Manufacturing method of roll-bond aluminum vapor chamber

A production method and a technology of a uniform temperature plate, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, and electrical equipment structural parts, etc., can solve the problems of inability to meet the heat dissipation requirements of base stations and poor heat dissipation efficiency, and achieve improved production efficiency and good quality. efficiency, overcome difficulties, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

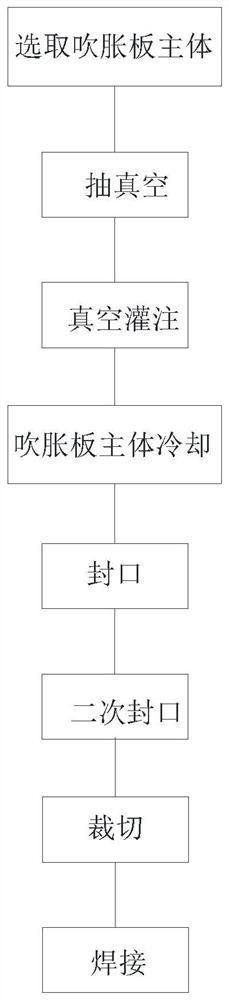

[0024] figure 1 A schematic flow diagram schematically showing a method for manufacturing an inflated aluminum vapor chamber according to an embodiment of the present invention. The specific steps are as follows:

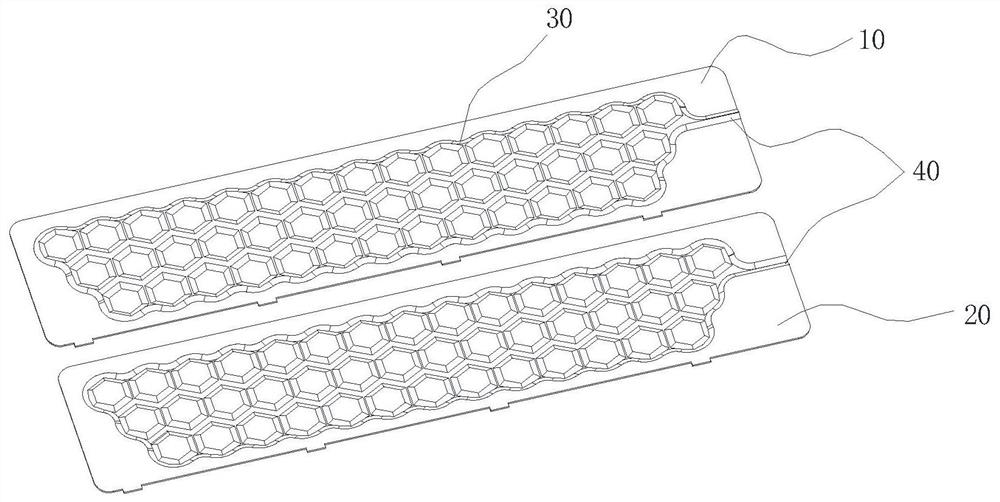

[0025] S1. Select the main body of the aluminum inflation plate. The main body of the inflation plate includes a heat sink 1 and an inlet 40 . Wherein the heat sink 1 is formed by corresponding covering of the upper cover plate 10 and the lower cover plate 20, the edges of the upper cover plate 10 and the lower cover plate 20 are welded and sealed to form the main structure of the heat sink 1, the upper cover plate 10, the lower cover plate 20 jointly define a flow channel 30 ; the inlet 40 corresponds to one end of the heat sink 1 and communicates with the flow channel 30 . The thickness of the upper cover plate 10 and the lower cover plate 20 is no more than 1.5 mm, and the thickness of the main body of the inflation plate is 5 mm. The structure of the main body...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is:

[0033] The main body of the expansion plate is made of aluminum alloy, which is hard and easy to process, which can ensure the product quality of the aluminum vapor chamber;

[0034] The thickness of the main body of the inflation plate is 4.5 mm, and the thickness of the upper cover plate 10 and the lower cover plate 20 is not more than 1.2 mm;

[0035] The working fluid is Honeywell 1233ZD, a fluorinated liquid, which is gaseous at normal temperature and pressure, and has a boiling point of 18°C. In step 3, the tank body does not need to be heated, and the working fluid can be perfused; Cool the main body of the blown plate to below 15°C to ensure that the Honeywell 1233ZD is fully liquefied. During this process, the range of temperature change is small, which can reduce energy consumption. In addition, the working medium can be replaced by fluorinated liquids such as R134A, R22, 3M 7100, etc. Similar to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com