Method used for preparing ethanol via direct hydrogenation of acetic acid

A direct hydrogen preparation technology, applied in the preparation of hydroxyl compounds, organic compounds, physical/chemical process catalysts, etc., to achieve the effects of reducing volume, prolonging service life and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

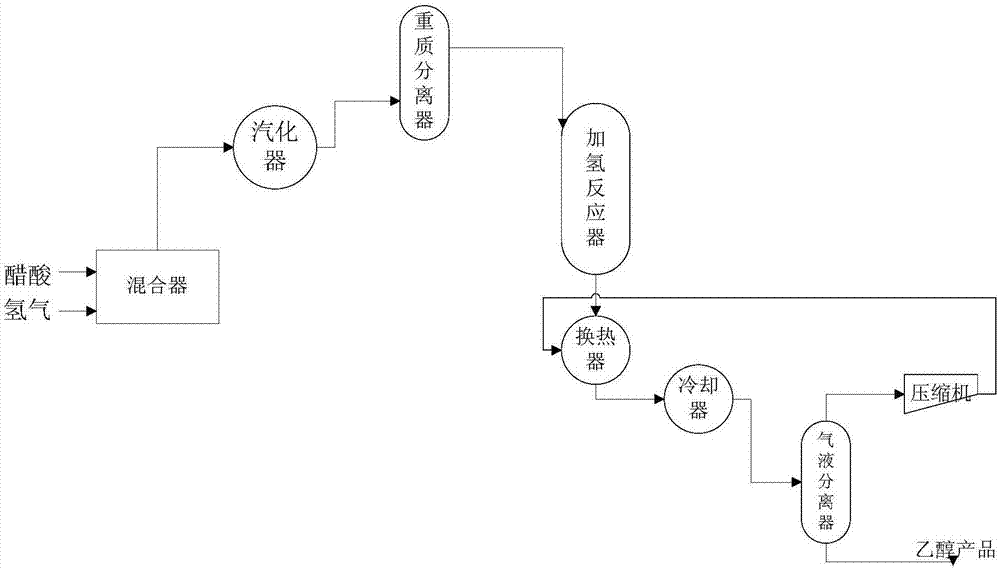

[0043] Such as figure 1 Shown, the technique that the direct hydrogenation of acetic acid of the present embodiment prepares ethanol is,

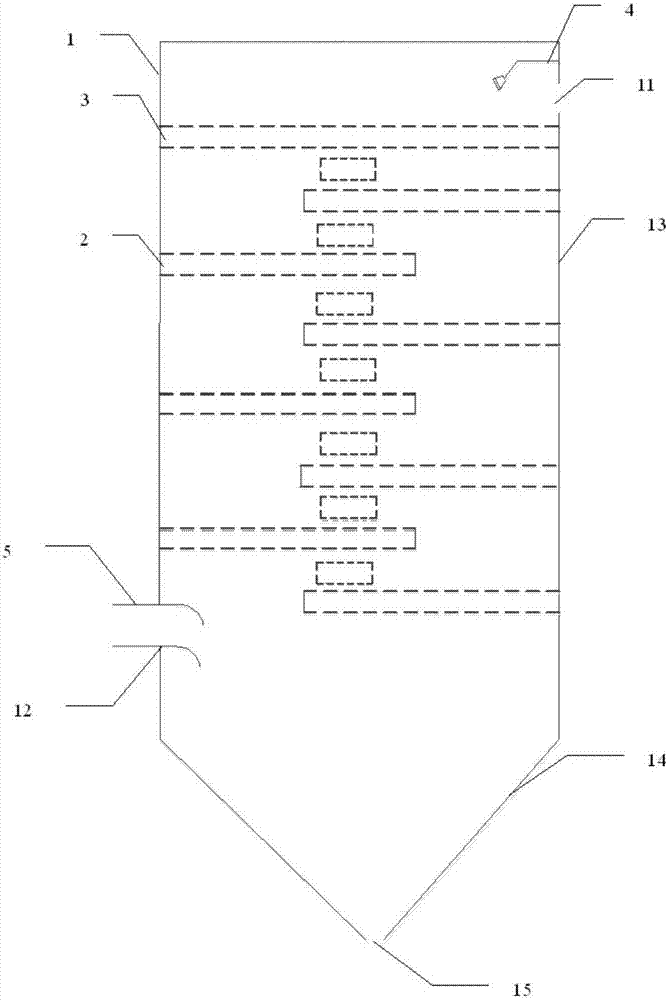

[0044] (1) Mixing the acetic acid raw material and hydrogen with a molar ratio of 1:20 in a mixer, the mixed gas is transported into the vaporizer and gasified to obtain the raw material mixed gas, and the raw mixed material mixture is transported to the heavy separator ( Such as figure 2 shown) to remove dust and liquid droplets in the raw material mixture.

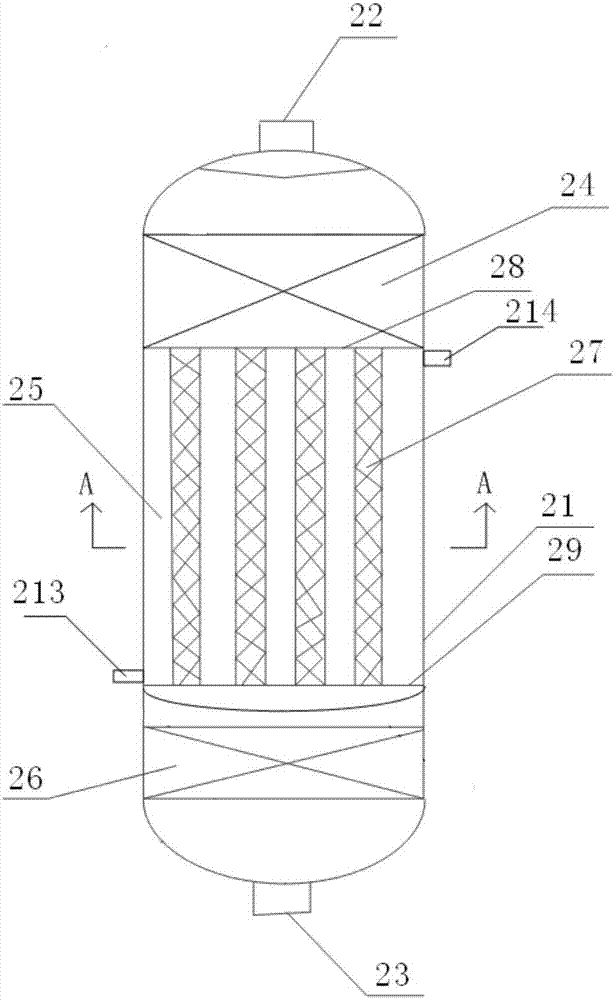

[0045] (2) Under the action of a hydrogenation catalyst, the raw material mixture that removes dust and liquid droplets is passed into a hydrogenation reactor (such as image 3 and 4 Shown) to carry out the reaction, the control reaction temperature is 280 ℃, and the reaction pressure is 2.0MPa;

[0046] (3) cooling the reactant of the step (2), and separating crude ethanol and a hydrogen-containing gas phase, in order to improve the utilization rate of heat and reduce energy con...

Embodiment 2

[0056] The process of preparing ethanol by the direct hydrogenation of acetic acid of the present embodiment is,

[0057] (1) Mixing the acetic acid raw material and hydrogen with a molar ratio of 1:30 in the mixer, the mixed gas is transported into the vaporizer and gasified to obtain the raw material mixed gas, and the raw mixed material mixture is transported to the heavy separator ( Such as figure 2 shown) to remove dust and liquid droplets in the raw material mixture.

[0058] (2) Under the action of a hydrogenation catalyst, the raw material mixture that removes dust and liquid droplets is passed into a hydrogenation reactor (such as image 3 and 4 Shown) to carry out the reaction, the control reaction temperature is 210 ℃, and the reaction pressure is 3.0MPa;

[0059] (3) cooling the reactant of the step (2), and separating crude ethanol and a hydrogen-containing gas phase, in order to improve the utilization rate of heat and reduce energy consumption, the reactant o...

Embodiment 3

[0070] Such as figure 1 Shown, the technique that the direct hydrogenation of acetic acid of the present embodiment prepares ethanol is,

[0071] (1) The acetic acid raw material and the hydrogen gas with a molar ratio of 1:40 are mixed in a mixer, and the mixed gas is transported into a vaporizer for gasification to obtain a raw material mixed gas, and the raw mixed material mixture is transported to a heavy separator ( Such as figure 2 shown) to remove dust and liquid droplets in the raw material mixture.

[0072] (2) Under the action of a hydrogenation catalyst, the raw material mixture that removes dust and liquid droplets is passed into a hydrogenation reactor (such as image 3 and 4 Shown) to carry out the reaction, the control reaction temperature is 290 ℃, and the reaction pressure is 4.0MPa;

[0073](3) cooling the reactant of the step (2), and separating crude ethanol and a hydrogen-containing gas phase, in order to improve the utilization rate of heat and reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com