Vanadium extraction method of sodium-modified vanadium extraction tailings

A technology for sodium extraction of vanadium and tailings, which is applied in the direction of improving process efficiency, can solve environmental pollution and other problems, and achieve the effects of high degree of cleanliness, good economic and social benefits, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

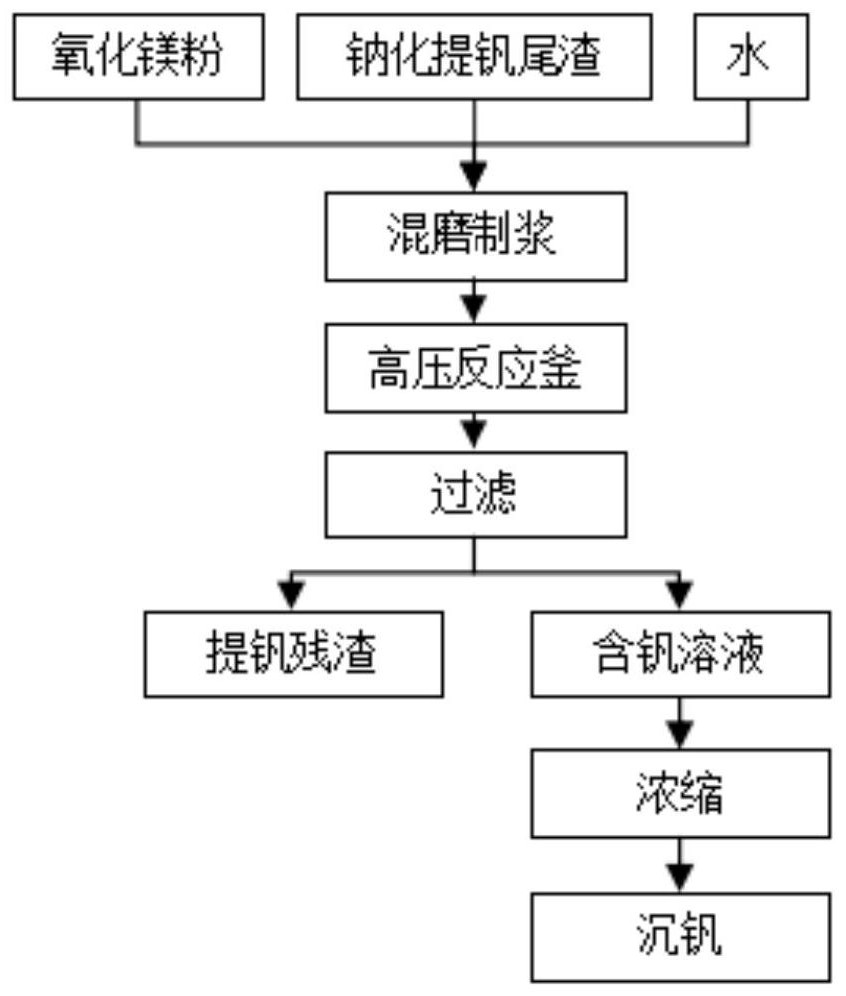

Image

Examples

Embodiment 1

[0067] Add 5% by weight of magnesium oxide powder and 0.5% by weight of sodium hexametaphosphate to the tailings of sodium vanadium extraction, then add industrial water according to the volume ratio of 6:1 according to the liquid-solid ratio, and ball mill for 45min in a ball mill to make the oxidized Magnesium, leaching aid and sodium vanadium extraction tailings are fully mixed evenly to form a homogeneous slurry, wherein the particle size of the sodium vanadium extraction tailings is below 0.2mm, and the purity of the magnesium oxide powder is 95% Above, the particle size of the magnesium oxide powder is below 0.074mm; the above slurry is put into a high-pressure reactor, and the hydrothermal reaction is carried out at 200°C, and the reaction time is 30min; the reacted slurry is filtered to obtain Vanadium solution and vanadium extraction residue. It is measured that the leaching rate of vanadium in the tailings of sodium vanadium extraction is as high as 62%.

Embodiment 2

[0069] Add 10% by weight of magnesium oxide powder and 0.2% by weight of sodium hexametaphosphate to the tailings for sodium vanadium extraction, then add industrial water according to the volume ratio of 8:1 according to the liquid-solid ratio, and ball mill for 30 minutes in a ball mill to make the oxidized Magnesium, leaching aid and sodium vanadium extraction tailings are fully mixed evenly to form a homogeneous slurry, wherein the particle size of the sodium vanadium extraction tailings is below 0.15mm, and the purity of the magnesium oxide powder is 98% Above, the particle size of the magnesium oxide powder is below 0.05mm; the above slurry is put into a high-pressure reactor, and a hydrothermal reaction is carried out at 120°C, and the reaction time is 60min; the reacted slurry is filtered to obtain Vanadium solution and vanadium extraction residue. It is measured that the leaching rate of vanadium in the tailings of sodium vanadium extraction is as high as 69%.

Embodiment 3

[0071] Add 8% by weight of magnesium hydroxide fine powder in the tailings of vanadium extraction by sodium, then add industrial water according to the volume ratio of 2:1 according to the liquid-solid ratio, and ball mill for 60min in a ball mill to make the magnesium hydroxide fine powder and sodium The vanadium extraction tailings are fully mixed uniformly to form a homogeneous slurry, wherein the particle size of the sodium vanadium extraction tailings is below 0.2mm, the purity of the magnesium hydroxide fine powder is above 95%, and the The particle size of the magnesium fine powder is below 0.074mm; the above slurry is put into a high-pressure reactor, and the hydrothermal reaction is carried out at 60°C, and the reaction time is 180min; the reacted slurry is filtered to obtain a vanadium-containing solution and extract Vanadium residue. It is measured that the leaching rate of vanadium in the tailings of sodium vanadium extraction is as high as 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com