Component analysis and sample preparation method of grain boundary diffusion type neodymium iron boron

A technology of grain boundary diffusion and component analysis, which is applied in the direction of analysis of materials, preparation of test samples, sampling, etc., can solve the problems of complex sample preparation and process for component analysis, long digestion process, insufficient digestion, etc., to achieve easy operation, The effect of short time, shortened process and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

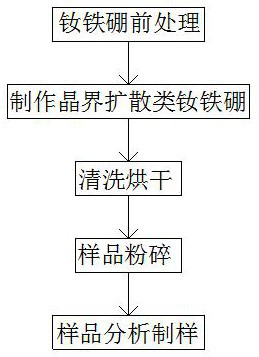

Image

Examples

Embodiment 1

[0032] Embodiment 1: A sample preparation method for component analysis of NdFeB-like grain boundary diffusion, comprising the following steps:

[0033] S1, NdFeB pretreatment

[0034] Select a piece of NdFeB sheet with a thickness of 5mm, and use the corresponding treatment liquid to carry out surface treatment on the selected NdFeB sheet to remove surface stains, then rinse with distilled water, and then dry the surface by drying equipment to obtain the foundation For NdFeB flakes, the treatment solution is hydrochloric acid solution or nitric acid solution, the treatment time of the treatment solution is 4-8 minutes, and the drying time of the drying equipment is 3-6 minutes.

[0035] S2. Making grain boundary diffusion NdFeB

[0036] The basic NdFeB flakes obtained after pretreatment are prepared by grain boundary diffusion to obtain grain boundary diffusion-like NdFeB flakes. The preparation methods of grain boundary diffusion include evaporation diffusion, magnetron spu...

Embodiment 2

[0045] Embodiment 2: A sample preparation method for component analysis of NdFeB-like grain boundary diffusion, comprising the following steps:

[0046] S1, NdFeB pretreatment

[0047]Select a piece of NdFeB sheet with a thickness of 6mm, and use the corresponding treatment liquid to carry out surface treatment on the selected NdFeB sheet to remove surface stains, then rinse with distilled water, and then dry the surface by drying equipment to obtain the foundation For NdFeB flakes, the treatment solution is hydrochloric acid solution or nitric acid solution, the treatment time of the treatment solution is 4-8 minutes, and the drying time of the drying equipment is 3-6 minutes.

[0048] S2. Making grain boundary diffusion NdFeB

[0049] The basic NdFeB flakes obtained after pretreatment are prepared by grain boundary diffusion to obtain grain boundary diffusion-like NdFeB flakes. The preparation methods of grain boundary diffusion include evaporation diffusion, magnetron sput...

Embodiment 3

[0058] Embodiment 3: A sample preparation method for component analysis of NdFeB-like grain boundary diffusion, comprising the following steps:

[0059] S1, NdFeB pretreatment

[0060] Select a piece of NdFeB sheet with a thickness of 6.5 mm, and use the corresponding treatment liquid to carry out surface treatment on the selected NdFeB sheet to remove surface stains, then rinse with distilled water, and then dry the surface by drying equipment to obtain For basic NdFeB flakes, the treatment solution is hydrochloric acid solution or nitric acid solution, the treatment time of the treatment solution is 4-8 minutes, and the drying time of the drying equipment is 3-6 minutes.

[0061] S2. Making grain boundary diffusion NdFeB

[0062] The basic NdFeB flakes obtained after pretreatment are prepared by grain boundary diffusion to obtain grain boundary diffusion-like NdFeB flakes. The preparation methods of grain boundary diffusion include evaporation diffusion, magnetron sputterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com