Treatment method of pre-lithiated SiOx negative electrode material

A technology of negative electrode material and processing method, which is applied in the processing field of pre-lithiated SiOx negative electrode material and can solve the problems of poor stability of pre-lithiated SiOx negative electrode material and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

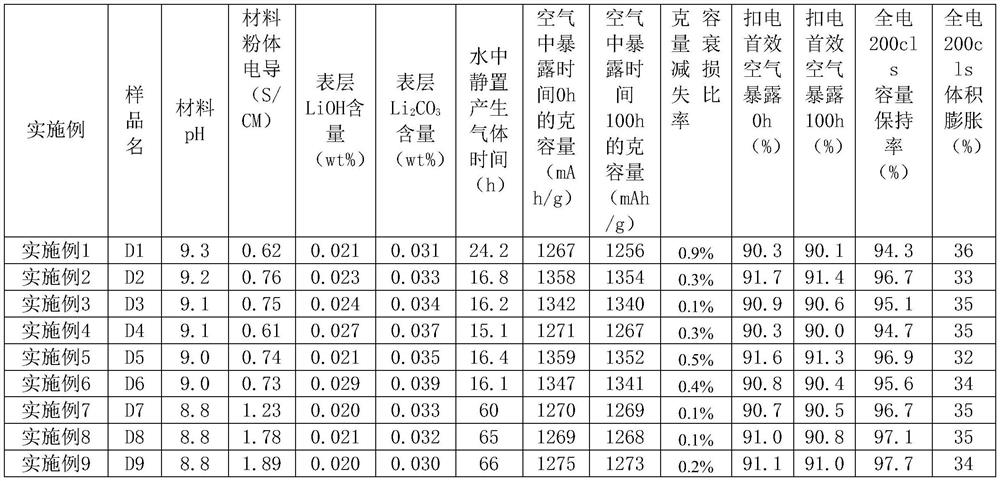

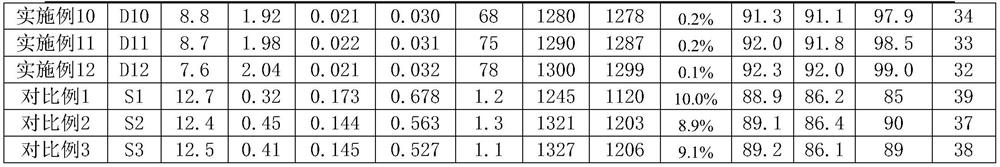

Examples

Embodiment 1

[0058] The processing method of the pre-lithiated SiO negative electrode material of the present embodiment is as follows:

[0059] 1) Mix 100g 6μm SiO with 10g Li 2 O was mixed by mechanical ball milling for 3 hours, and then calcined at 500°C for 2 hours under the protection of nitrogen in an inert atmosphere to obtain a pre-lithiated SiOx negative electrode material, which was designated as sample S1;

[0060] Take 100g of S1 with a particle size of 6 μm and a carbon coating amount of 3wt%, and take NH 4 F 5g, stir at room temperature for 1 hour, mix well, then put the mixed sample in a tube furnace, feed nitrogen gas at a rate of 50mL / min, start heating to 190°C after half an hour of nitrogen gas feeding, the heating rate Control the temperature at 30°C / min, raise the temperature to 190°C, keep it warm for 0.5h, grind and sieve the obtained powder, and finally obtain a pre-lithiated SiOx negative electrode material coated with a layer of LiF on the surface, which is desig...

Embodiment 2

[0062] The processing method of the pre-lithiated SiO negative electrode material of the present embodiment is as follows:

[0063] Mix 10g of biphenyl with 100g of tetrahydrofuran, then add 0.5g of metal lithium powder to obtain an organic solution containing metal lithium, then add 10g of 6μm SiO, stir for 12h, filter, and wash with tetrahydrofuran to obtain a pre-lithiated SiOx negative electrode material, which is denoted as Sample S2;

[0064] Take 100g of S2 with a particle size of 6 μm and a carbon coating amount of 3wt%, and take NH 4 F 5g, stir at room temperature for 1 hour, mix well, then put the mixed sample in a tube furnace, feed nitrogen gas at a rate of 50mL / min, start heating to 190°C after half an hour of nitrogen gas feeding, the heating rate Control the temperature at 30°C / min, raise the temperature to 190°C, keep it warm for 0.5h, grind and sieve the obtained powder, and finally obtain a pre-lithiated SiOx negative electrode material coated with a layer o...

Embodiment 3

[0066] The processing method of the pre-lithiated SiO negative electrode material of the present embodiment is as follows:

[0067] Mix 100g of 6μm SiO negative electrode with 5g of metallic lithium powder, then add 100g of electrolyte to it, and let it stand at room temperature for 12h to obtain the pre-lithiated SiOx negative electrode material, which is designated as sample S3, wherein the solute of the electrolyte is 1.2mol / L Lithium hexafluorophosphate, the solvent is ethylene carbonate EC;

[0068] Take 100g of S3 with a particle size of 6 μm and a carbon coating amount of 3wt%, and take NH 4 F 5g, stir at room temperature for 1 hour, mix well, then put the mixed sample in a tube furnace, feed nitrogen gas at a rate of 50mL / min, start heating to 190°C after half an hour of nitrogen gas feeding, the heating rate Control the temperature at 30°C / min, raise the temperature to 190°C, keep it warm for 0.5h, grind and sieve the obtained powder, and finally obtain a pre-lithiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com