A kind of preparation method of composite structure of copper-aluminum transition section

A composite structure, copper-aluminum composite technology, used in additive manufacturing, additive processing, etc., can solve the problems of laser reflectivity and thermal conductivity, metallurgical defects, weak bonding strength, oxidation, etc., to save material costs and labor. effect of time, reduced risk of breakage, high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

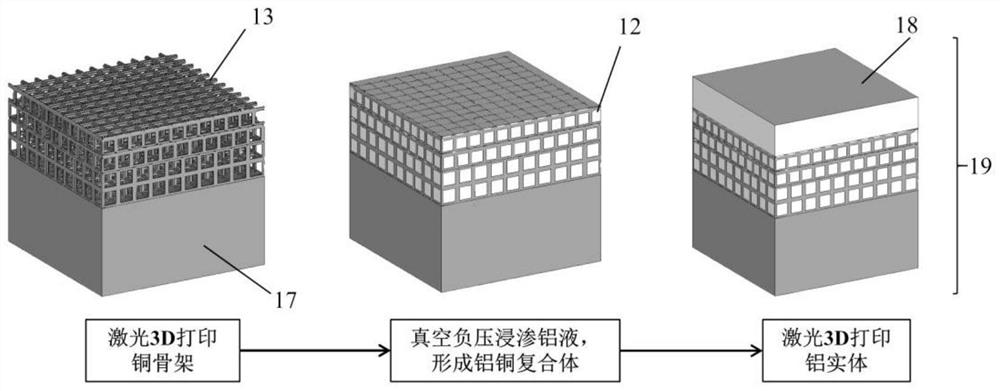

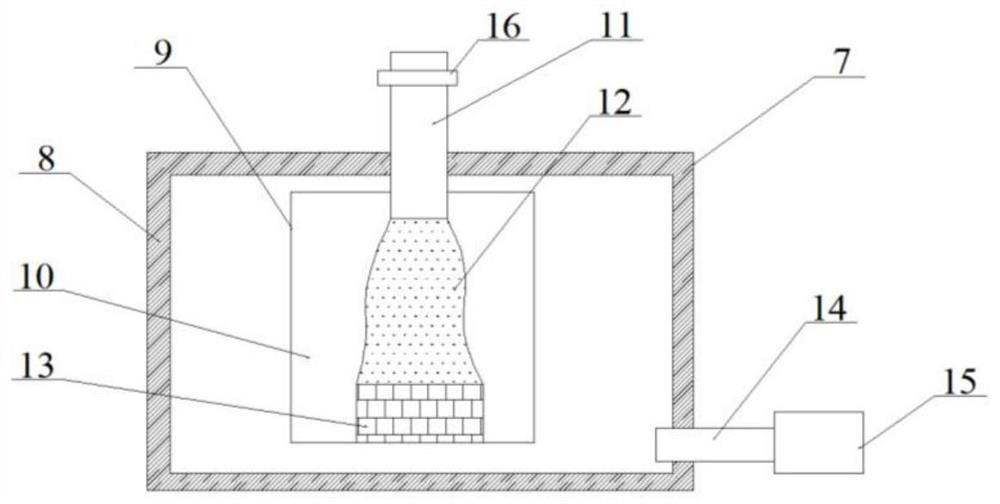

[0016] Such as figure 1 As shown, the method for preparing a copper-aluminum transition section composite structure using 3D printing technology includes the following steps:

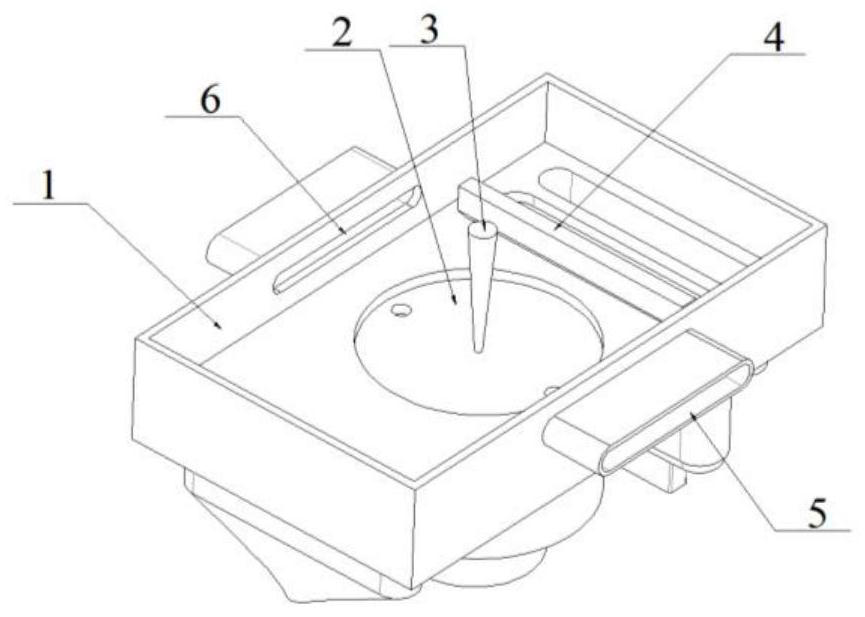

[0017] (1) Laser 3D printing copper skeleton 13: 3D printing equipment such as image 3 As shown, taking the copper entity 17 on the forming substrate as the reference plane, using the spherical oxygen-free copper powder as the raw material, using the built-in powder feeding box and the scraper 4 to transport the oxygen-free copper powder, and evenly spreading the powder on the upper surface of the copper entity 17, The copper entity 17 is printed and formed on the partition, and the partition and the formed substrate 2 are connected and fixed through the positioning holes. The three-hole positioning method is adopted for the fixation. The copper skeleton 13 model is designed by using layered software, and the three-dimensional information is discretized to obtain each The two-dimensional plane and pro...

Embodiment 2

[0021] (1) Laser 3D printing copper skeleton 13: take the copper entity 17 on the forming substrate as the reference plane, use spherical copper-tin alloy powder as the raw material, use the built-in powder feeding box and scraper 4 to convey the copper-tin alloy powder, and spread the powder evenly On the upper surface of the copper entity 17, the copper entity 17 is printed and formed on the partition, and the partition and the formed substrate 2 are connected and fixed through the positioning holes. The three-hole positioning method is used for fixing, and the copper skeleton 13 model is designed by using layered software, and the The three-dimensional information is discretized, and the two-dimensional plane and profile information of each layer section is obtained, which is imported into the forming equipment 1. The argon inert gas is introduced into the forming equipment 1 from the air inlet 5, and is exported from the exhaust port 6 and filled in a cycle. Control the oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com