Waterborne polyurethane dispersion and preparation method thereof

A technology of water-based polyurethane and polyurethane prepolymer, applied in the direction of coating, etc., can solve problems such as swelling of ribs, achieve the effect of improving drying speed, strengthening strength, and improving water sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] On the basis of the above-mentioned technical scheme, the embodiment of the present application also provides a kind of preparation method of aqueous polyurethane dispersion, comprises the following steps:

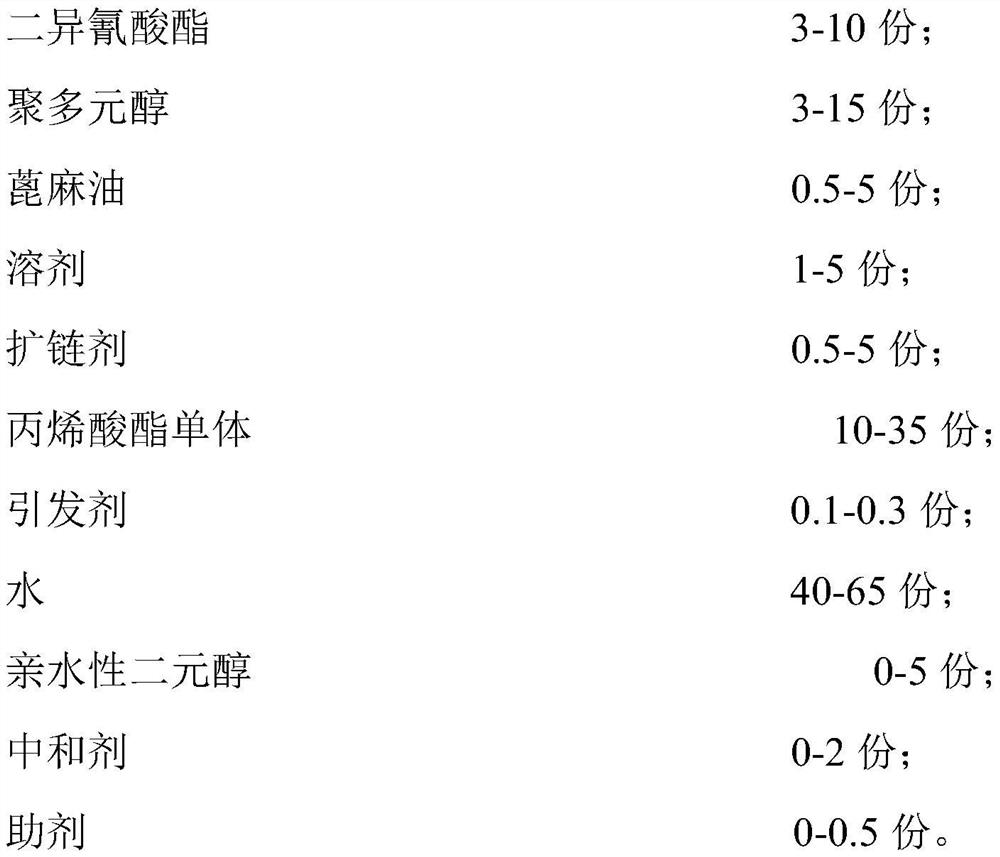

[0041] S01. According to the above-mentioned aqueous polyurethane dispersion, the raw materials for preparation are provided: diisocyanate, polypolyol, castor oil, solvent, chain extender, acrylate monomer, initiator, water, hydrophilic diol, neutralizer and auxiliary agent;

[0042] S02, mixing diisocyanate, polypolyol, castor oil, hydrophilic dibasic alcohol and a solvent to perform a first reaction to obtain a polyurethane prepolymer;

[0043] S03, mixing the polyurethane prepolymer, the acrylate monomer and the neutralizing agent to obtain a mixture;

[0044] S04, dispersing water in the mixture under high-speed stirring, then adding a chain extender and performing a second reaction to obtain an intermediate;

[0045] S05, mixing the intermediate and the initi...

Embodiment 1

[0065] Present embodiment provides a kind of aqueous polyurethane dispersion, and its preparation method comprises the following steps:

[0066](1) A 1000mL four-necked flask equipped with a stirring device and a thermometer was dehydrated and fed with nitrogen, and 46.4g of toluene diisocyanate, 60.6g of BG / AA type polyester diol with a molecular weight of 1000 after dehydration, 7.64g Castor oil, 12.73g dimethylol propionic acid, 30g DMF (polyurethane grade), start stirring, slowly raise the temperature to 60°C, heat up to 75°C for 3-4h, the NCO test value in the system is less than 6.1 of the theoretical value %;

[0067] (2) Cool down to 50°C, add 254g methyl methacrylate and stir for 30 minutes, then add 9.8g triethylamine and carry out neutralization reaction for 15 minutes to obtain the mixture; after that, transfer the mixture to the dispersion bucket, and Quickly add the prepared 640g deionized water under the high-speed stirring state with a speed greater than 1000r...

Embodiment 2

[0070] Present embodiment provides a kind of aqueous polyurethane dispersion, and its preparation method comprises the following steps:

[0071] (1) A 1000mL four-necked flask equipped with a stirring device and a thermometer was dehydrated and fed with nitrogen, and 59.2g of isophorone diisocyanate, 47.7g of dehydrated polycarbonate diol with a molecular weight of 1000, 8.56g Castor oil, 14.27g dimethylolpropionic acid, 25g PMA (polyurethane grade), start stirring, slowly raise the temperature to 70°C, heat up to 85°C for 3-4h, the NCO test value in the system is less than 5.0 of the theoretical value %;

[0072] (2) Cool down to 50°C, add 291g methyl methacrylate and 33g isobornyl methacrylate and stir for 30 minutes, then add 11.4g triethylamine and carry out neutralization reaction for 15 minutes to obtain a mixture; after that, the mixture Transfer to the dispersion bucket, and quickly add the prepared 590g of deionized water under the high-speed stirring state of greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com