A kind of water-soluble sponge with density gradient and preparation method and application thereof

A density gradient, water-soluble technology, applied in applications, medical formulations, surgery, etc., can solve the problems of high foam density, complicated preparation process, and difficult use of medical hemostatic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

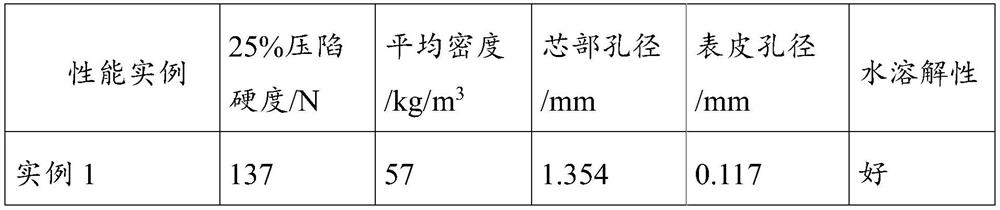

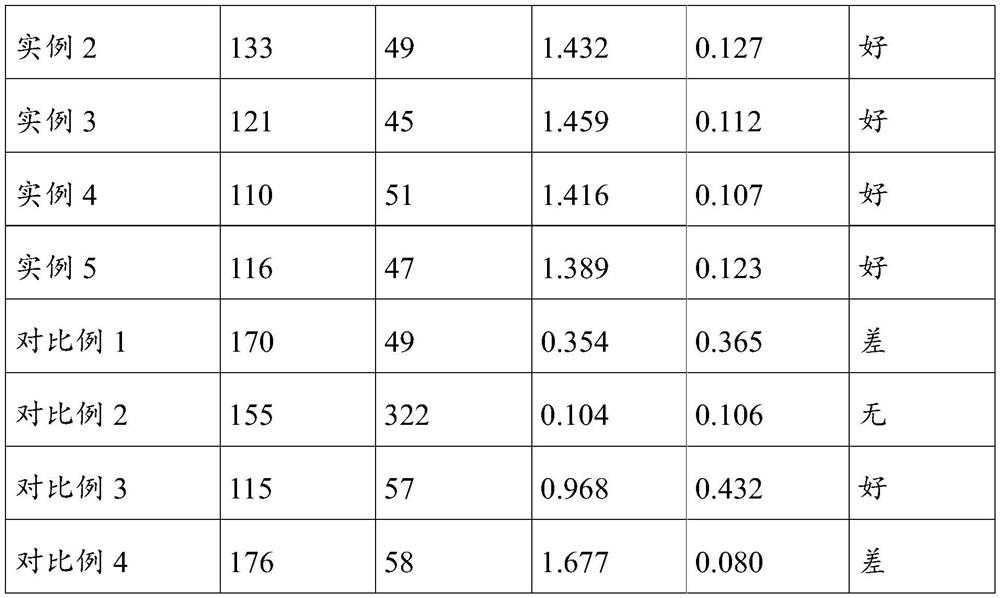

Examples

Embodiment 1

[0043] (1) 200 ml of a dispersion liquid containing 7% polyvinyl alcohol 1788 and 3% hydroxyethyl methyl cellulose was prepared. First, polyvinyl alcohol 1788 and hydroxyethyl methyl cellulose were added to deionized water containing 2% ethanol to swell for 24 hours, and then stirred for 6 hours at 60 °C under vacuum conditions of -0.095 MPa to obtain uniform dispersion A.

[0044] (2) Add 2% thickener AH-1509 to 50ml of water-based polyurethane AH-1618, and stir for 2 hours at room temperature under -0.095MPa vacuum to obtain uniform dispersion B.

[0045](3) Mix 200ml A and 50ml B, stir evenly at room temperature under -0.095MPa vacuum condition, then pour into a centrifuge tube and centrifuge at 10000r / min for 60s.

[0046] (4) Freeze the centrifuge tube containing the sample in step (3) at -25°C for 12h.

[0047] (5) Take out the thoroughly frozen sample, freeze-dry it at -80°C for 24 hours, and obtain a water-soluble sponge with a density gradient.

Embodiment 2

[0049] (1) 200 ml of an aqueous dispersion containing 10% of polyvinyl alcohol 1788 was prepared. First, polyvinyl alcohol 1788 was added to deionized water containing 2% ethanol to swell for 24 hours, and then stirred for 6 hours at 60°C under -0.095MPa vacuum to obtain uniform dispersion A.

[0050] (2) Add 2% thickener AH-1509 to 50ml of water-based polyurethane AH-1618, and stir for 2 hours at room temperature under -0.095MPa vacuum to obtain uniform dispersion B.

[0051] (3) Mix 200ml of dispersion A and 50ml of dispersion B, stir evenly at room temperature under -0.095MPa vacuum condition, then pour into a centrifuge tube and centrifuge at 12000r / min for 60s.

[0052] (4) Freeze the centrifuge tube containing the sample in step (3) at -25°C for 12h.

[0053] (5) Take out the thoroughly frozen sample, freeze-dry it at -80°C for 24 hours, and obtain a water-soluble sponge with a density gradient.

Embodiment 3

[0055] (1) 250 ml of an aqueous dispersion containing 10% of polyvinyl alcohol 1788 was prepared. First, polyvinyl alcohol 1788 was added to deionized water containing 2% ethanol to swell for 24 hours, and then stirred for 6 hours at 60°C under -0.095MPa vacuum to obtain uniform dispersion A.

[0056] (2) Add 2% thickener AH-1509 to 50ml of water-based polyurethane AH-1618, and stir for 2 hours at room temperature under -0.095MPa vacuum to obtain uniform dispersion B.

[0057] (3) Mix 250ml of dispersion A and 50ml of dispersion B, stir evenly at room temperature under -0.095MPa vacuum condition, then pour into a centrifuge tube and centrifuge at 6000r / min for 60s.

[0058] (4) Freeze the centrifuge tube containing the sample in step (3) at -25°C for 12h.

[0059] (5) Take out the thoroughly frozen sample, freeze-dry it at -80°C for 24 hours, and obtain a water-soluble sponge with a density gradient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com