A waterproof building exterior wall insulation structure and its construction method

A technology for building exterior walls and waterproofing, which is applied to building components, building structures, buildings, etc., can solve the problems of increasing the weight of the thermal insulation layer, separating the thermal insulation layer from the wall, and deteriorating the thermal insulation effect. Crack resistance and deformation compensation performance, the effect of tensile strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

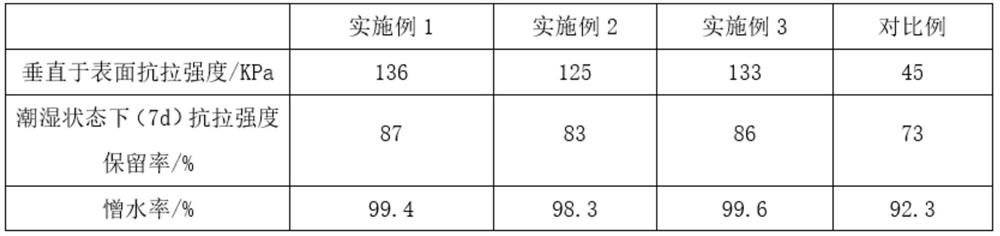

Embodiment 1

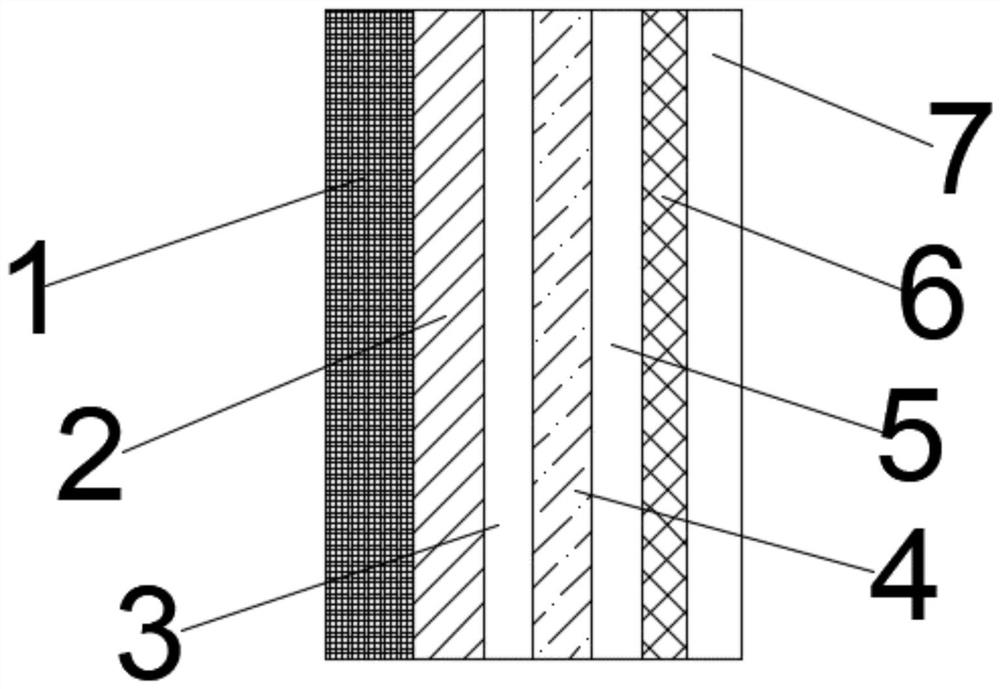

[0051] A waterproof building exterior wall insulation structure, comprising an exterior wall body 1, the surface of the exterior wall body 1 is sequentially provided with a leveling layer 2, a first adhesive layer 3, a thermal insulation layer 4, a second Two bonding layer 5, waterproof layer 6 and protective layer 7;

[0052] The leveling layer 2 is coated with concrete mortar; the concrete mortar consists of the following components in parts by weight:

[0053] 90 parts of Portland cement, 135 parts of coarse aggregate, 100 parts of fine aggregate, 45 parts of water, 50 parts of rubber powder, 22 parts of fly ash, 13 parts of glass fiber, 10 parts of basalt fiber, and 0.7 part of water reducer.

[0054] The rubber powder is obtained by grinding waste rubber particles or shredded rubber sheets, wherein the particle size of the rubber powder is 50-200 μm.

[0055] Both the first adhesive layer 3 and the second adhesive layer 5 are coated with epoxy resin adhesive; the epoxy r...

Embodiment 2

[0088] A waterproof building exterior wall insulation structure, comprising an exterior wall body 1, the surface of the exterior wall body 1 is sequentially provided with a leveling layer 2, a first adhesive layer 3, a thermal insulation layer 4, a second Two bonding layer 5, waterproof layer 6 and protective layer 7;

[0089] The leveling layer 2 is coated with concrete mortar; the concrete mortar consists of the following components in parts by weight:

[0090] 80 parts of Portland cement, 120 parts of coarse aggregate, 80 parts of fine aggregate, 40 parts of water, 40 parts of rubber powder, 20 parts of fly ash, 12 parts of glass fiber, 8 parts of basalt fiber, and 0.5 part of water reducing agent.

[0091] The rubber powder is obtained by grinding waste rubber particles or shredded rubber sheets, wherein the particle size of the rubber powder is 50-200 μm.

[0092] Both the first adhesive layer 3 and the second adhesive layer 5 are coated with epoxy resin adhesive; the epox...

Embodiment 3

[0125] A waterproof building exterior wall insulation structure, comprising an exterior wall body 1, the surface of the exterior wall body 1 is sequentially provided with a leveling layer 2, a first adhesive layer 3, a thermal insulation layer 4, a second Two bonding layer 5, waterproof layer 6 and protective layer 7;

[0126] The leveling layer 2 is coated with concrete mortar; the concrete mortar consists of the following components in parts by weight:

[0127] 100 parts of Portland cement, 150 parts of coarse aggregate, 120 parts of fine aggregate, 50 parts of water, 60 parts of rubber powder, 25 parts of fly ash, 14 parts of glass fiber, 15 parts of basalt fiber, and 1 part of water reducer.

[0128] The rubber powder is obtained by grinding waste rubber particles or shredded rubber sheets, wherein the particle size of the rubber powder is 50-200 μm.

[0129] Both the first adhesive layer 3 and the second adhesive layer 5 are coated with epoxy resin adhesive; the epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com