Preparation method of praseodymium-ytterbium co-doped fluorine-aluminum glass with light-emitting broadband of 3.5 microns

A fluorine-aluminum and glass technology, applied in the field of preparation of praseodymium-ytterbium co-doped fluorine-aluminum glass, can solve the problems of high cost and use conditions, slow research progress, complicated installation, etc., and achieve good spectral transmission width and transmission performance, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0023] Preparation of fluoroaluminosilicate glass in a broadband 3.5 micron light emitting praseodymium Yb co-doped, comprising the steps of:

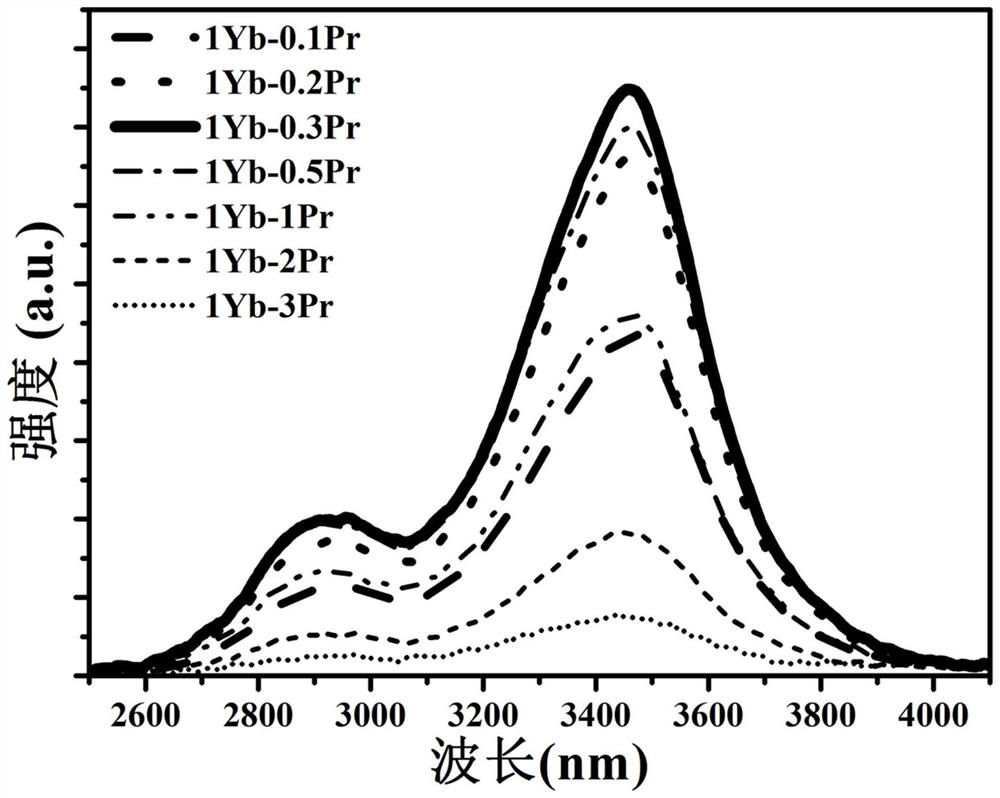

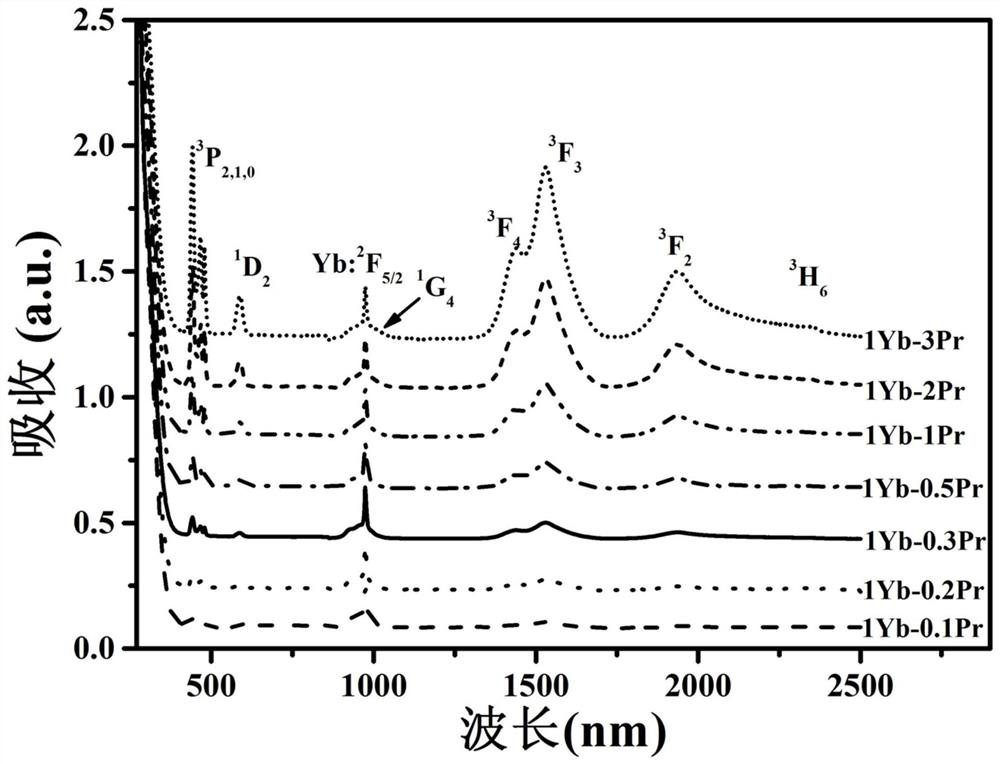

[0024] Step 1: The chemical raw materials are weighed according to the molar percentage formulated as follows, and then mixed thoroughly ground in an agate mortar: 30AlF 3 -15BaF 2 - (20-x-y) YF 3 -25PbF 2 -10MgF 2 -xPrF 3 -yYbF 3 (X = 0,0.1,0.2,0.3,0.5,1,2,3; y = 1).

[0025] Step 2: mixing the raw materials charged in a crucible, and in a glove box, high temperature fired melting furnace 930 degrees Celsius.

[0026] Step 3: The molten liquid was poured into a 370 ° C preheated mold copper plate for 3 hours, then slowly cooled to room temperature to obtain fluoroaluminosilicate glass with different concentrations of praseodymium and ytterbium co-doped.

[0027] Step 4: Yb co-doped praseodymium fluoroalum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com