Capillary aluminum pipe for high-speed flowing of gallium-based liquid metal containing oxide layer and preparation method thereof

A liquid metal, high-speed flow technology, applied in the field of microelectronics, can solve problems such as failure of aluminum-based heat sink components, catastrophic accidents, and difficulty in normal flow of liquid metal, so as to prevent embrittlement reactions and broaden the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

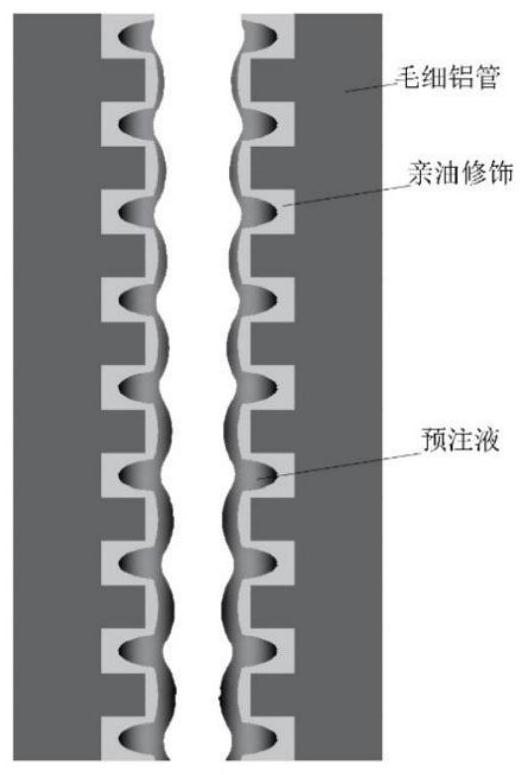

[0055] A method for preparing a capillary aluminum tube capable of high-speed flow of a gallium-based liquid metal containing an oxide layer, comprising the following steps:

[0056] (1) Pretreatment of capillary aluminum tube

[0057] After filling the capillary aluminum tube with acetone, seal it, and ultrasonically clean it for 5-10 minutes, with an ultrasonic frequency of 40-60kHz; after pouring out the acetone, inject alcohol, seal it, and ultrasonically clean it for 5-20min, with an ultrasonic frequency of 40-60kHz; after pouring out the alcohol Inject deionized water, seal, and ultrasonically clean for 5-15min at a frequency of 40-60kHz.

[0058] Put the above-mentioned cleaned capillary aluminum tube in an oven at 60-150° C. for drying treatment for 20-120 minutes, and seal it for future use.

[0059] (2) Electrochemical processing of the inner wall of the capillary aluminum tube

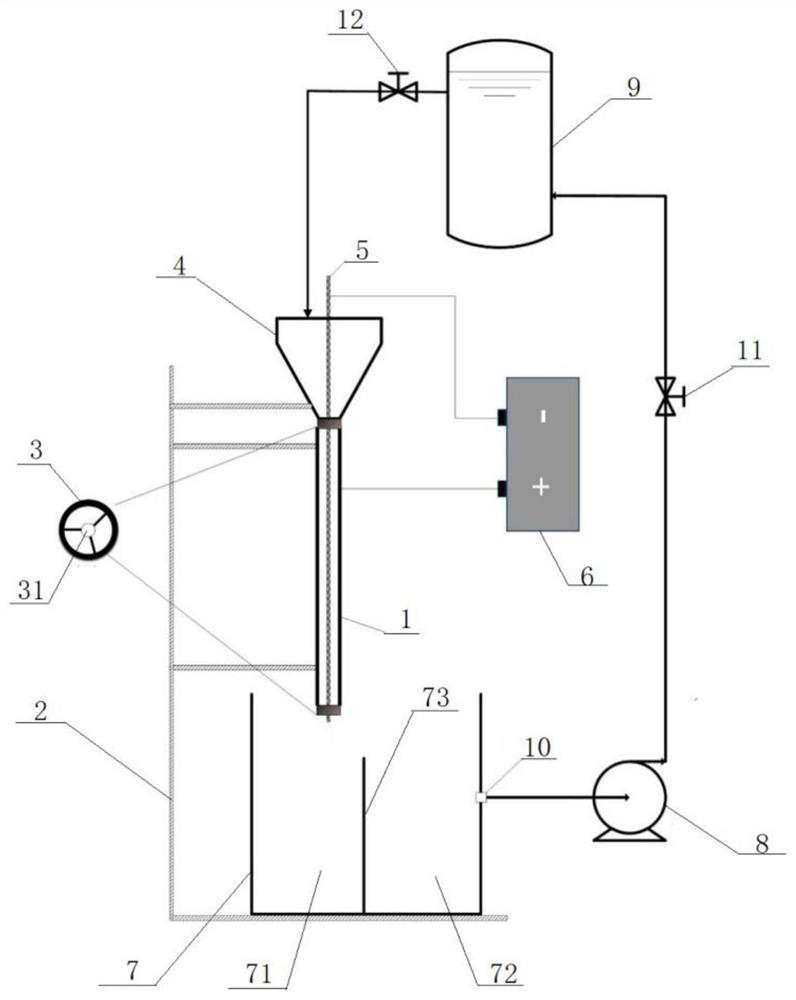

[0060] The capillary electrochemical reaction device is used to electrochemically proc...

Embodiment 1

[0084] (1) Pretreatment of capillary aluminum tube

[0085] After filling the capillary aluminum tube with an inner diameter of 200 μm with acetone, seal it, and ultrasonically clean it for 6 minutes at an ultrasonic frequency of 40 kHz; pour out the acetone and inject alcohol, seal it, and ultrasonically clean it for 6 minutes at an ultrasonic frequency of 40 kHz; pour out the alcohol and inject deionized water , sealed, ultrasonic cleaning 8min, ultrasonic frequency 40kHz. The above-mentioned cleaned capillary aluminum tubes were dried in an oven at 60° C. for 30 minutes. Save it for later use.

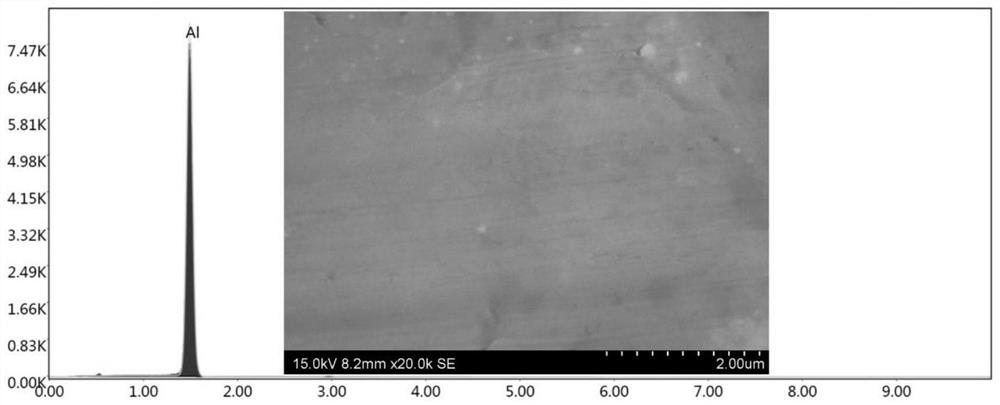

[0086] The surface microstructure and elemental analysis of the inner wall of the capillary aluminum tube after surface cleaning are as follows: image 3 As shown, the XRD spectrum is as Figure 4 As shown, the corresponding obtained element amounts are shown in Table 1. From image 3 It can be seen from the microstructure of the inner wall surface of the capillary aluminum tub...

Embodiment 2

[0109] (1) Pretreatment of capillary aluminum tube

[0110] A capillary aluminum tube with an inner diameter of 500 μm was used, and the pretreatment parameters and process were the same as in Example 1.

[0111] (2) Electrochemical processing of the inner wall of the capillary aluminum tube

[0112] The electrochemical processing device is the same as that in Example 1.

[0113] The concentration of the electrolyte solution used in electrochemical machining is 0.25mol / L NaCl solution, and the current density is 250mA / cm 2 , the reaction temperature is 25°C, and the reaction time is 15 minutes. After the reaction, inject absolute ethanol into the capillary aluminum tube, seal it, and ultrasonically clean it for 5 minutes, and the ultrasonic frequency is 40kHz; after pouring out the alcohol, inject deionized water, seal it, and ultrasonically clean it 8min, the ultrasonic frequency is 40kHz. Finally, the capillary aluminum tube was dried in an oven at 60 °C for 25 min.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com