Ternary composite electrode material for hybrid capacitor and application of material

A hybrid capacitor and ternary composite technology, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nickel compounds, etc. Improve the specific capacity, improve the conductivity, the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

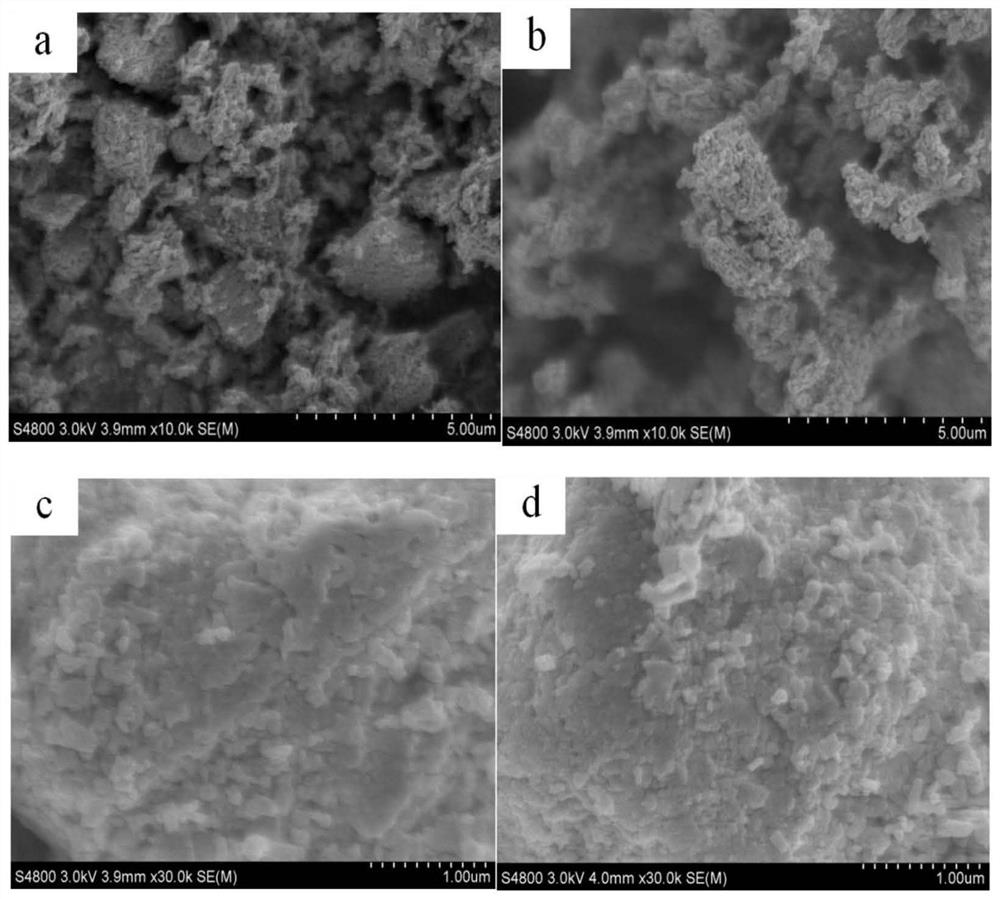

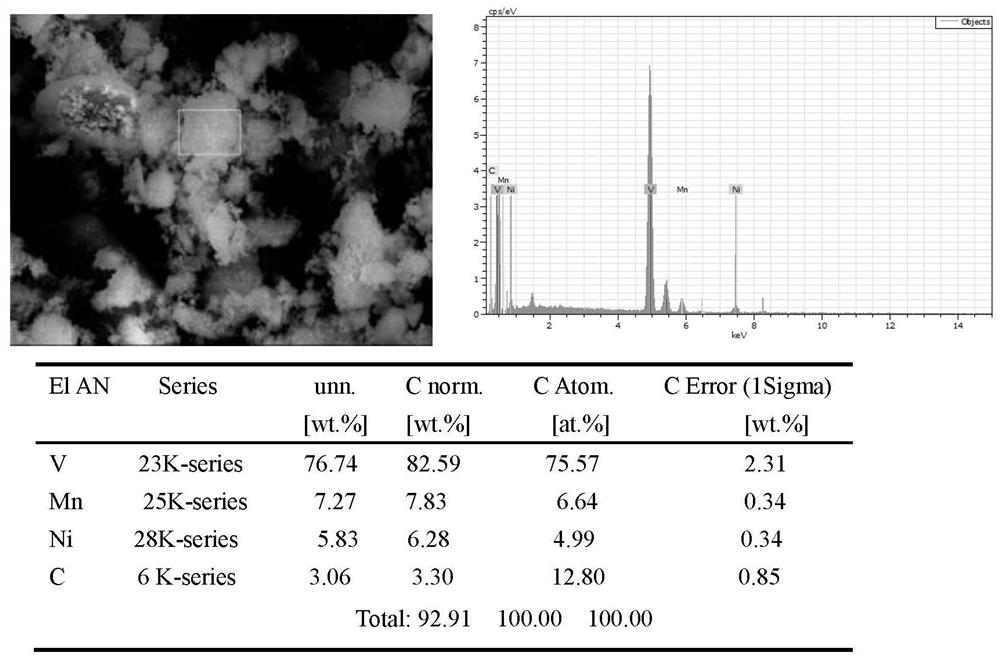

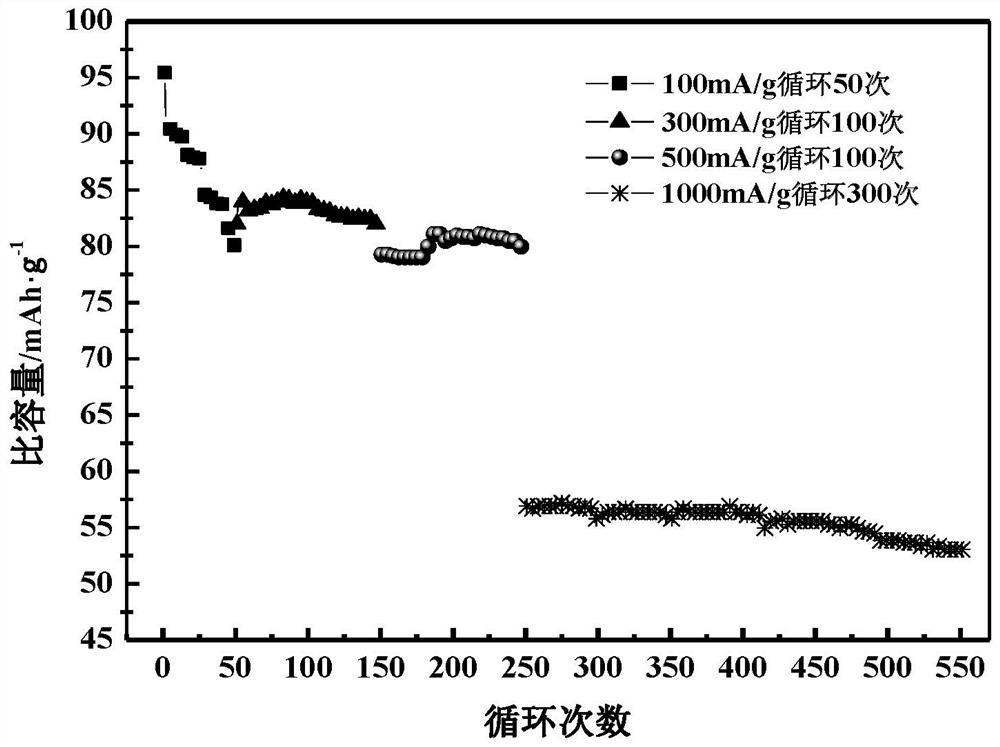

Embodiment 1

[0034]According to ammonium metavanadate, nickel acetate, manganese acetate molar ratio is 8:0.5:0.5 and takes raw material; First add nickel acetate, manganese acetate in 450mL deionized water and be mixed with the acetic acid that nickel acetate and manganese acetate concentration are 0.02mol / L Nickel-manganese acetate mixed solution; then add sodium carbonate to prepare 0.2mol / L sodium carbonate solution in 450mL deionized water, and add 0.8mL of ammoniacal liquor with a mass concentration of 5%, and obtain sodium carbonate-ammonia mixed solution after mixing; Add the prepared sodium carbonate-ammonia water mixed solution dropwise into the nickel acetate-manganese acetate mixed solution through a peristaltic pump at a rate of 50mL / min, stir evenly and let it stand, discard the supernatant, and centrifuge to retain the precipitate; Put the precipitate obtained by centrifugation into a container, dry it at 100°C for 20 hours, add ammonium metavanadate and 5mL distilled water a...

Embodiment 2

[0039] According to ammonium metavanadate, nickel acetate, manganese acetate molar ratio is 8:0.25:0.25 and weighs raw material, first adds nickel acetate, manganese acetate in 450mL deionized water and is mixed with nickel acetate and manganese acetate concentration and is 0.04mol / L Nickel acetate-manganese acetate mixed solution; then add sodium carbonate to prepare 0.1mol / L sodium carbonate solution in 450mL deionized water and add 0.7mL ammonia water, mix well to obtain sodium carbonate-ammonia water mixed solution, then sodium carbonate-ammonia water mixed solution Add it all dropwise into 450mL of nickel acetate-manganese acetate mixed solution at a speed of 50mL / min through a peristaltic pump, stir evenly and let it stand, discard the supernatant, centrifuge, and retain the precipitate; put the precipitate obtained by centrifugation into Put it into the container, dry at 80°C for 20 hours, add ammonium metavanadate and 5mL distilled water after grinding; then put the mat...

Embodiment 3

[0043] According to the ammonium metavanadate, nickel acetate, manganese acetate molar ratio is 8:1:1, first add nickel acetate, manganese acetate in 450mL deionized water to prepare nickel acetate and manganese acetate concentration of 0.04mol / L acetic acid Nickel-manganese acetate mixed solution; then add sodium carbonate to prepare 0.2mol / L sodium carbonate solution in 450mL deionized water and add 0.5mL ammonia water, mix well to obtain sodium carbonate-ammonia water mixed solution, then sodium carbonate-ammonia water mixed solution passes Add the peristaltic pump dropwise into 450mL of nickel acetate-manganese acetate mixed solution at a speed of 50mL / min, stir evenly and let it stand, discard the supernatant, and centrifuge to keep the precipitate; put the precipitate obtained by centrifugation into Put it into a container, dry it at 120°C for 15 hours, add ammonium metavanadate and 5mL of distilled water after grinding; then put the material into an ultrasonic machine wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com