Low-temperature high-power lithium-manganese battery and preparation method thereof

A lithium-manganese battery, high-power technology, applied in primary batteries, electrodes of primary batteries, dry batteries, etc., can solve the problem of reducing the mobility of LI+ in the electrolyte, low self-discharge rate, affecting battery ionic conductivity and idea transfer rate. and other problems, to achieve the effect of improving high-rate discharge performance, improving electronic conductivity, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A preparation method of the low-temperature high-power lithium-manganese battery specifically comprises the following steps:

[0057] S1. Preparation of graphene-based manganese dioxide cathode sheet

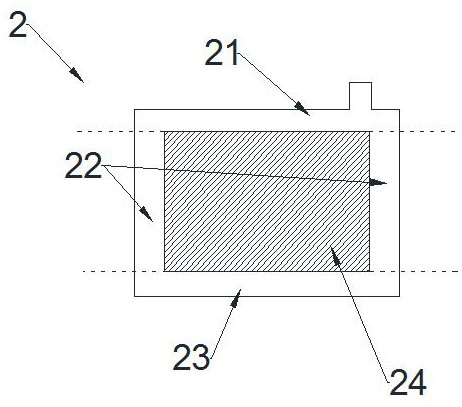

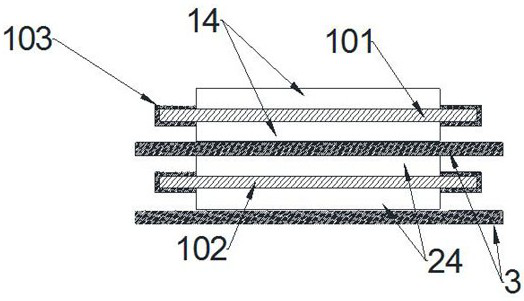

[0058] 85% to 98% by mass of graphene-based manganese dioxide, 1% to 10% of conductive agent, and 1% to 15% of binder are made into positive electrode slurry and evenly coated on the current collector by a coating machine The front and back of the aluminum mesh 101, the positive electrode slurry forms the positive electrode coating 14 on the front and back of the current collector aluminum mesh 101, and the four sides of the positive electrode coating 14 are respectively pre-coated with the four edges of the current collector aluminum mesh 101. There is a positive blank area, and the positive blank area is divided into the reserved tab 11 for the positive electrode, the positive high molecular glue area 13, and two positive insulating tape areas 12. The reserved tab 11 fo...

Embodiment

[0074] Such as Figure 5 As shown, compared to the traditional lithium-manganese battery, under the low temperature environment of -40 ° C, when the discharge current of the traditional lithium-manganese battery and the lithium-manganese battery prepared in the present invention are the same as 3C, the lithium-manganese battery provided by the present invention On the discharge voltage platform, the battery capacity retention rate of the manganese battery is significantly higher than that of the traditional lithium-manganese battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com