Preparation method of impact-resistant easily-degradable environment-friendly non-woven fabric

An easy-degradable, non-woven fabric technology, applied in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problems that limit the wide application of impact-resistant non-woven fabrics, limited mechanical properties, etc., and achieve good processing thermal stability , good softness and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing an impact-resistant and easily degradable environmentally friendly non-woven fabric, comprising the following steps:

[0026] S1. Mix 50kg of polylactic acid, 10kg of epoxy resin, 4kg of carbon nanotubes, and 50kg of acetone with a molecular weight of 100,000 and a melt flow rate of 5g / 10min (210°C, 2.16kg), sonicate for 2 hours, and the ultrasonic power is 500W , remove acetone, add 1kg tetrahydrophthalic anhydride, 25kg montmorillonite, and react at 130°C for 20min to obtain pretreated polylactic acid;

[0027] S2, 100kg pretreated polylactic acid, 10kg polyadipate-terephthalate-butylene glycol ester resin, 15kg nano-silicon dioxide, 1kg disproportionated rosin are mixed uniformly, and are sent into a twin-screw extruder for extrusion, wherein The temperature of the first stage is 120°C, the temperature of the second stage is 135°C, the temperature of the third stage is 155°C, the temperature of the fourth stage is 158°C, the temperature of the ...

Embodiment 2

[0030] A method for preparing an impact-resistant and easily degradable environmentally friendly non-woven fabric, comprising the following steps:

[0031] S1. Mix 80kg of polylactic acid, 4kg of epoxy resin, 8kg of carbon nanotubes, and 30kg of acetone with a molecular weight of 500,000 and a melt flow rate of 50g / 10min (210°C, 2.16kg), and ultrasonically treat it for 4 hours with an ultrasonic power of 300W. , remove acetone, add 2kg tetrahydrophthalic anhydride, 15kg montmorillonite, and react at 150°C for 10min to obtain pretreated polylactic acid;

[0032] S2, 100kg pretreatment polylactic acid, 20kg polyadipate-terephthalate-butylene glycol ester resin, 5kg fly ash, 3kg epoxy soybean oil are mixed uniformly, send into twin-screw extruder and extrude, The temperature of the first stage is 110°C, the temperature of the second stage is 142°C, the temperature of the third stage is 150°C, the temperature of the fourth stage is 162°C, the temperature of the fifth stage is 170°...

Embodiment 3

[0035] A method for preparing an impact-resistant and easily degradable environmentally friendly non-woven fabric, comprising the following steps:

[0036] S1. Mix 60kg of polylactic acid, 8kg of epoxy resin, 5kg of carbon nanotubes, and 45kg of acetone with a molecular weight of 200,000 and a melt flow rate of 10g / 10min (210°C, 2.16kg), and perform ultrasonic treatment for 2.5 hours. The ultrasonic power is 450W, remove acetone, add 1.3kg tetrahydrophthalic anhydride, 22kg montmorillonite, and react at 135°C for 18min to obtain pretreated polylactic acid;

[0037] S2. Mix 100kg of pretreated polylactic acid, 13kg of polyadipate-terephthalate-butylene glycol ester resin, 12kg of calcined clay, and 1.5kg of dibutyltin dilaurate into a twin-screw extruder to extrude The temperature of the first stage is 117°C, the temperature of the second stage is 136°C, the temperature of the third stage is 154°C, the temperature of the fourth stage is 159°C, the temperature of the fifth stage...

PUM

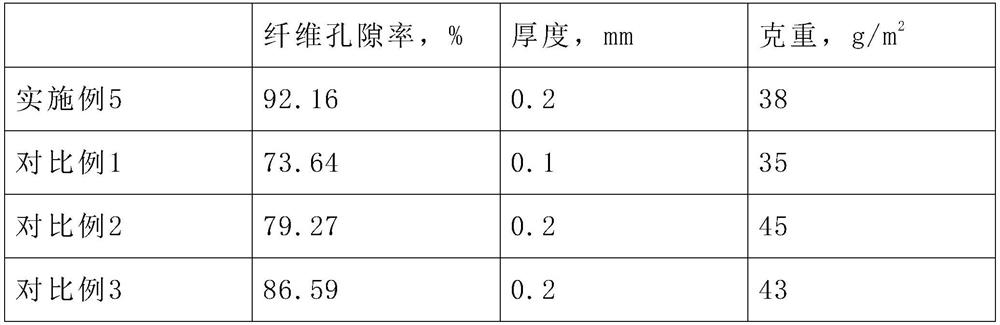

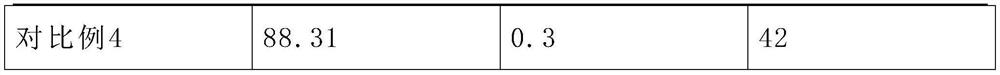

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com