Welding device for electrical engineering wire connection

A wire connection and welding device technology, applied in auxiliary devices, welding equipment, metal processing and other directions, can solve the problems of inability to accurately control the soldering temperature, insufficient soldering, and small diameter of the heating pipe, and to solve the inability to accurately control the temperature. , The effect of uniform heating and convenient mobile operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific structure of the wire bonding device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

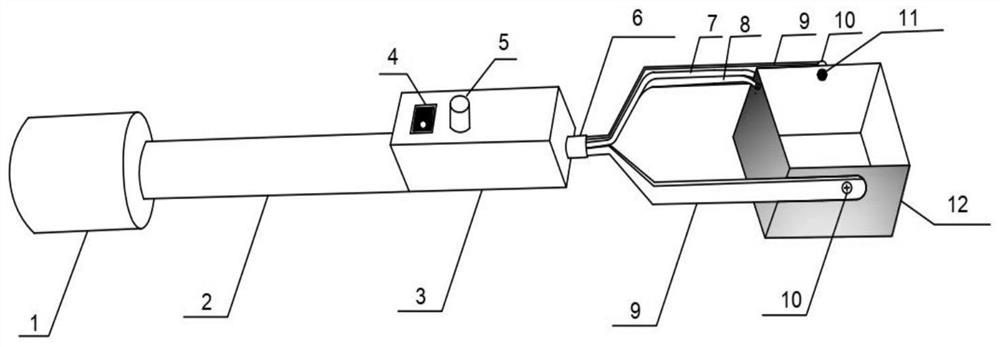

[0021] Such as figure 1 Shown is a schematic diagram of the overall structure of the wire bonding device of the present invention.

[0022] The wire welding device has a handle 2, a power socket 1 is fixed at the end of the handle 2, and a thermostat 3 is connected to the front end of the handle 2, and a short tube 6 is arranged on the front end of the thermostat 3. A U-shaped support 9 is fixed, and the U-shaped support 9 is connected with a tin pot 12 with a heating element. The power socket 1 arranged at the end of the handle 2 is a single-phase power socket with a protective ground jack, and the protective ground jack and the two power supply jacks are arranged in a zigzag shape. The temperature controller 3 has a square insulating shell, the rear part of the square insulating shell is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com