Ultraviolet LED packaging adhesive with high light extraction efficiency and light aging resistance and packaging structure

A technology of LED packaging and highlight extraction, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of not being able to withstand high-power ultraviolet radiation, short life, and short service life, and achieve long-term stable light aging resistance and prolong degradation and aging time, reducing the effect of total reflection light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

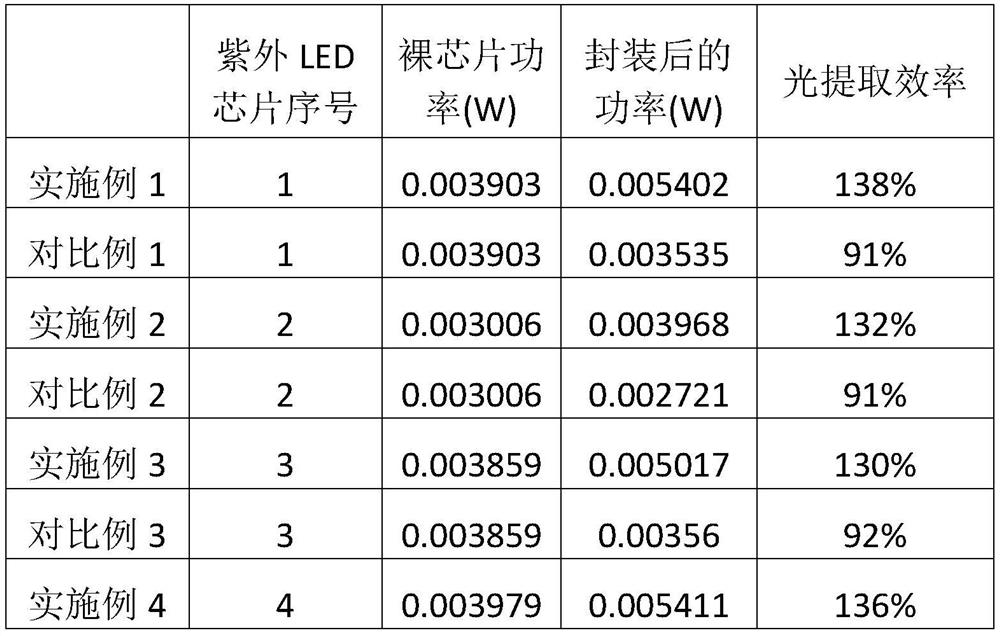

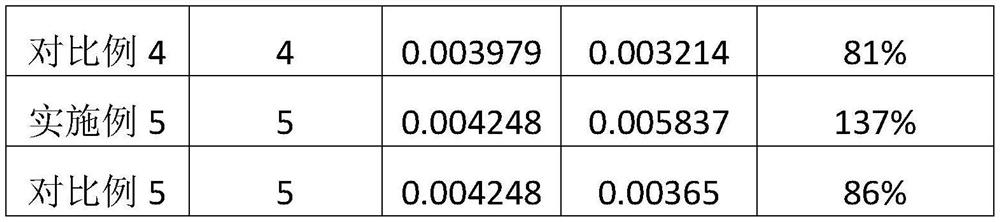

Embodiment 1

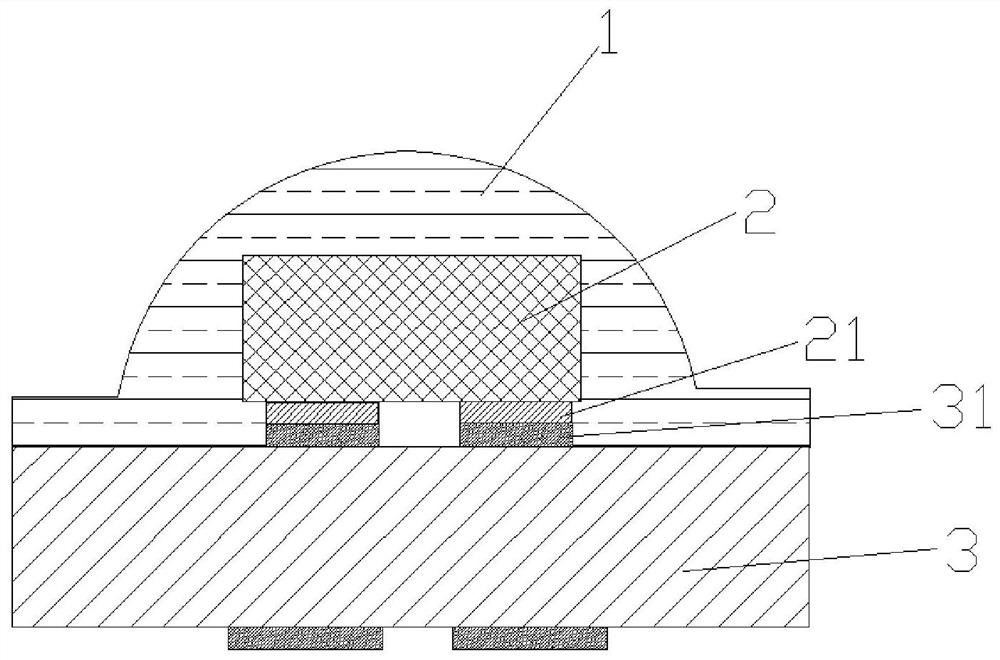

[0041] An ultraviolet LED packaging structure with high light extraction efficiency and long service life, comprising an ultraviolet LED chip 2 with a wavelength of 200-400nm, a packaging substrate 3 and an encapsulation adhesive layer 1 covering the ultraviolet LED chip 2, the positive side of the ultraviolet LED chip 2 The negative chip electrodes 21 are respectively connected to the two substrate electrodes 31 of the packaging substrate 3 .

[0042]The encapsulation adhesive of the encapsulation adhesive layer 1 contains colloids of Si-O, C-F, and Si-F bonds, a nickel light-stable quencher accounting for 0.1% of the colloid mass percent, and a dialkyl dialkyl group accounting for 3% of the colloid mass percent. Dithiocarbamate, 2,2-diphenyl-1-trinitrophenylhydrazine accounting for 5% of the colloid mass percentage, piperidine derivatives accounting for 10% of the colloid mass percentage, accounting for the colloid mass percentage 2% phosphate ester, 3% PEG400 in colloid mas...

Embodiment 2

[0044] An ultraviolet LED packaging structure with high light extraction efficiency and long service life, comprising an ultraviolet LED chip 2 with a wavelength of 200-400nm, a packaging substrate 3 and an encapsulation adhesive layer 1 covering the ultraviolet LED chip 2, the positive side of the ultraviolet LED chip 2 The negative chip electrodes 21 are respectively connected to the two substrate electrodes 31 of the packaging substrate 3 .

[0045] The encapsulating adhesive of the encapsulating adhesive layer 1 contains colloids of Si-O, C-F, and Si-F bonds, a nickel light-stable quencher accounting for 5% of the colloid mass percent, and a dialkyl dialkyl group accounting for 5% of the colloid mass percent. Phosphorodithioate, p-benzoquinone accounting for 7% of the colloid mass percent, piperazine derivatives accounting for 8 percent of the colloid mass percent, titanate accounting for 5 percent of the colloid mass percent, accounting for 3 percent of the colloid mass pe...

Embodiment 3

[0047] An ultraviolet LED packaging structure with high light extraction efficiency and long service life, comprising an ultraviolet LED chip 2 with a wavelength of 200-400nm, a packaging substrate 3 and an encapsulation adhesive layer 1 covering the ultraviolet LED chip 2, the positive side of the ultraviolet LED chip 2 The negative chip electrodes 21 are respectively connected to the two substrate electrodes 31 of the packaging substrate 3 .

[0048] The encapsulation adhesive of the encapsulation adhesive layer 1 contains colloids of Si-O, C-F, and Si-F bonds, a nickel light-stable quencher accounting for 10% by mass of the colloid, and a thiodisulfide accounting for 10% by mass of the colloid. Phenol esters, 2-methyl-2-nitrosomethane accounting for 15% of the colloid mass percent, piperidine derivatives accounting for 15 percent of the colloid mass percent, phosphate esters accounting for 5 percent of the colloid mass percent, accounting for colloid The mass percentage is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com