Sound insulation type elastic coiled material floor for rail transit and preparation method thereof

A technology of rail transit and coiled flooring, applied in the direction of insulation layer, covering/lining, building structure, etc., can solve the problem of reducing the mechanical properties and wear resistance of materials, without considering the needs of sound insulation and noise reduction performance, and the comprehensive performance of materials Insufficient problems, to achieve low smoke density and smoke toxicity, reduce additional use, and increase flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

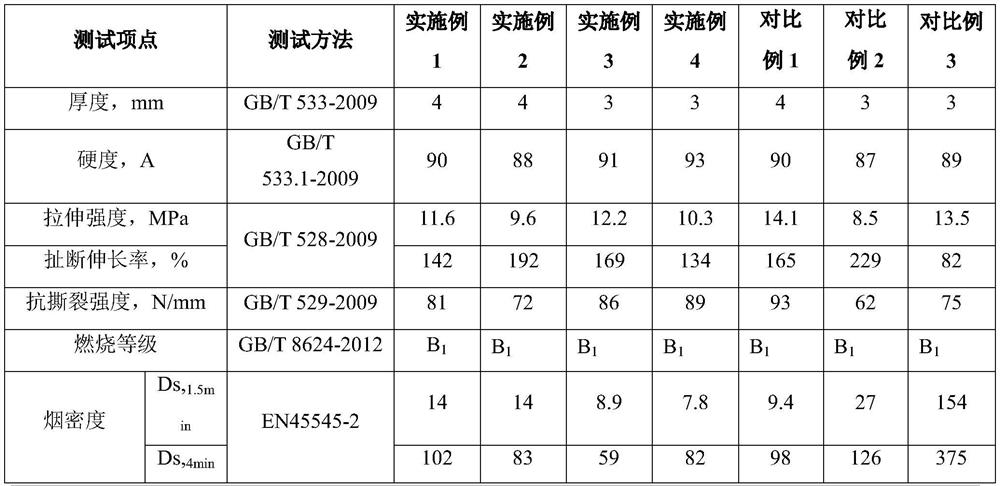

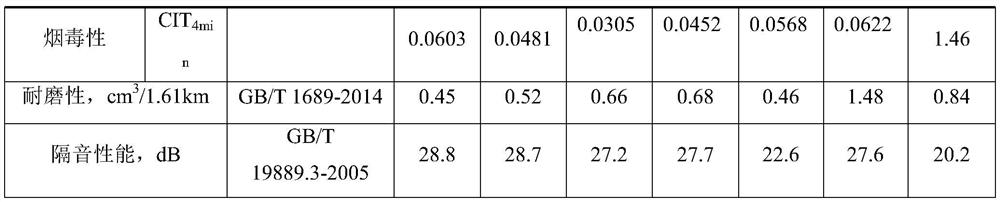

Examples

preparation example Construction

[0067] In a specific embodiment, the preparation method of the sound-insulating elastic coil floor for rail transit comprises the following steps:

[0068] Internal mixing: The configured and weighed sound insulation layer and wear-resistant layer materials are internally mixed with an internal mixer respectively. It is required that the resin is melted and plasticized, and all materials are mixed evenly. The internal mixing temperature is controlled at 180°C to 220°C.

[0069] Extrusion or calendering: Extrude or calender the plasticized and mixed sound-insulating layer and wear-resistant layer materials respectively into sheets of certain width and thickness, and the extrusion or calendering temperature is 160°C to 210°C.

[0070] Composite: The sound insulation layer sheet, the glass fiber stable layer mesh cloth and the wear-resistant layer sheet are compositely formed by hot rolling. The hot rolling temperature is 150℃~180℃. After cooling, the composite sheet needs to be p...

Embodiment 1

[0073] Sound insulation layer formula: 20 parts of propylene-based elastomer, 15 parts of SEBS, 50 parts of barium sulfate, 50 parts of aluminum hydroxide, 0.2 parts of toner, 0.5 parts of coupling agent, and 0.5 parts of antioxidant.

[0074] Wear-resistant layer formula: 15 parts of acrylic elastomer, 20 parts of SEBS, 15 parts of TPU, 50 parts of aluminum hydroxide, 4 parts of maleic anhydride grafted SEBS, 4 parts of silicone powder, 0.2 parts of toner, 0.5 parts of antioxidant .

[0075] Preparation:

[0076] Internal mixing: The configured and weighed sound insulation layer and wear-resistant layer materials are internally mixed with an internal mixer respectively. It is required that the resin is melted and plasticized, and all materials are mixed evenly. The internal mixing temperature is 180°C.

[0077] Extrusion or calendering: Extrude the plasticized and mixed sound-insulating layer and wear-resistant layer materials into sheets with a thickness of 2 mm, and the ex...

Embodiment 2

[0081] Sound insulation layer formula: 15 parts of propylene-based elastomer, 20 parts of SEBS, 50 parts of barium sulfate, 50 parts of aluminum hydroxide, 0.2 parts of toner, 0.5 parts of coupling agent, and 0.5 parts of antioxidant.

[0082] Wear-resistant layer formula: 15 parts of propylene-based elastomer, 25 parts of SEBS, 10 parts of TPU, 40 parts of aluminum hydroxide, 10 parts of aluminum diethyl hypophosphite, 5 parts of maleic anhydride grafted SEBS, 4 parts of silicone powder, color 0.2 part of agent, 0.5 part of antioxidant.

[0083] Preparation:

[0084] Internal mixing: The configured and weighed sound insulation layer and wear-resistant layer materials are internally mixed with an internal mixer respectively. It is required that the resin is melted and plasticized, and all materials are mixed evenly. The internal mixing temperature is 180°C.

[0085] Extrusion or calendering: Extrude the plasticized and mixed sound-insulating layer and wear-resistant layer mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com