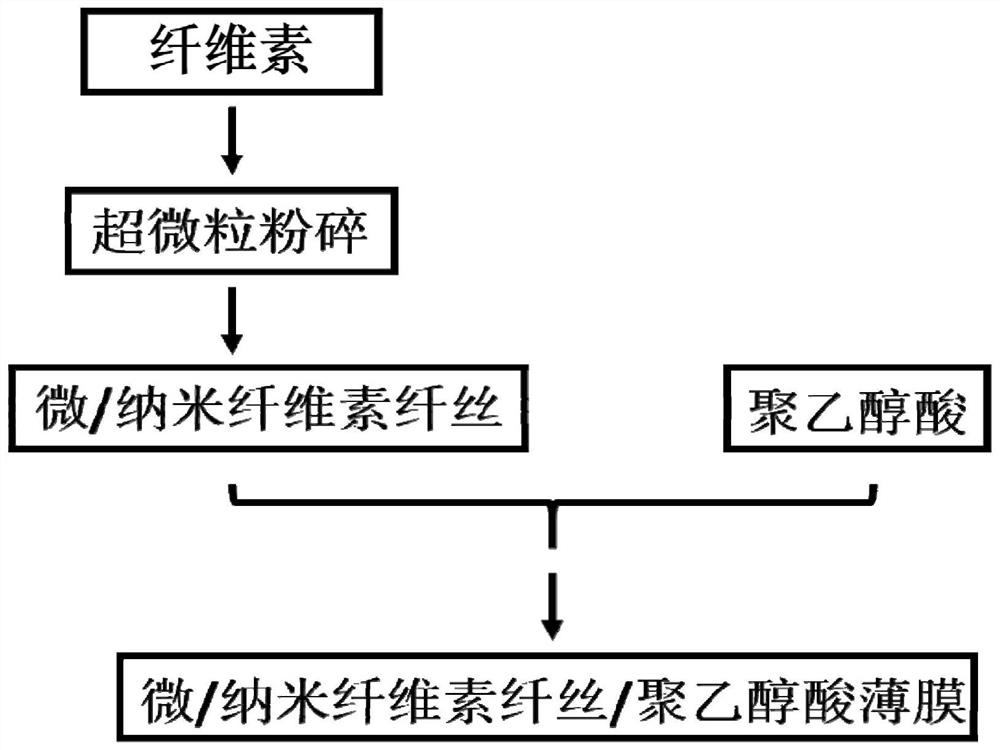

A kind of micro/nano cellulose fibril/polyglycolic acid film and its preparation method and application

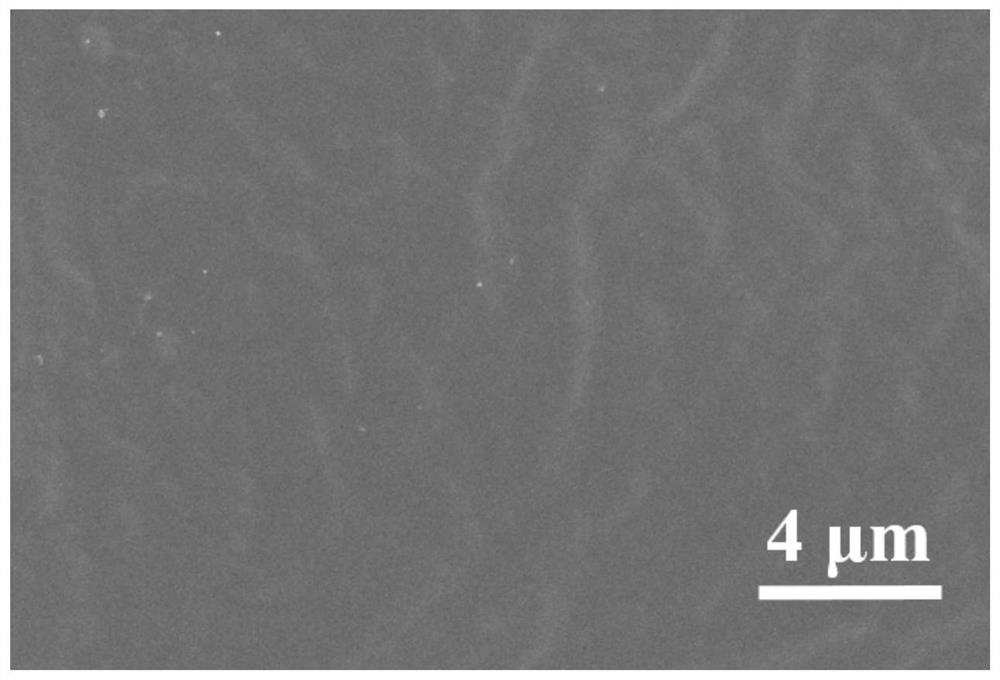

A technology of nanocellulose and polyglycolic acid, applied in the field of degradable films, to achieve the effect of expanding the scope of application, good transparency and rich hydroxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A micro / nano cellulose fibril / polyglycolic acid film, the preparation method of which is as follows:

[0041] (1) Soak 50 g of dry weight bacterial cellulose in water for 12 hours, and then prepare a pulp suspension with a concentration of 1% by mass.

[0042] (2) Take 2.5L of the pulp suspension with a mass fraction of 1% obtained in step (1), and pulverize it with a superfine pulverizer (Japan Masuko Sangyo Co., Ltd., model: MKCA6-2J), and the rotating speed is 1500r / min, the gap is -20μm, and the cyclic grinding treatment is 10 times to obtain the micro / nanocellulose fibrils of the water dispersion system, and then part of the water is removed by centrifugation, and the water dispersion of the micro / nanocellulose fibrils with a mass fraction of 15% is prepared. liquid.

[0043] (3) Take polyglycolic acid (polymerization degree of 170) to prepare a polyglycolic acid aqueous solution with a mass fraction of 30%.

[0044] (4) Take 20 g of the micro / nano cellulose fib...

Embodiment 2

[0046]A micro / nano cellulose fibril / polyglycolic acid film, the preparation method of which is as follows:

[0047] (1) 200 g of hardwood pulp in dry weight was soaked in water for 48 hours, and then prepared into a pulp suspension with a mass percentage concentration of 8%.

[0048] (2) Take 2.5L of the pulp suspension with a mass fraction of 8% obtained in step (1), and pulverize it with a superfine pulverizer (Japan Masuko Sangyo Co., Ltd., model: MKCA6-2J), and the rotating speed is 3000r / min, the gap is -10 μm, and the cyclic pulverization process is 30 times to obtain the micro / nanocellulose fibrils of the water dispersion system, and then part of the water is removed by centrifugation, and the water dispersion of the micro / nanocellulose fibrils with a mass fraction of 10% is prepared. liquid.

[0049] (3) Polyglycolic acid (polymerization degree of 1000) is taken to prepare a polyglycolic acid ethanol solution with a mass fraction of 20%.

[0050] (4) Take 10 g of th...

Embodiment 3

[0052] A micro / nano cellulose fibril / polyglycolic acid film, the preparation method of which is as follows:

[0053] (1) 200 g of dry weight softwood pulp was soaked in water for 48 hours, and then prepared into a pulp suspension with a mass percentage concentration of 4%.

[0054] (2) Take 2.5L of the pulp suspension with a mass fraction of 4% obtained in the step (1), and pulverize it with a superfine pulverizer (Japan Masuko Sangyo Co., Ltd., model: MKCA6-2J), and the rotating speed is 3000r / min, the gap is -10 μm, and the cyclic grinding treatment is 20 times to obtain the micro / nanocellulose fibrils of the water dispersion system, and then part of the water is removed by centrifugation, and the water dispersion of the micro / nanocellulose fibrils with a mass fraction of 15% is prepared. liquid.

[0055] (3) Take polyglycolic acid (polymerization degree of 2100) to prepare a polyglycolic acid methanol solution with a mass fraction of 20%.

[0056] (4) Take 100 g of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com