Lightweight fiber/ceramic-based composite bulletproof structure

A ceramic-based composite and lightweight technology, which is applied to the structure of armor plates, protective equipment, armor, etc., can solve the problem of high structural thickness, achieve the effects of reducing projectile speed, avoiding interlayer shedding, and preventing back convexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further description will be given below by means of drawings and embodiments.

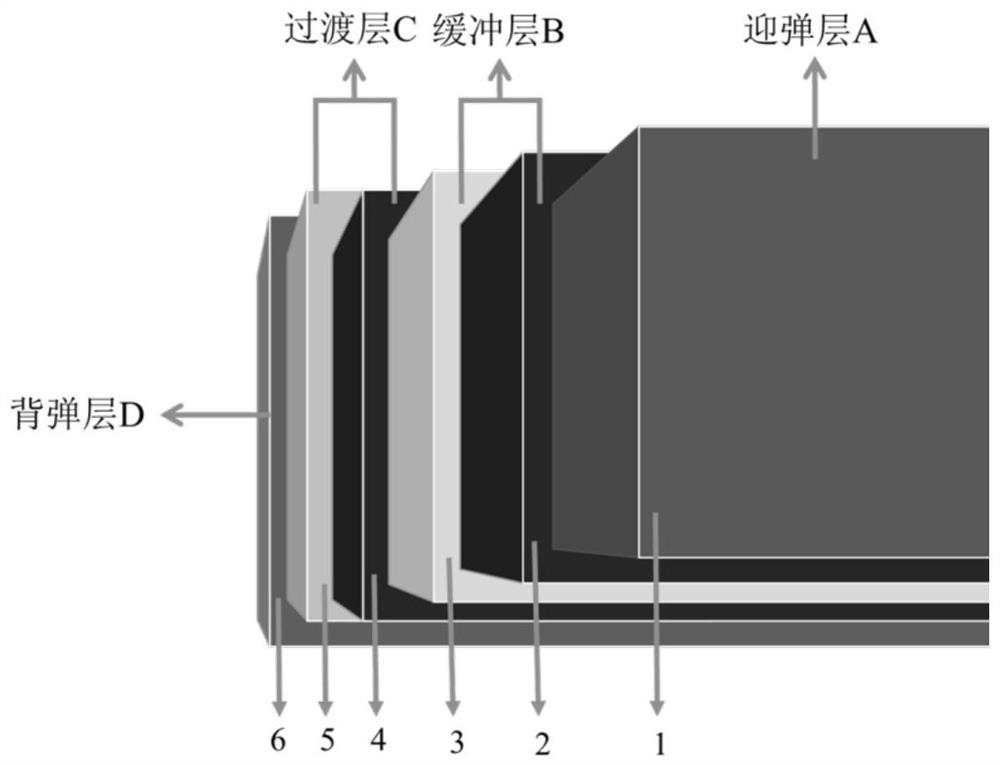

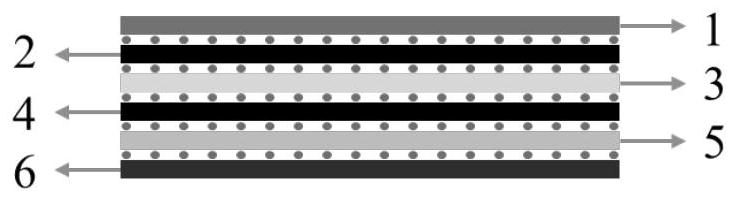

[0024] Such as figure 1 , 2 As shown, the lightweight fiber / ceramic matrix composite bulletproof structure of the present invention includes a bulletproof layer A, a buffer layer B, a transition layer C and a back bulletproof layer D; the bulletproof layer A is arranged on the lightweight fiber / ceramic matrix composite bulletproof structure The outermost side, the back elastic layer D is set on the innermost side of the lightweight fiber / ceramic matrix composite bulletproof structure, wherein, the anti-bullet layer A is alternately stacked with high-performance carbon fiber cloth 1 structural layers, and the back elastic layer D is hard aramid fiber Plate 6; the buffer layer B and the transition layer C are arranged between the bombardment layer A and the backball layer D, wherein the buffer layer B is arranged on the lower side of the bombardment layer A, which is a single-layer boron carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com