Metal lithium composite material and preparation method thereof

A composite material and lithium metal technology, which is applied in electrode manufacturing, electrode rolling/calendering, electrode heat treatment, etc., can solve the problems of difficult processing, lithium composite electrodes, and low coulombic efficiency of lithium metal negative electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing the above-mentioned metal composite material, comprising: S1) heating and mixing the lithium-philic oxide and pure lithium, and rolling after cooling to obtain metal lithium modified foil; An organic solution containing a metal salt is soaked to obtain a treated three-dimensional conductive material; the metal salt is selected from one or more of aluminum salts, tin salts, antimony salts, zinc salts, and magnesium salts; S2) the After the metal lithium modified foil is mechanically combined with the treated three-dimensional conductive material, heat treatment is carried out in a protective atmosphere; the metal lithium composite material is obtained.

[0037]On the one hand, the present invention modifies pure metallic lithium into metallic lithium by adding lithium-philic oxides to introduce more active sites during the cycle, improve its cycle performance, and enhance its electrochemical stability. On the othe...

Embodiment 1

[0049] Pure lithium and tin dioxide are mixed at a mass ratio of 1:0.5 at 250°C for a uniform time (30 minutes). After cooling, they are rolled into metal lithium modified foils by mechanical rolling.

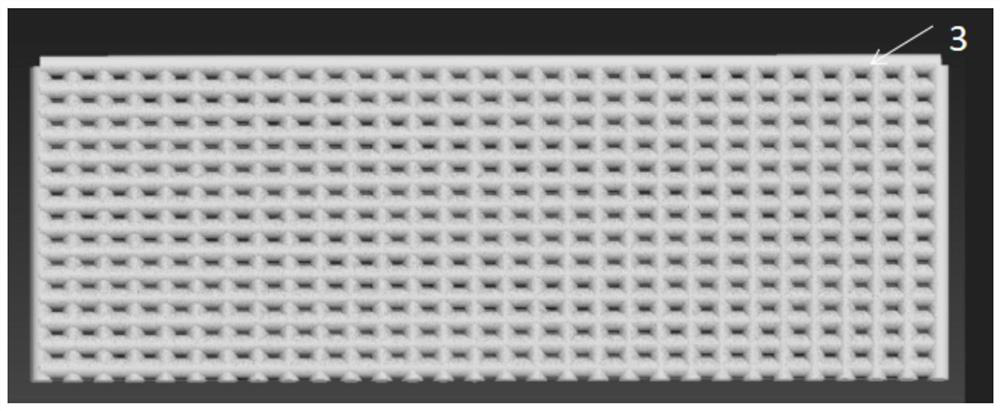

[0050] A three-dimensional conductive carbon cloth with a porosity of 50% and a thickness of 150 μm is used.

[0051] Using a concentration of 0.1mol / L SbCl 3 The above-mentioned three-dimensional conductive carbon cloth is soaked in ethanol solution for 10mins, and dried, wherein SbCl 3 The mass ratio of the salt mass to the carbon cloth material is 0.5, and a three-dimensional conductive carbon cloth after soaking is obtained.

[0052] The soaked three-dimensional conductive carbon cloth was heat-treated at 300° C. for 30 minutes in an air environment to obtain a heat-treated three-dimensional conductive carbon cloth.

[0053] Set the areal density to 5mg / cm 2 The lithium foil is pasted on the three-dimensional conductive carbon cloth after the heat treatment, the mass rat...

Embodiment 2

[0061] Mix pure lithium and silicon dioxide at a mass ratio of 1:1, heat and mix evenly at 350°C (time 20min), and after cooling, roll it into metal lithium modified foil.

[0062] A three-dimensional conductive copper mesh with a porosity of 30% and a thickness of 500 μm is used.

[0063] With a concentration of 1mol / L Al(NO 3 ) 2 The above-mentioned three-dimensional conductive copper mesh is soaked in acetone solution, soaked for 1h, and then dried to obtain the three-dimensional conductive copper mesh after the soaking treatment, wherein Al(NO 3 ) 2 The mass ratio of salt mass to carbon cloth material is 1.

[0064] The three-dimensional conductive copper mesh after the soaking treatment was heat-treated at 400° C. for 120 minutes in an argon atmosphere to obtain a heat-treated three-dimensional conductive copper mesh.

[0065] Set the areal density to 10mg / cm 2The metal lithium modified foil material is pasted on the three-dimensional conductive copper mesh after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com