A magnesium-containing biological beta titanium alloy with micro/nano pores and preparation method thereof

A β-titanium alloy and nanoporous technology, applied in prosthetics, medical science, etc., can solve the problems of no obvious ability to induce bone formation, slow tissue integration, etc., and achieve the application range of large components, increased porosity, and high yield strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

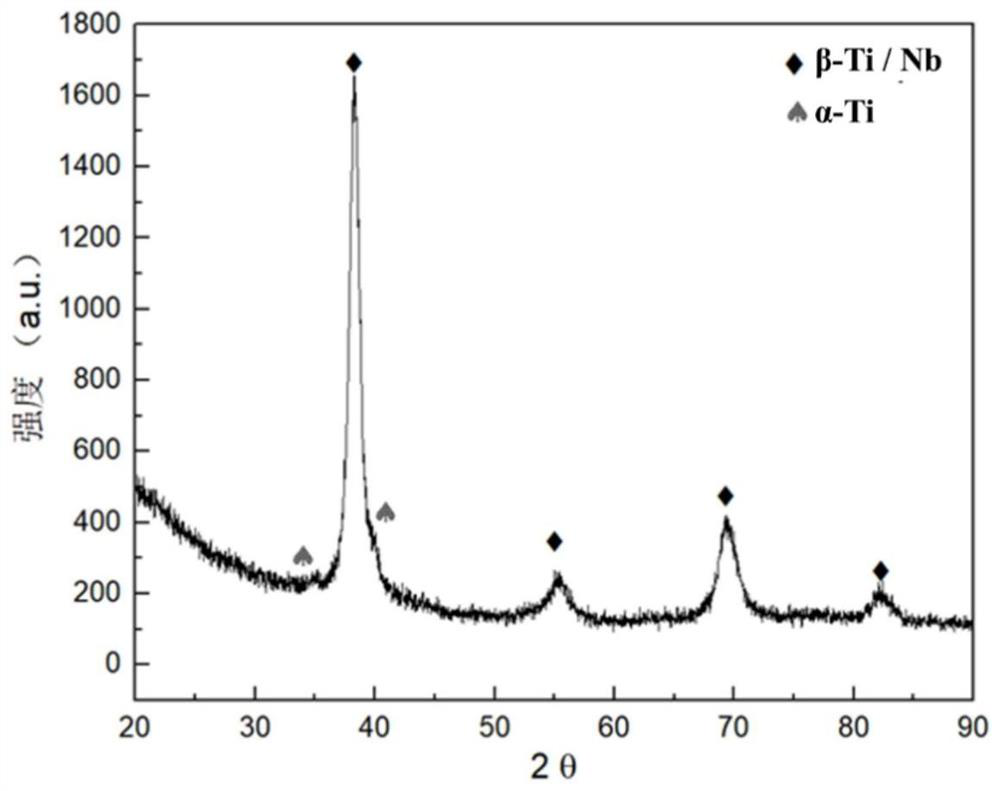

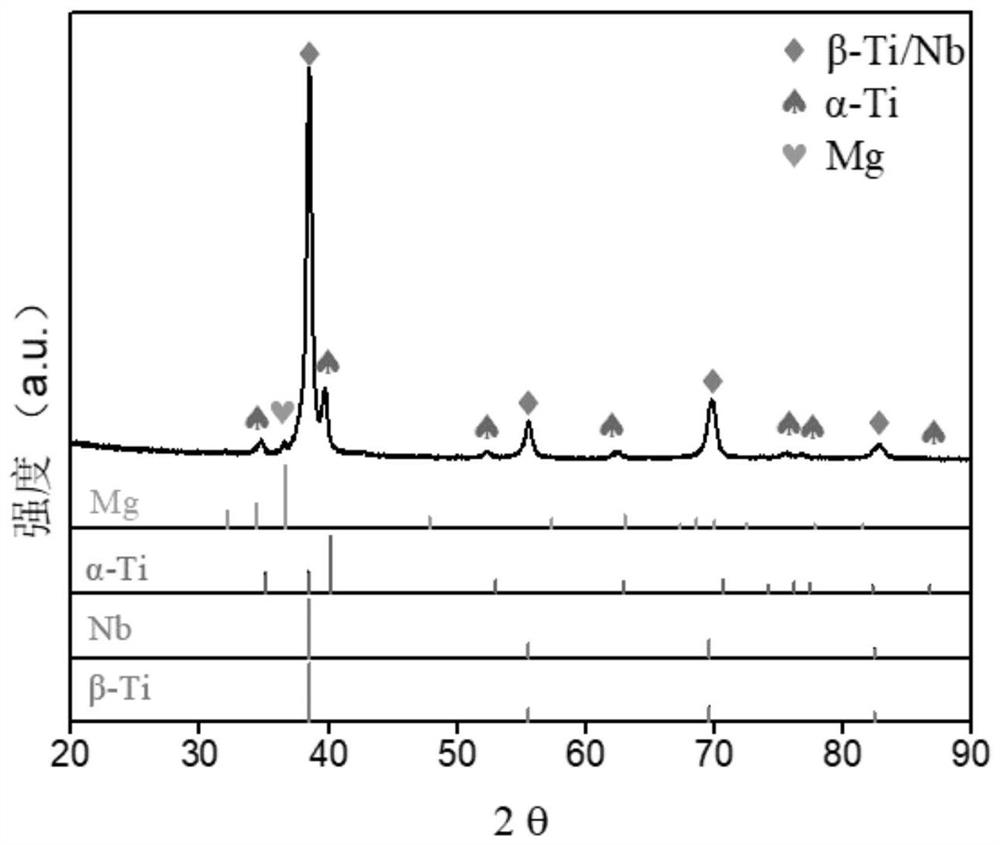

[0033] This embodiment provides a magnesium-containing biological β-titanium alloy with micro / nano pores, which comprises the following components in terms of mass percentage: 5% of pure magnesium powder and 95% of biological β-titanium alloy powder; The β-titanium alloy powder includes pure titanium powder and pure niobium powder, the pure titanium powder accounts for 60% of the total mass percentage of the magnesium-containing biological β-titanium alloy, and the pure niobium powder accounts for 35% of the total mass percentage of the magnesium-containing biological β-titanium alloy.

[0034] The above biological β-titanium alloy powder can also include but not limited to any pre-alloyed powder in titanium-niobium alloy powder, titanium-tantalum alloy powder, titanium-molybdenum alloy powder or titanium-niobium-zirconium alloy powder; or titanium, niobium, molybdenum and The zirconium metal powder is obtained according to the alloy composition ratio to obtain titanium-niobium...

Embodiment 2

[0042] The present embodiment provides a magnesium-containing biological β-titanium alloy with micro / nano pores, which comprises the following components in terms of mass percentage: 3% pure magnesium powder and biological β-titanium-molybdenum alloy powder (Ti-15Mo, mass score) 97%.

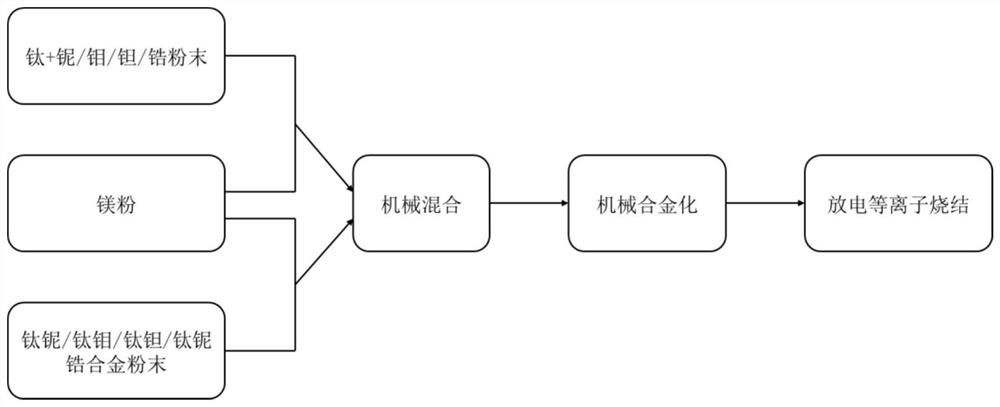

[0043] The above-mentioned magnesium-containing biological titanium-niobium alloy with micro / nano pores can be prepared by the following method, referring to figure 1shown, including the following steps:

[0044] Take 200-300-mesh pure magnesium powder and 200-300-mesh Ti-15Mo alloy powder, and mix according to the above mass percentages. The total mass of pure magnesium powder and titanium-molybdenum alloy powder was weighed to be 50g.

[0045] The pure magnesium powder and the titanium-molybdenum alloy powder are mechanically mixed by a planetary ball mill to form a mixed powder. The following ball milling process parameters are adopted: the ball-material ratio is 10:1, the ball milling spee...

Embodiment 3

[0049] This embodiment provides a magnesium-containing bio-titanium-niobium alloy with micro / nano pores, which comprises the following components in terms of mass percentage: 7% of pure magnesium powder and 93% of biological β-titanium, niobium and zirconium powder matrix.

[0050] The above-mentioned magnesium-containing biological β-titanium alloy with micro / nano pores can be prepared by the following method, referring to figure 1 shown, including the following steps:

[0051] Take 200-300-mesh pure magnesium powder, 100-200-mesh titanium-niobium-zirconium alloy powder, and mix according to the above mass percentages.

[0052] The pure magnesium powder and the titanium, niobium and zirconium alloy powder are mechanically mixed by a planetary ball mill to form a mixed powder. The following ball milling process parameters are adopted: the ball-to-material ratio is 20:1, the ball milling speed is 200rpm, and the ball milling time is 5h.

[0053] A planetary ball mill is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com