Method for inhibiting degradation of gamma-polyglutamic acid and gamma-polyglutamic acid water-retaining agent

A polyglutamic acid, degradation inhibitor technology, applied in chemical instruments and methods, agricultural machinery and implements, applications, etc., can solve problems such as reports that have not yet seen the degradation of γ-PGA and γ-PGA-based water-retaining agents, Achieve the effect of low cost, wide application prospect and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

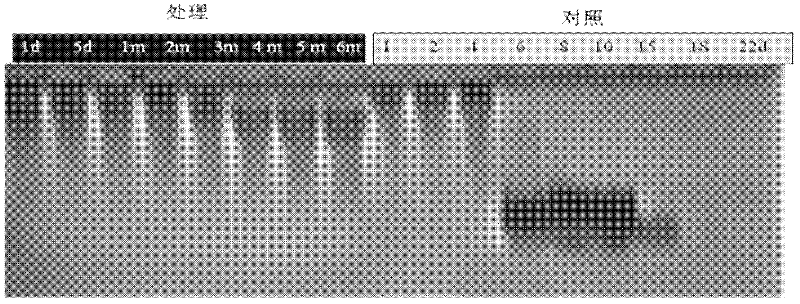

[0059] Example 1: Inhibitory effect of EDTA disodium salt on gamma-PGA degradation

[0060] The γ-PGA solution obtained by dissolving 2g of γ-PGA in 200ml of tap water was used as a control sample. γ-PGA in which 2% ethylenediaminetetraacetic acid disodium salt was added to γ-PGA was used as a test sample. A γ-PGA solution containing ethylenediaminetetraacetic acid disodium salt obtained by dissolving 2 g of a test sample in 200 ml of tap water was used as a test solution. The beakers containing the above two solutions were placed at room temperature (20-26° C.), and tap water was added therein every 5 days during the test to ensure that the volumes of the two solutions remained constant. At the same time, 1ml samples are regularly taken, the pH of these solution samples is the natural pH value, and these samples are stored at a temperature of -20°C to avoid further degradation by microorganisms, and these samples are analyzed at the same time, and the analysis method is as f...

Embodiment 2

[0064] Embodiment 2: the inhibitory effect of tartaric acid on gamma-PGA degradation

[0065] The γ-PGA solution obtained by dissolving 2g of γ-PGA in 200ml of tap water was used as a control sample. γ-PGA to which 2% of tartaric acid was added based on the weight of γ-PGA was used as a test sample. A γ-PGA solution containing tartaric acid obtained by dissolving 2 g of the test sample in 200 ml of tap water was used as a test solution. The beakers containing the above two solutions were placed at room temperature (20-26° C.), and tap water was added therein every 5 days during the test to ensure that the volumes of the two solutions remained constant. At the same time, 1ml samples are taken regularly, and the sampling time is from 0 days to 60 days. The pH of these solution samples is the natural pH value, and these samples are stored at a temperature of -20°C to avoid continued degradation by microorganisms. Sample is analyzed, and its analytical method is with embodiment ...

Embodiment 3

[0067] Example 3: Disodium ethylenediaminetetraacetic acid inhibits the degradation of γ-PGA-based water retaining agent

[0068] The preparation process of γ-PGA based water retaining agent is as follows:

[0069] γ-PGA, polypropylene glycol diglycidyl ether cross-linking agent and polyethylene glycol were dissolved in water to prepare 9.2% γ-PGA by weight, 4.6% polypropylene glycol diglycidyl ether cross-linking agent, 9.2% polyethylene glycol For the solution of diol, use hydrochloric acid as the reaction catalyst, and use hydrochloric acid to adjust the pH value of the reaction system to 5.0. The reaction system is reacted at a temperature of 60° C. for 36 hours, and the contents of the reaction system are pulverized into a paste with a pulverizer. Then dry it at a temperature of 50-55° C., and then crush it into 60-mesh particles, so as to obtain a gamma-PGA-based water-retaining agent.

[0070] Mix the prepared γ-PGA water-retaining agent dry powder with 2% ethylenediam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com