Preparation method of high-reliability long-life silicon nitride ceramic ball for aircraft bearing

A silicon nitride ceramic ball and reliability technology, applied in the field of silicon nitride ceramic ball manufacturing, can solve the problems of reducing the strength, hardness and other mechanical properties of the silicon nitride ceramic ball, affecting the reliability and fatigue life of the ceramic ball and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

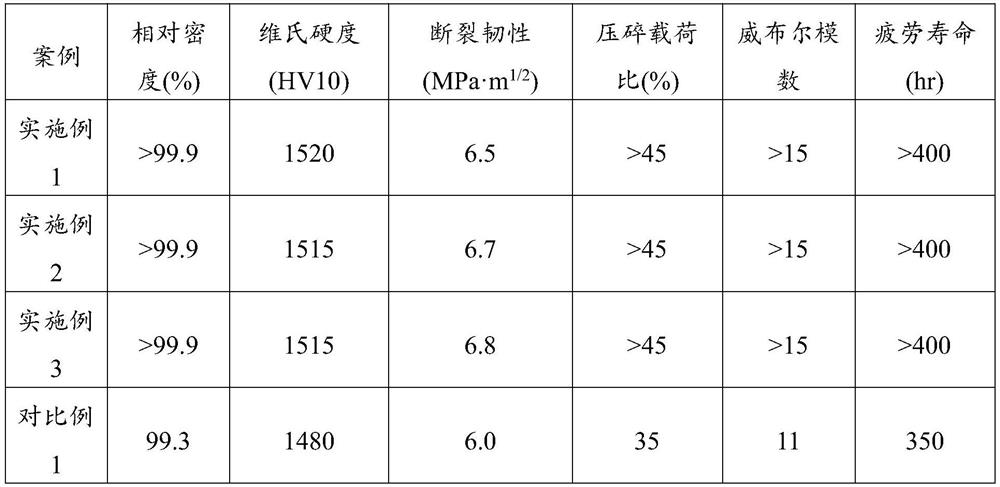

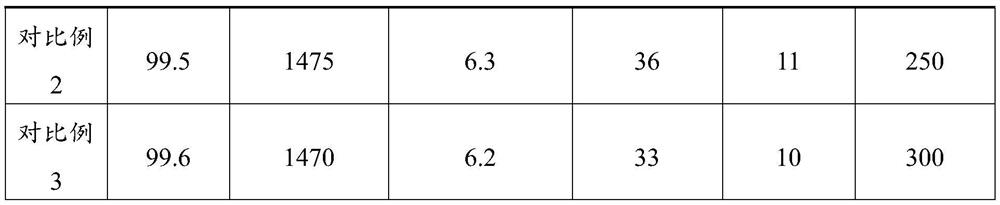

Examples

preparation example Construction

[0022] The invention provides a method for preparing high-reliability and long-life silicon nitride ceramic balls for aviation bearings, which comprises the following steps:

[0023] mixing aluminum isopropoxide, organic solvent, silicon nitride powder and metal acetate aqueous solution, followed by hydrolysis and first spray drying to obtain a mixed powder;

[0024] Calcining the mixed powder to obtain silicon nitride powder coated with sintering aid;

[0025] Grinding the sintering aid-coated silicon nitride powder, mixing it with a binder, and performing a second spray drying to obtain granulated powder;

[0026] The granulated powder is sequentially subjected to molding, debinding and sintering to obtain silicon nitride ceramic balls.

[0027] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0028] In the invention, aluminum isopropoxide, organic solvent,...

Embodiment 1

[0049] 12kg (the amount converted to alumina is 3kg) of aluminum isopropoxide (C 9 h 21 AlO 3 ) was dissolved in absolute ethanol (100kg), added 92kg silicon nitride powder, stirred for 3h, then added yttrium acetate (Y(C 2 h 3 o 2 ) 3 4H 2 (2) deionized water (concentration of yttrium acetate aqueous solution is 200g / L), stir 1.5h, carry out spray drying immediately afterwards, obtain the mixed powder body of silicon nitride and sintering aid precursor, described mixed powder body is in Calcined at 450°C for 3 hours to obtain alumina and yttrium oxide-coated silicon nitride powder (100kg);

[0050] Using absolute ethanol as a solvent and silicon nitride as a grinding ball, grind the aluminum oxide and yttrium oxide-coated silicon nitride powder in a stirring ball mill for 6 hours, so that the particle size of the powder is D 50 After reaching below 0.6 microns, add 1.5kg of binder PVB and 1kg of polyacrylic acid emulsion to the obtained slurry after grinding, stir for ...

Embodiment 2

[0055] 20kg (the amount converted to alumina is 5kg) of aluminum isopropoxide (C 9 h 21 AlO 3 ) was dissolved in dehydrated alcohol (120kg), added 92kg silicon nitride powder, stirred for 3h, then added yttrium acetate (Y(C 2 h 3 o 2 ) 3 4H 2 (2) deionized water (concentration of yttrium acetate aqueous solution is 200g / L), stir 2h, carry out spray drying immediately afterwards, obtain the mixed powder body of silicon nitride and sintering aid precursor, described mixed powder body is in 500 Calcined at ℃ for 2h to obtain aluminum oxide and yttrium oxide coated silicon nitride powder (100kg);

[0056] Using absolute ethanol as a solvent and silicon nitride as a grinding ball, grind the aluminum oxide and yttrium oxide-coated silicon nitride powder in a stirring ball mill for 6 hours, so that the particle size of the powder is D 50 After reaching below 0.6 microns, add 1.5kg of binder PVB and 1kg of polyacrylic acid emulsion to the obtained slurry after grinding, stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com