A method for improving the performance of organic chrome-free tanned leather

A chrome-free tanning and performance technology, applied in the field of leather processing, can solve the problems of poor color fastness and physical sensory properties, lower shrinkage temperature of raw leather, unsatisfactory absorption and bonding of dyeing and finishing materials, etc. The effect of reducing usage and improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

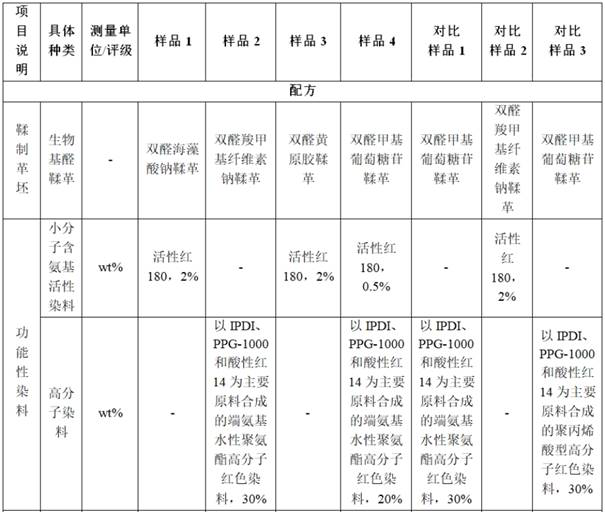

Examples

Embodiment 1

[0034] This embodiment is used to illustrate the overall steps of the manufacturing method of high-performance leather, specifically including:

[0035] After the bio-based aldehyde tanned leather is shaved and remoisturized, conventional retanning agents, bio-based amino resin retanning agents, functional dyes and fatliquoring agents are added for reaction; specifically: the bio-based aldehyde tanned leather is squeezed, Shave to obtain smooth leather, and weigh it as the material standard for subsequent materials; first, rehydrate according to the conventional process, then put the rewetted shaved leather into the drum, add water 100% of the weight of the shaved leather, Keep the temperature inside the drum at 35°C, add 3%~10% of conventional retanning agent, 1%~3% of bio-based amino resin retanning agent and 2%~30% of For functional dyes, the total rotation time is 2.5~3.5 hours, then add formic acid with 1.0%~1.5% of the weight of the smoothed leather into the drum, add in...

Embodiment 2-9

[0039] Embodiment 2-9: to illustrate the specific manufacturing method of high-performance leather:

Embodiment 2

[0041] A method for improving the properties of organic chrome-free tanned leather:

[0042] (1) Squeeze and shave the dialdehyde methyl glucoside tanned leather to obtain a shaved leather, and weigh it as the material standard for subsequent materials; first, rewet according to the conventional process, and then rewet the shaved leather Put the leather into the drum, add water with 100% of the weight of the shaved leather, keep the temperature in the drum at 35°C, add macromolecular acrylic resin retanning agent A33 of 1% of the weight of the shaved leather, and 2% of Small and medium molecule acrylic resin retanning agent RF15, 3% protein filler TJ-950, 1% dialdehyde sodium alginate-melamine resin retanning agent, 4% wattle extract TJ-R228 and 2% reactive red 180, the total rotation time is 2.5 hours, then add formic acid with a weight of 1.0%~1.5% of the shaved leather into the drum, add in portions, adjust the pH of the bath solution to 4.0~4.2, and then continue to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com