Mixed-phase titanium dioxide modified high-nickel ternary positive electrode material as well as preparation method and application thereof

A titanium dioxide and cathode material technology, which is applied in the field of mixed-phase titanium dioxide modified high-nickel ternary cathode material and its preparation, can solve problems such as poor crystallinity, and achieve the effects of improving rate performance, inhibiting surface side reactions, and inhibiting cation mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

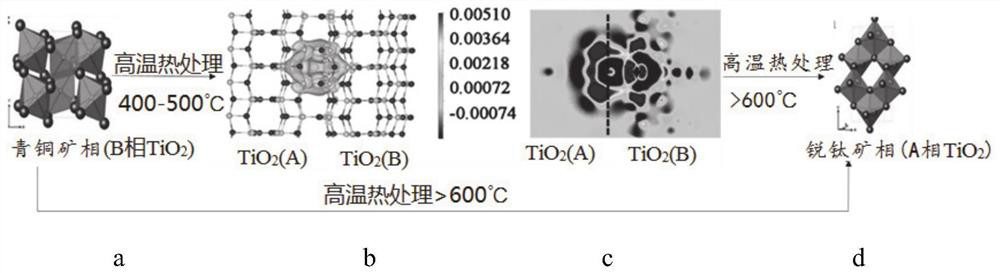

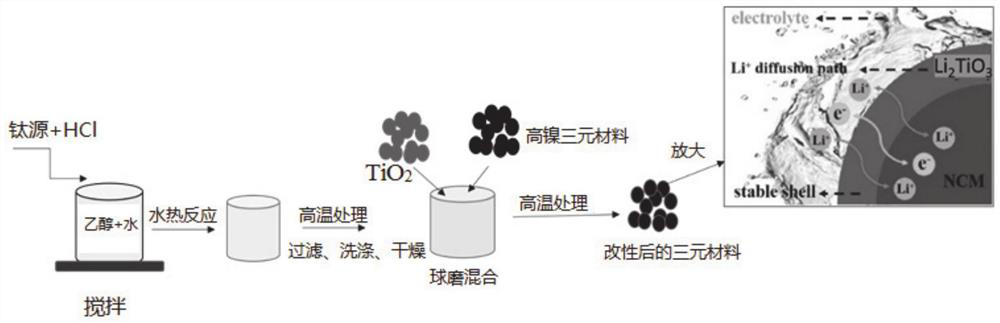

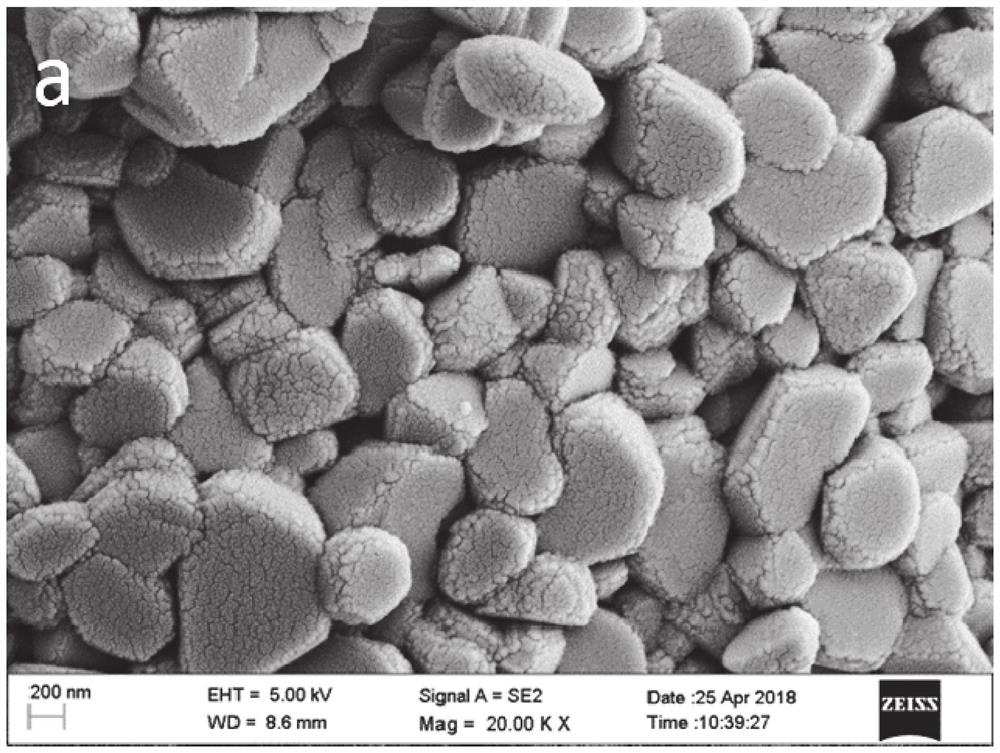

[0049] Dissolve 2ml of isopropyl titanate and n-butyl titanate in hydrochloric acid solution to form an 18% mixed solution, add it to 60ml of ethylene glycol and 30ml of aqueous solution, stir for 15min, and then transfer to polytetrafluoroethylene In a lined reactor, keep warm at 150°C for 5 hours, cool to room temperature, filter with suction and wash and dry repeatedly with ethanol and water to obtain the precursor; heat-treat the precursor at 500°C in nitrogen for 4 hours to obtain a miscible TiO 2 (Type A) / TiO 2 (Type B); the miscible TiO 2 (Type A) / TiO 2 (Type B) and LiNi 0.8 co 0.1 mn 0.1 o 2 Mix at a mass fraction of 3%, ball mill and mix for 30 minutes at a rotational speed of 300r / min, and then heat-treat at 500°C for 10 hours in an oxygen atmosphere to obtain TiO 2 (Type A) / TiO 2 (Type B) LiNi modified by doping and coating 0.8 co 0.1 mn 0.1 o 2 Cathode material.

Embodiment 2

[0054] Dissolve 2ml of isopropyl titanate and n-butyl titanate in hydrochloric acid solution to form an 18% mixed solution, add it to 60ml of ethylene glycol and 30ml of aqueous solution, stir for 15min, and then transfer to polytetrafluoroethylene In a lined reactor, keep warm at 140°C for 5 hours, cool to room temperature, filter with suction and wash and dry repeatedly with ethanol and water to obtain TiO 2 precursor; the TiO 2 The precursor was heat-treated at 460 °C for 4 hours in nitrogen to obtain miscible TiO 2 (Type A) / TiO 2 (Type B); the miscible TiO 2 (Type A) / TiO 2 (Type B) and LiNi 0.8 co 0.1 mn 0.1 o 2 Mix at a mass fraction of 3%, ball mill and mix for 30 minutes at a rotational speed of 300r / min, and then heat-treat at 500°C for 10 hours in an oxygen atmosphere to obtain TiO 2 (Type A) / TiO 2 (Type B) LiNi modified by doping and coating 0.8 co 0.1 mn 0.1 o 2 Cathode material.

Embodiment 3

[0056] Dissolve 2ml of isopropyl titanate and n-butyl titanate in hydrochloric acid solution to form an 18% mixed solution, add it to 60ml of ethylene glycol and 30ml of aqueous solution, stir for 15min, and then transfer to polytetrafluoroethylene In a lined reactor, keep warm at 150°C for 5 hours, cool to room temperature, filter with suction and wash and dry repeatedly with ethanol and water to obtain TiO 2 (Type B) precursor; the TiO 2 (Type B) The precursor was heat-treated at 500 °C for 4 hours in nitrogen to obtain miscible TiO 2 (Type A) / TiO 2 (Type B); the miscible TiO 2 (Type A) / TiO 2 (Type B) and LiNi 0.8 co 0.1 mn 0.1 o 2 Mix according to the mass fraction of 3%, ball mill and mix for 30 minutes at a speed of 300r / min, and then heat-treat at 530°C for 10 hours in an oxygen atmosphere to obtain TiO 2 (Type A) / TiO 2 (Type B) LiNi modified by doping and coating 0.8 co 0.1 mn 0.1 o 2 Cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com