti-skinning prefabricated brick produced in this embodiment has a compressive strength of 112.30 MPa and an anti-demolition strength of 25.63 MPa in an environment of 1100°C.

Embodiment 3

[0041] The difference from Example 1 is that the anti-skinning prefabricated brick of this example includes the following components and the mass percentage of each component is: magnesia-alumina spinel 40%, silicon carbide 15%, porcelain powder 15%, mullite 10% stone modified micropowder, 8% silica micropowder, 1.5% fused magnesia powder, 10% high alumina cement and 0.5% dispersant.

[0042] The anti-skinning prefabricated brick produced in this embodiment has a compressive strength of 83.30 MPa and an anti-demolition strength of 16.73 MPa in an environment of 110°C. The anti-skinning prefabricated brick produced in this embodiment has a compressive strength of 94.23MPa and an anti-demolition strength of 19.31MPa in an environment of 1100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com