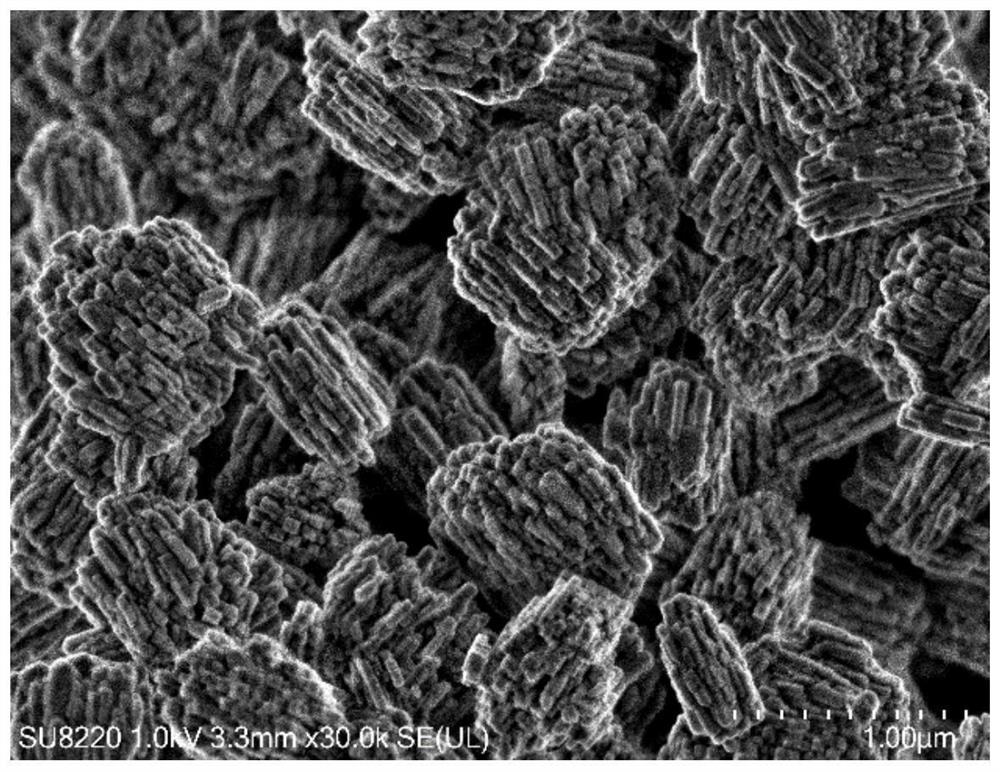

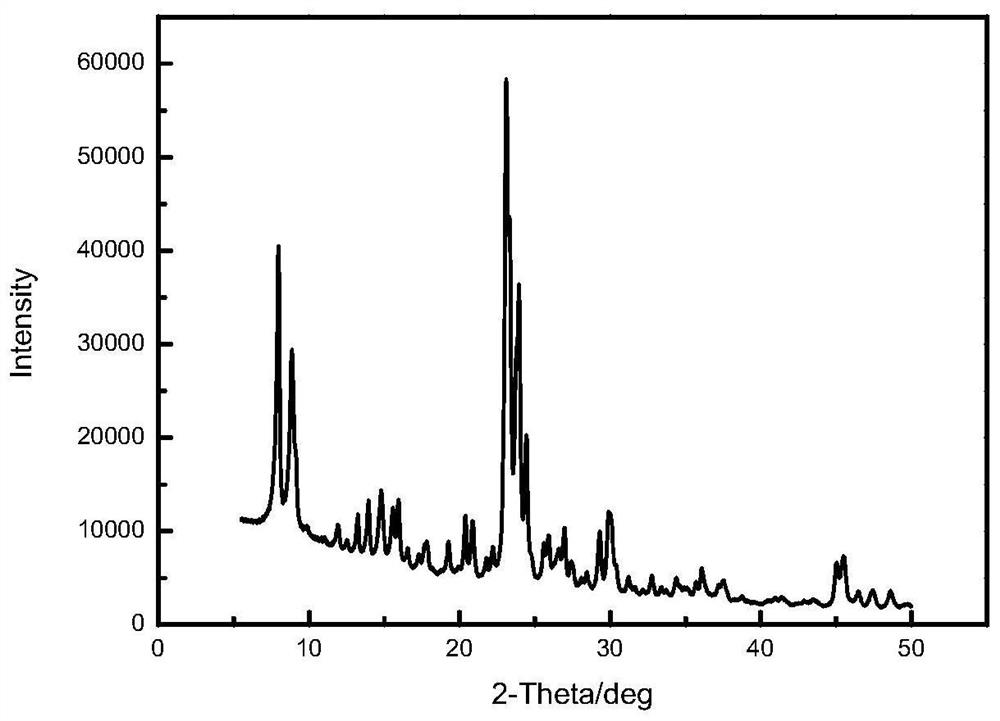

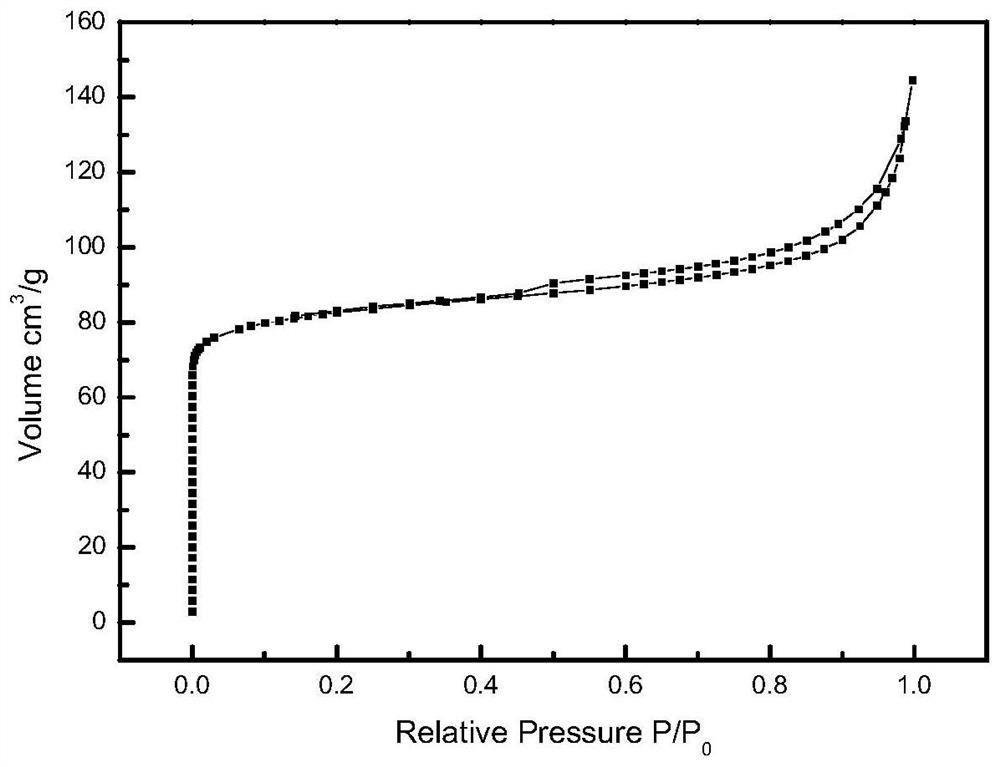

Preparation method of ZSM-5 nanosheet aggregate grown through directional piling

A technology of ZSM-5 and nano-flakes, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of uncontrollable growth direction of ZSM-5 aggregates, and shorten the crystallization time , Reduce synthesis energy consumption, uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060]This embodiment provides a method for preparing ZSM-5 nano flake agglomerates, the preparation method includes:

[0061]The silica sol, tetrapropylammonium bromide, ethylamine and deionized water were mixed according to a molar ratio of 1:0.2:1.2:18. The mixing was stirring and mixing in a water bath at 30°C for 30 minutes, and the resulting mixed solution was heated at 100 Crystallize at ℃ for 36 hours to obtain nano crystallite emulsion;

[0062]The sodium hydroxide and aluminum sulfate octahydrate are mixed and dissolved in water, and silica sol is added dropwise to obtain a silica-aluminum hybrid gel. The silica-aluminum hybrid gel is stirred in a 30°C water bath for 30 minutes, and the silica sol, The molar ratio of inorganic base, aluminum source and water is 1:0.01:0.08:10;

[0063]The nano-microcrystalline emulsion was added dropwise to the silica-aluminum hybrid gel and stirred for 30 minutes. The addition amount of the nano-microcrystalline emulsion was 0.7 of the mass of sil...

Embodiment 2

[0067]This embodiment provides a method for preparing ZSM-5 nano flake agglomerates, the preparation method includes:

[0068]The silica sol, tetrapropylammonium bromide, triethanolamine and deionized water were mixed according to a molar ratio of 1:0.3:1.4:18, and the mixing was stirring and mixing in a water bath at 30°C for 30 minutes, and the resulting mixed solution was heated at 90 Crystallize at ℃ for 36 hours to obtain nano crystallite emulsion;

[0069]The sodium hydroxide and aluminum sulfate octahydrate are mixed and dissolved in water, and silica sol is added dropwise to obtain a silica-aluminum hybrid gel. The silica-aluminum hybrid gel is stirred in a 30°C water bath for 30 minutes, and the silica sol, The molar ratio of inorganic base, aluminum source and water is 1:0.01:0.10:25;

[0070]The nano-microcrystalline emulsion was added dropwise to the silica-aluminum hybrid gel and stirred for 30 minutes. The addition amount of the nano-microcrystalline emulsion was 0.8 of the mas...

Embodiment 3

[0074]This embodiment provides a method for preparing ZSM-5 nano flake agglomerates, the preparation method includes:

[0075]The silica sol, tetrapropylammonium bromide, ethylenediamine, and deionized water were mixed according to a molar ratio of 1:0.4:1.8:25, and the mixing was stirring and mixing in a water bath at 30°C for 30 minutes, and the resulting mixed solution Crystallize at 120°C for 24 hours to obtain nanocrystalline emulsion;

[0076]Sodium carbonate and aluminum sulfate octahydrate are mixed and dissolved in water, and silica sol is added dropwise to obtain a silica-aluminum hybrid gel. The silica-aluminum hybrid gel is stirred in a water bath at 30°C for 30 minutes. The molar ratio of alkali, aluminum source and water is 1:0.01:0.14:25;

[0077]The nano-microcrystalline emulsion was added dropwise to the silica-aluminum hybrid gel and stirred for 30 minutes. The addition amount of the nano-microcrystalline emulsion was 0.5 of the mass of silica in the silica-aluminum hybrid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com