Environment-friendly composite plastic with pearlescent effect and multicolor pattern effect and preparation method of environment-friendly composite plastic

A composite plastic and effect technology, which is applied in the field of environmentally friendly composite plastic and its preparation, can solve problems such as troublesome processing procedures, environmental hazards, and pollution, and achieve the effects of adjusting mechanical physical properties and processing performance, increasing yield, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

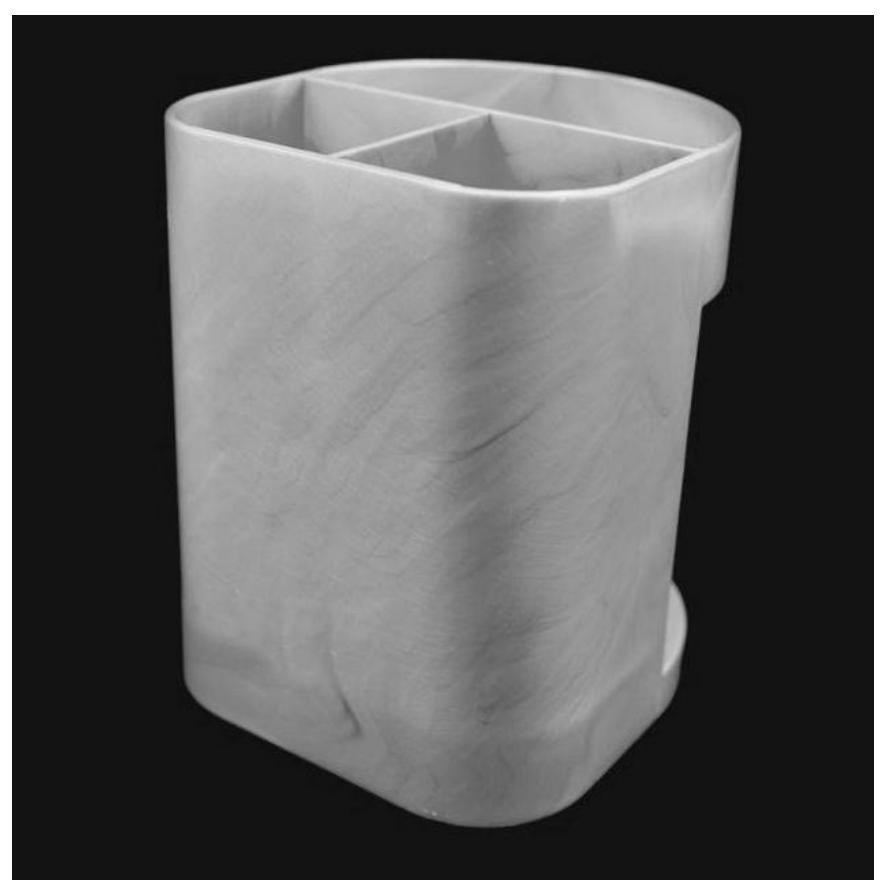

Image

Examples

Embodiment 1

[0039] (1) First, accurately weigh the main materials, auxiliary materials and polymer compatibilizer according to the parts shown in Table 1, and then add them to the high-speed mixer. The specific reagents are styrene-butadiene transparent impact resin 803, PP, SAN, POE, MS, PP -G-MMA and HIPS; under the condition of 2000 rpm, carry out the initial mixing for 3 minutes, so that the added substances are mixed evenly, without sticking to the sheet, sticking to the wall, or settling at the bottom;

[0040] (2) Stop the high-speed mixer, open the cover and check to meet the appeal requirements, then add additives and lubricants, the specific reagents are EBS, PETS, anti-aging agent 168, anti-aging agent 1010, Cast, Hst and light stabilizer UV-531, mix Uniformly used as powder, cover and continue to stir, under the condition of 2000 rpm, carry out initial mixing for 5 minutes, so that the powder is adsorbed on the plastic particles, the final temperature of the initial mixing is 6...

Embodiment 2

[0047] The components and proportions of Example 2 are shown in the table below, and its specific preparation process is the same as that of Example 1.

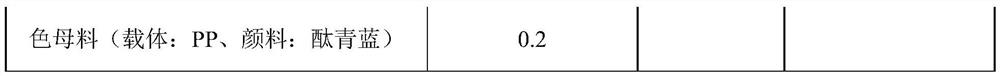

[0048] Table 2: Component composition and weight ratio of embodiment 2

[0049]

Embodiment 3

[0051] The components and proportions of Example 3 are shown in the table below, and its specific preparation process is the same as that of Example 1.

[0052] Table 3: Component composition and parts by weight of Example 3

[0053]

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com