VOCs catalytic combustion monolithic metal foam catalyst and preparation and application thereof

An integral catalyst, catalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. problem, to achieve the effect of simple and flexible preparation method, strong thermal shock resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of noble metal monolith catalyst of the present invention comprises the steps:

[0047] (1) Preparation of chloroplatinic acid solution: weigh 1.66-8.3g of H 2 PtCl 6 ·6H 2 Dissolve O in 250ml of water, and configure it into a mother liquor of 2.5-12.5g / L (based on the mass of platinum), and prepare chloroplatinic acid solutions of different concentrations with the mother liquor of 2.5-12.5g / L as the impregnated adsorption solution.

[0048] (2) Preparation of chloropalladium acid solution: weigh 0.5-2.5g of PdCl 2 Dissolve in 100ml of water, then add 2.78~13.9ml2.0mol / L HCl solution, then heat the mixed solution until dissolved, and finally settle to 250ml of mother liquor with a concentration of 1.2~6g / L (based on the quality of palladium). The 1.2-6g / L mother liquor is prepared with different concentrations of chloropalladium acid solution as the impregnation and adsorption solution.

[0049] (3) Pretreatment of foamed nickel: first put the...

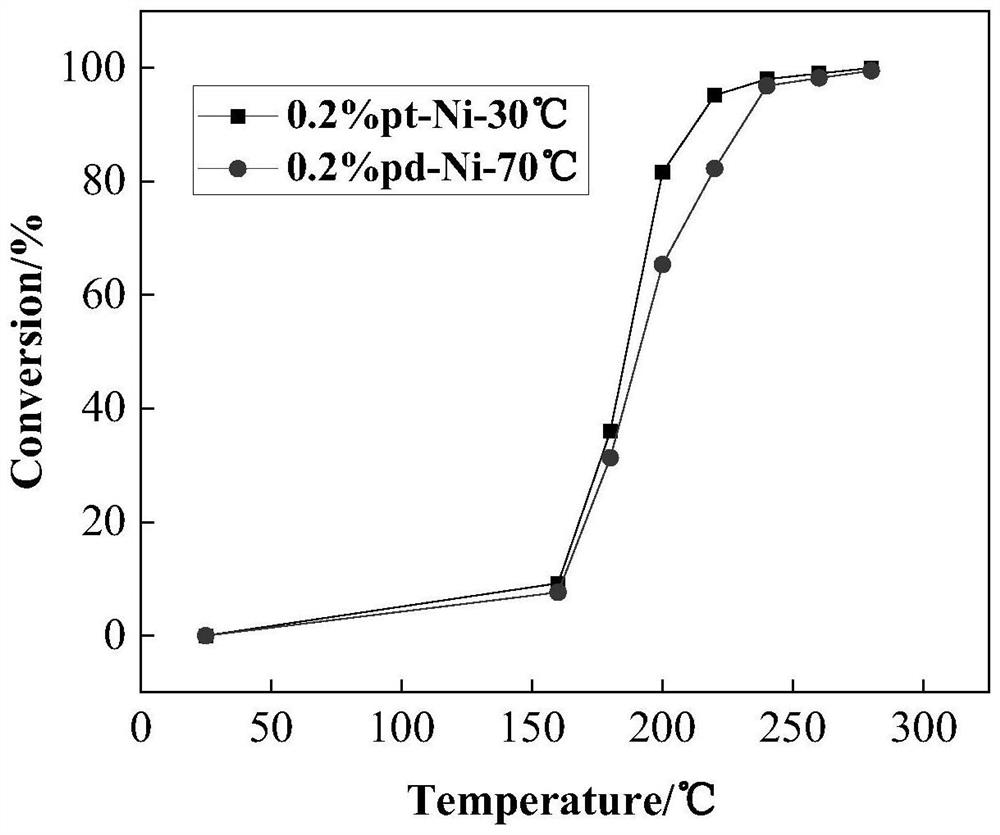

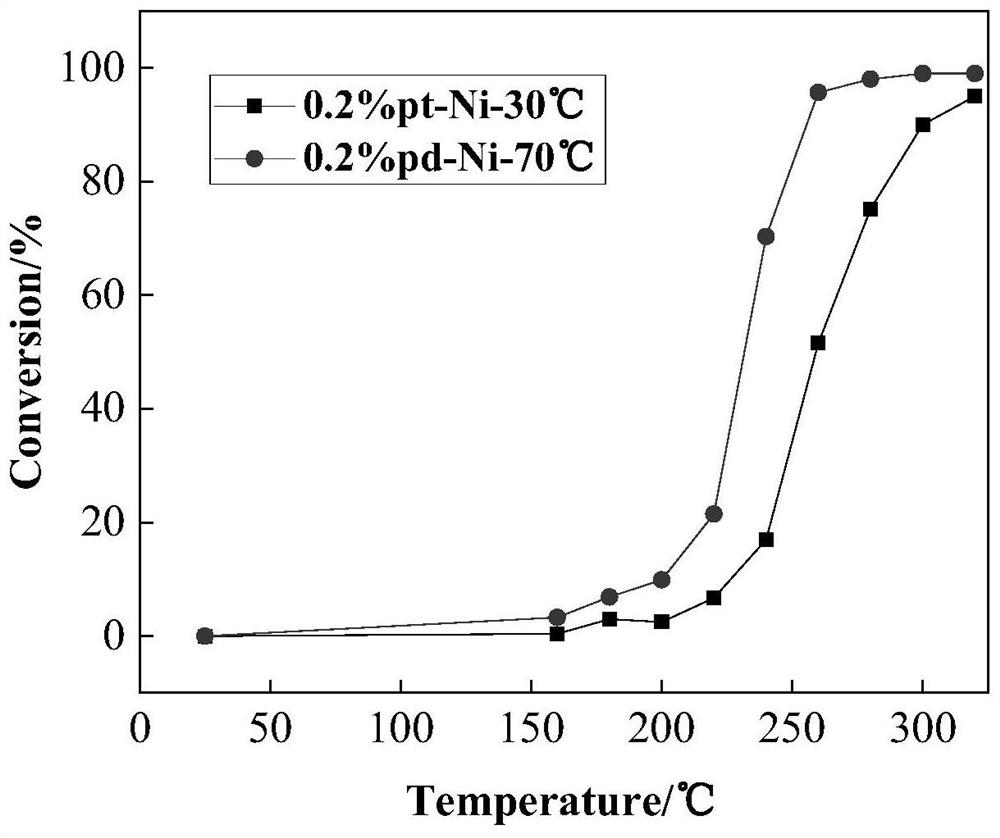

Embodiment 1

[0056] Take 0.72ml of 2.5g / L (based on the mass of platinum) mother liquor and 9.28ml of water and mix it into a 10ml solution in a centrifuge tube. Put 0.9g of pretreated nickel foam into the centrifuge tube and place in a water bath at 20°C Under dipping and replacement, measure the concentration change of the solution every 10 minutes with a UV spectrophotometer until the Pt ion concentration becomes 0, then filter and dry, and the obtained product is recorded as 0.2% Pt / Ni-foam-20°C.

Embodiment 2

[0058] The conditions are the same as in Example 1, and the temperature of the water bath is changed to 30°C, which is recorded as 0.2%Pt / Ni-foam-30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com