Two-component isocyanate coating

An isocyanate, two-component technology, applied in the field of coating preparation, can solve the problems of no self-cleaning function, poor anti-corrosion and anti-rust performance, poor scratch resistance, etc., to achieve improved self-cleaning performance, strong scratch resistance, Strong anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

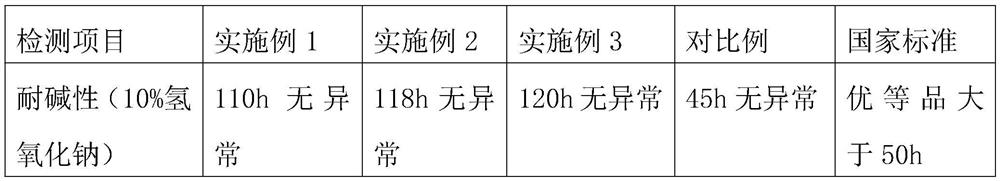

Embodiment 1

[0023] A two-component isocyanate coating includes component A and component B, and component A contains the following raw materials in parts by weight: hydroxyacrylic resin 20kg, polyacrylate aqueous dispersion 15kg, water-based polyaniline emulsion 5kg, inorganic pigment 8kg, filler 10kg , graphite phase carbon nitride 5kg, defoamer 1kg, film-forming aid 3kg, neutralizer 1kg, dispersant 1kg, thickener 2kg, distilled water 5kg; wetting agent 2kg, leveling agent 2kg, rust inhibitor 0.5kg, guaiacol 0.5kg, cellulose 1kg;

[0024] Component A and B are mixed according to the mass ratio of 4:1, so the water-based isocyanate curing agent is 20.625kg, and the water-based isocyanate curing agent is composed of sulfamic acid, dimethylcyclohexylamine and toluene diisocyanate according to the mass ratio of 4 :3:2 prepared.

[0025] Wetting agent is the mixture of ethanol and propylene glycol in the present embodiment; Described cellulose is cellulose acetate butyrate; Antirust agent is...

Embodiment 2

[0027] A two-component isocyanate coating consists of component A and component B, and component A contains the following raw materials in parts by weight: 45kg of hydroxyl acrylic resin, 28kg of polyacrylate aqueous dispersion, 8kg of water-based polyaniline emulsion, 18kg of inorganic pigments, and 20kg of fillers , graphite phase carbon nitride 15kg, defoamer 2kg, film-forming aid 7kg, neutralizer 3kg, dispersant 3kg, thickener 5kg, distilled water 15kg, wetting agent 5kg, leveling agent 3kg, rust inhibitor 2kg , guaiacol 1kg, cellulose 3kg.

[0028] Components A and B are mixed according to a mass ratio of 4:1. The component B is a water-based isocyanate curing agent with a weight of 45.75kg. The water-based isocyanate curing agent is composed of sulfamic acid, dimethylcyclohexylamine and toluene Diisocyanate is prepared according to the mass ratio of 4:3:2.

[0029] In this implementation, the wetting agent is a mixture of ethanol and propylene glycol; the cellulose is c...

Embodiment 3

[0031] A two-component isocyanate coating consists of component A and component B, and component A contains the following raw materials in parts by weight: 30kg of hydroxyl acrylic resin, 25kg of polyacrylate aqueous dispersion, 7kg of water-based polyaniline emulsion, 15kg of inorganic pigment, and 15kg of filler , graphite phase carbon nitride 10kg, defoamer 1.5kg, film-forming aid 6kg, neutralizer 2kg, dispersant 2kg, thickener 4kg, distilled water 12kg, wetting agent 3kg, leveling agent 1.5kg, antirust Agent 1kg, guaiacol 0.8kg, cellulose 2kg.

[0032] Components A and B are mixed in a mass ratio of 4:1. The component B is a water-based isocyanate curing agent with a weight of 34.45kg. The water-based isocyanate curing agent is composed of sulfamic acid, dimethylcyclohexylamine and toluene Diisocyanate is prepared according to the mass ratio of 4:3:2.

[0033] In this implementation, the wetting agent is a mixture of ethanol and propylene glycol; the cellulose is cellulos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com