Preparation method of organic layered bimetallic silicate

A bimetallic and organic layer technology, applied in silicon organic compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as poor dispersion, high temperature and high pressure, expensive precious metals, etc., to achieve Synthesis of low energy consumption and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The present embodiment provides a preparation method of organic layered bimetallic silicate, and the preparation method includes the following steps:

[0065] Prepare FeCl according to the molar ratio of Table 1 3 ·6H 2 O, CuCl 2 ·2H 2 O, 3-aminopropyltriethoxysilane. First of all, Table 1 shows the different proportions of FeCl at room temperature 3 ·6H 2 O and CuCl 2 ·2H 2 Add O into ethanol to dissolve, ultrasonically disperse for 2-10 min, and after mixing evenly, add 3-aminopropyltriethoxysilane dropwise to it to form a precipitated slurry. Then, stirring was performed in a magnetic stirrer at a rotational speed of 600-1000 r / min for 12-24 h. After the reaction, the mixture was centrifuged at 4000-8000 r / min for 5 min, washed twice with ethanol to remove residual ferric chloride and cupric chloride, and then dried at 40°C to obtain the samples of Examples 1-7.

[0066] Table 1 Element ratios corresponding to examples 1-7

[0067]

[0068] A series of c...

Embodiment 2

[0075] The present embodiment provides a preparation method of organic layered bimetallic silicate, and the preparation method includes the following steps:

[0076] Prepare MnCl according to the molar ratio of Table 2 2 ·4H 2 O, CuCl 2 ·2H 2 O, 3-aminopropyltriethoxysilane. First, different ratios of MnCl were mixed at room temperature 2 ·4H 2 O and CuCl 2 ·2H 2 Add O into ethanol to dissolve, ultrasonically disperse for 2-10 min, and after mixing evenly, add 3-aminopropyltriethoxysilane dropwise to it to form a precipitated slurry. Then, stir with a magnetic stirrer at a rotational speed of 600-1000 r / min for 12-20 h. After the reaction, the mixture was centrifuged at 4000-8000 r / min for 5 min, washed twice with ethanol to remove residual manganese chloride and copper chloride, and then dried at 40°C to obtain the samples of Examples 8-12.

[0077] Table 2 Element ratios corresponding to examples 8-12

[0078]

[0079]

[0080] A series of characterizations, ...

example 8

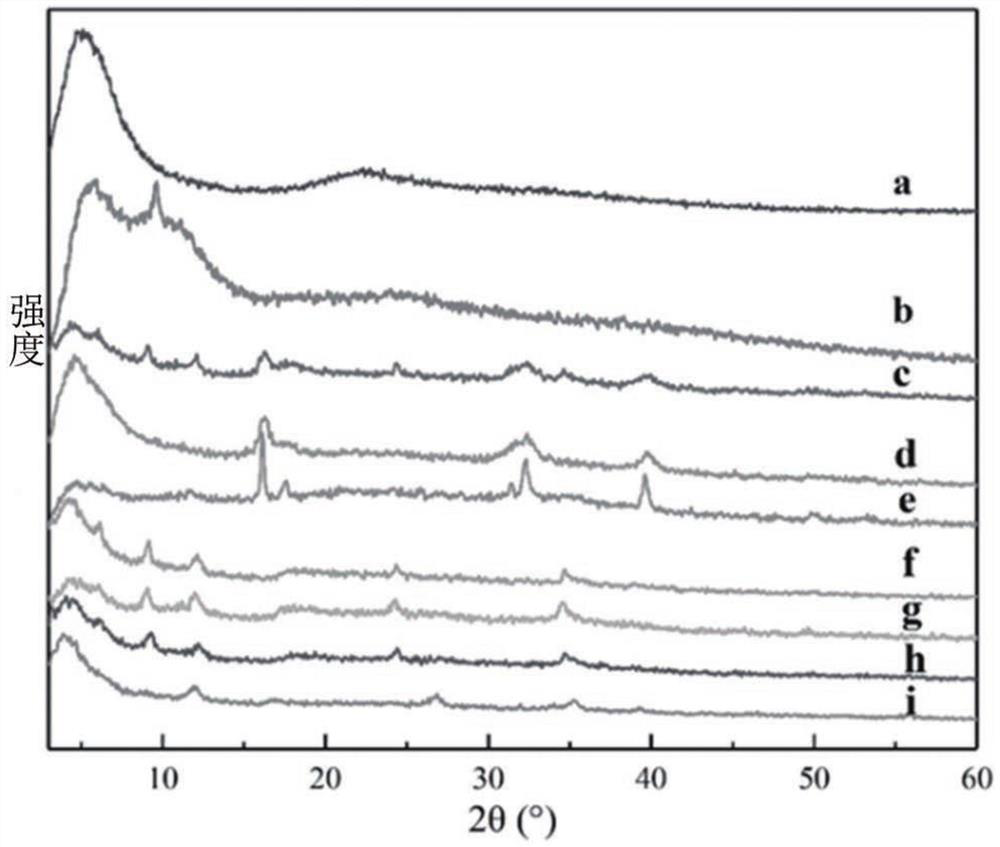

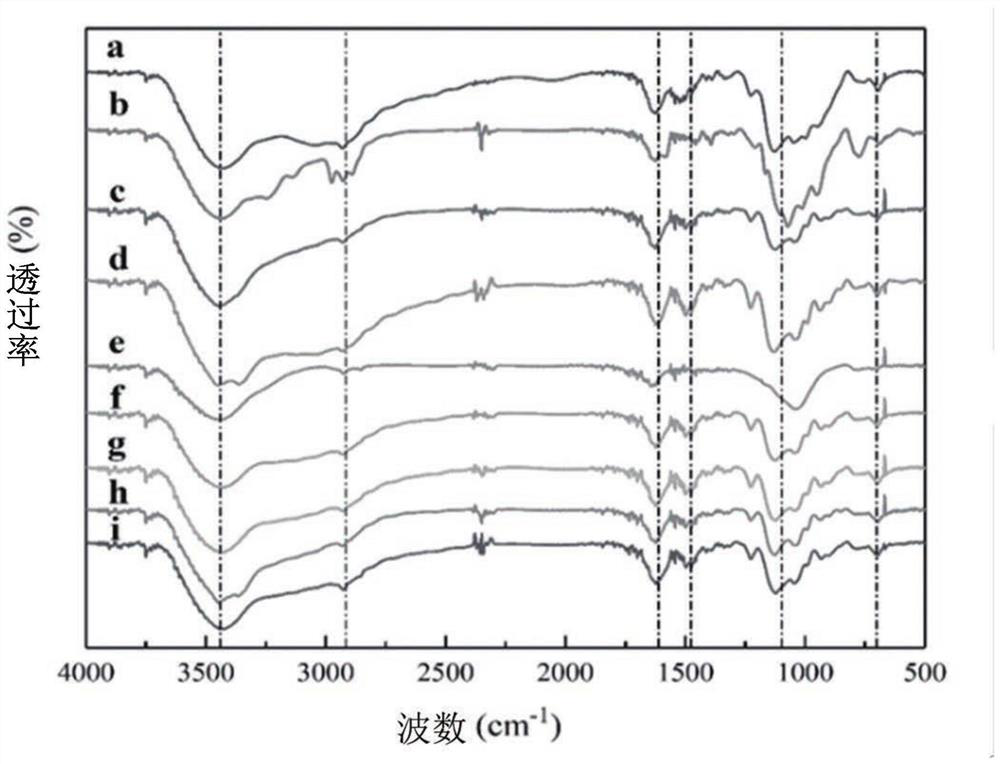

[0081] First, as Figure 3a As shown, the crystal structures of monometallic layered silicates (OMP (manganese but no copper), OCP (copper but no manganese)) and different ratios of OMCP were investigated by XRD as comparative samples. Figure 3a , the curves and their meanings are: a.OCP, b.OMCP-1:7 (Example 8), c.OMCP-1:3 (Example 9), d.OMCP-1:1 (Example 10), e .OMCP-3:1 (Example 11), f.OMCP-7:1 (Example 12), g.OMP.

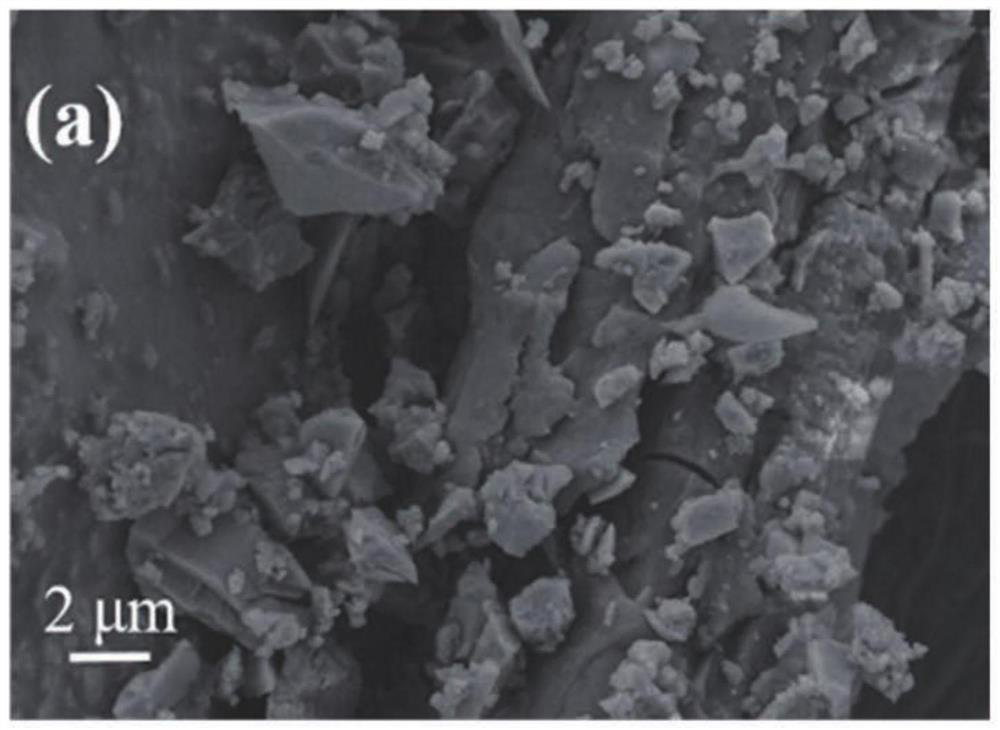

[0082] The XRD patterns of bimetallic OMCP have a similar trend to that of monometallic layered silicates. 001 = 1.5-1.8 nm) with typical characteristic fronts of layered organoclay structure; and with the gradual increase of iron content, the d of OMCP 001 The surface characteristic peaks gradually shifted to lower angles, and the interlayer spacing increased accordingly. Furthermore, the peaks of organic layered bimetallic silicates were not split compared to monometallic layered silicates, suggesting that bimetallic OMCP is a single phase, rather than mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com