Combined electrolytic machining tool cathode and method for improving flatness of machined bottom surface

A technology for machining tools and tool cathodes, which is used in machining electrodes, electrode manufacturing, electric machining equipment, etc., and can solve the problems that the radial size of the rectangular electrode cannot be further reduced, the diameter of the tube electrode is small, and the localization is reduced. Inhibits stray corrosion and overcutting, improves process economy, and results in quick and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

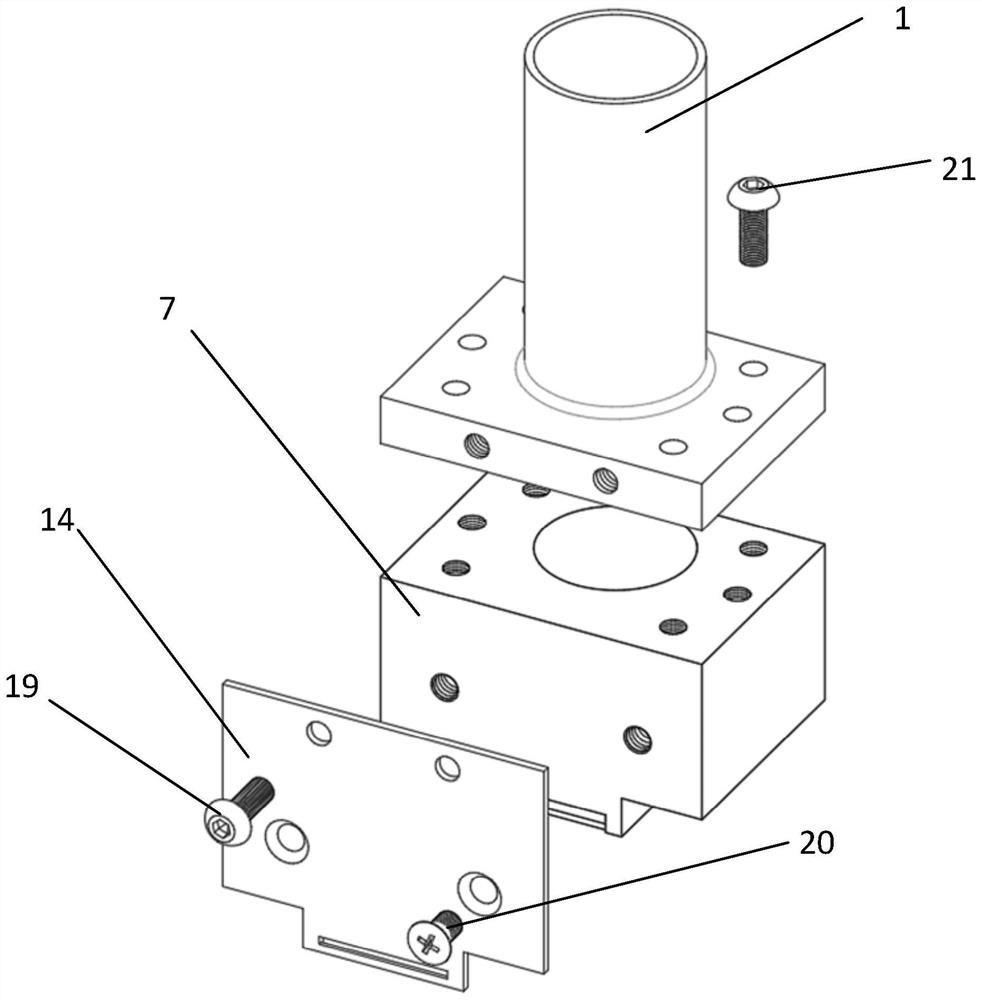

[0037] like Figure 7 As shown, for blocky workpiece 25:

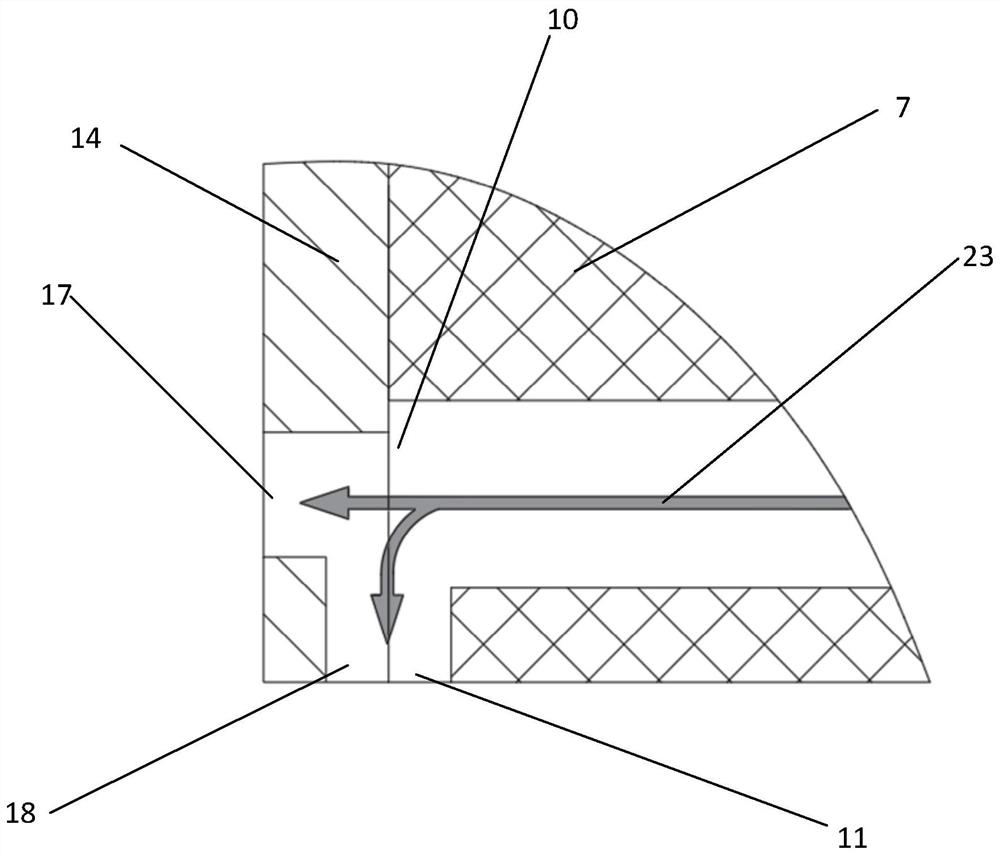

[0038] Step 1: Clamp the tool handle 1 vertically on the spindle of the machine tool, connect the negative pole of the power supply 24 to the cathode of the tool, and connect the positive pole of the power supply 24 to the workpiece, and the liquid outlet 17 on the side of the conductive plate is facing the massive workpiece 25. The cutting depth of the tool cathode is the outlet on the side of the conductive plate Within the range of 1-2 times the distance from the top of the liquid port 17 to the bottom of the conductive plate 14;

[0039] Step 2: Turn on the switch of the electrolyte 23, the electrolyte 23 flows into the central blind hole 13 of the insulating block 7 along the central through hole 3 of the handle 1, and finally flows to the processing gap along the liquid outlet 17 on the side of the conductive plate and the liquid outlet on the bottom surface of the tool cathode ;

[0040] Step 3: During process...

Embodiment 2

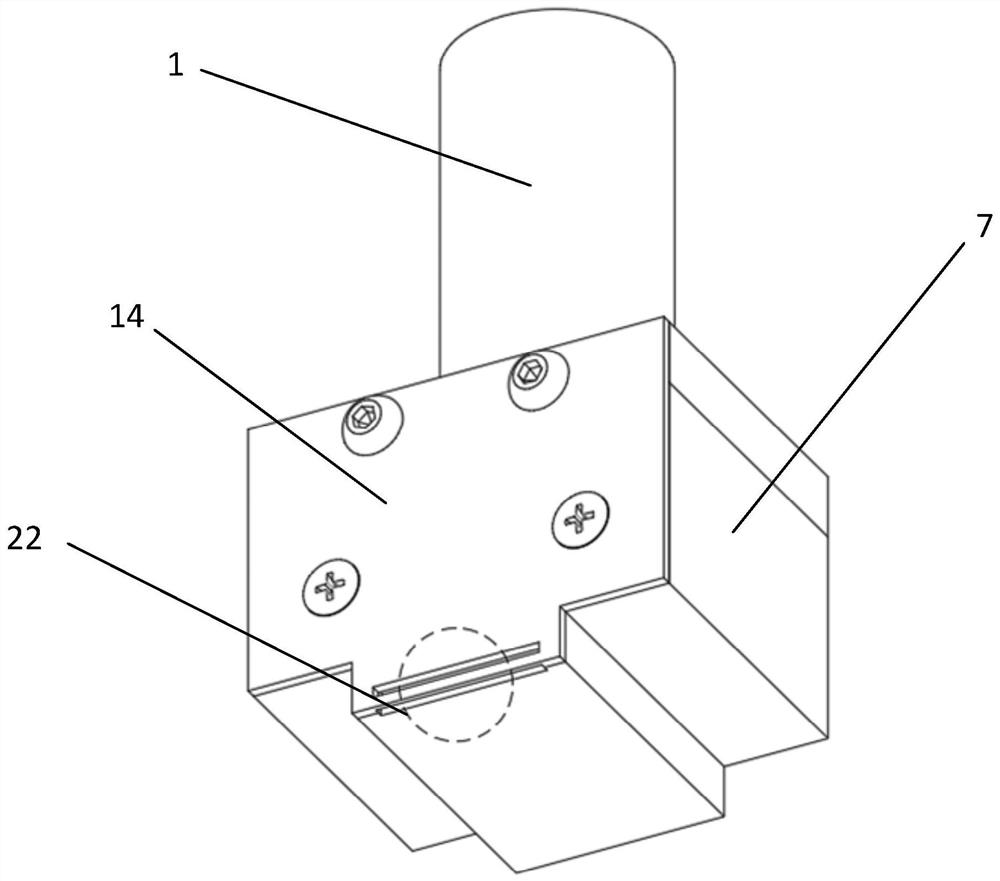

[0042] like Figure 8 As shown, for the shaft workpiece 27:

[0043] Step 1: Clamp the tool holder 1 vertically on the spindle of the machine tool, connect the negative pole of the power supply 24 to the cathode of the tool, and connect the positive pole of the power supply 24 to the workpiece, and the liquid outlet 17 on the bottom of the conductive plate is facing the side of the shaft workpiece 27;

[0044] Step 2: keep the shaft workpiece 27 still, cut the tool cathode radially along the shaft workpiece 27, and the processing depth is within 1-2 times of the distance from the top of the liquid outlet 17 on the side of the conductive plate to the bottom of the conductive plate 14;

[0045] Step 3: keep the cathode of the tool still, the shaft workpiece 27 rotates along the rotation direction 28 of the shaft workpiece, and the electrolyte 23 flowing out from the liquid outlet 17 on the side of the conductive plate and the liquid outlet on the bottom surface of the tool catho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com