Filtering device for nitrile rubber material manufacturing

A technology of nitrile rubber and filter device, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of poor insulation performance, small amplitude, poor low temperature resistance, etc., and achieve the adjustment of feeding angle, convenient feeding angle, The effect of avoiding the spread of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

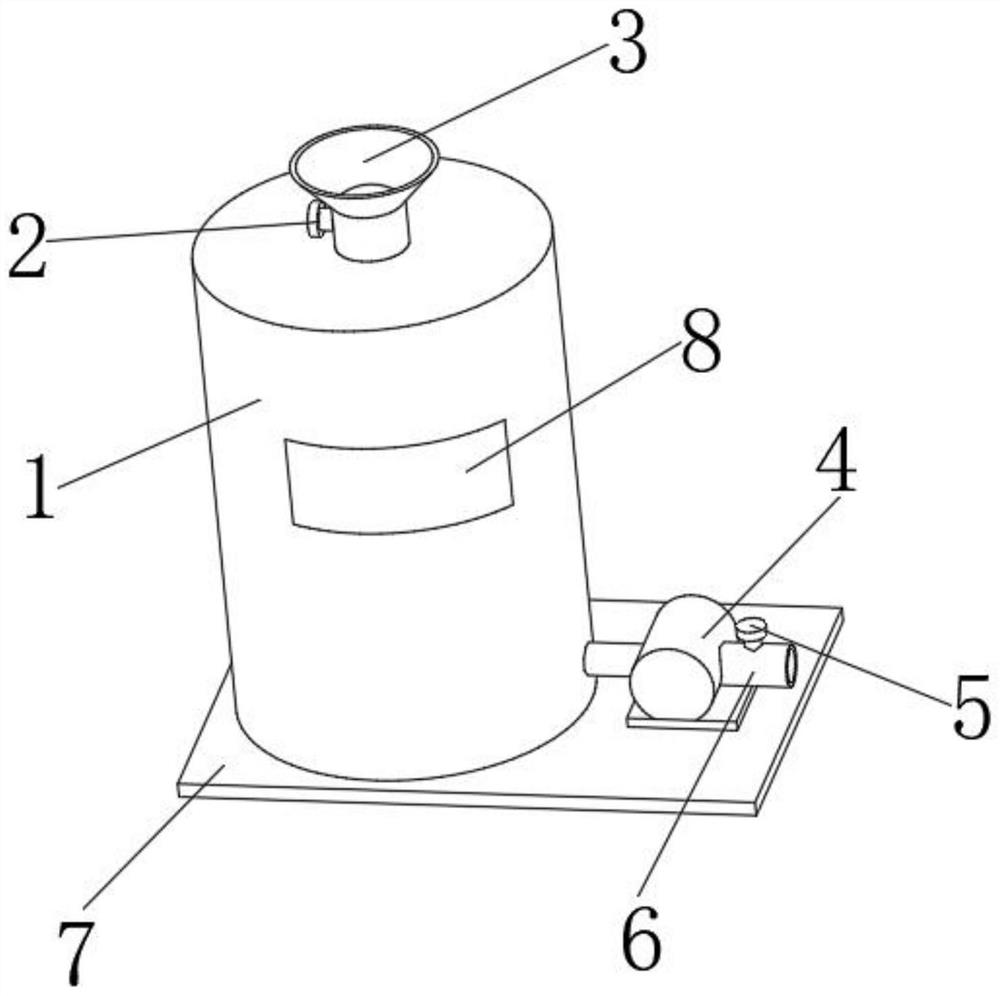

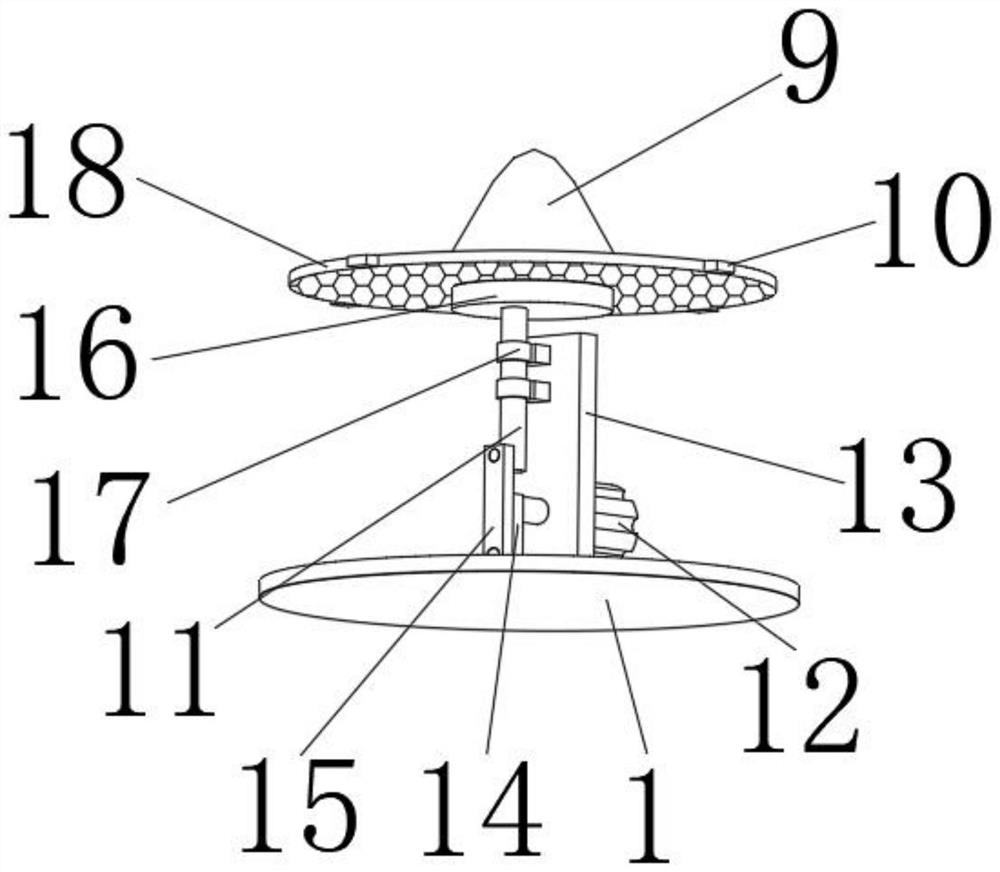

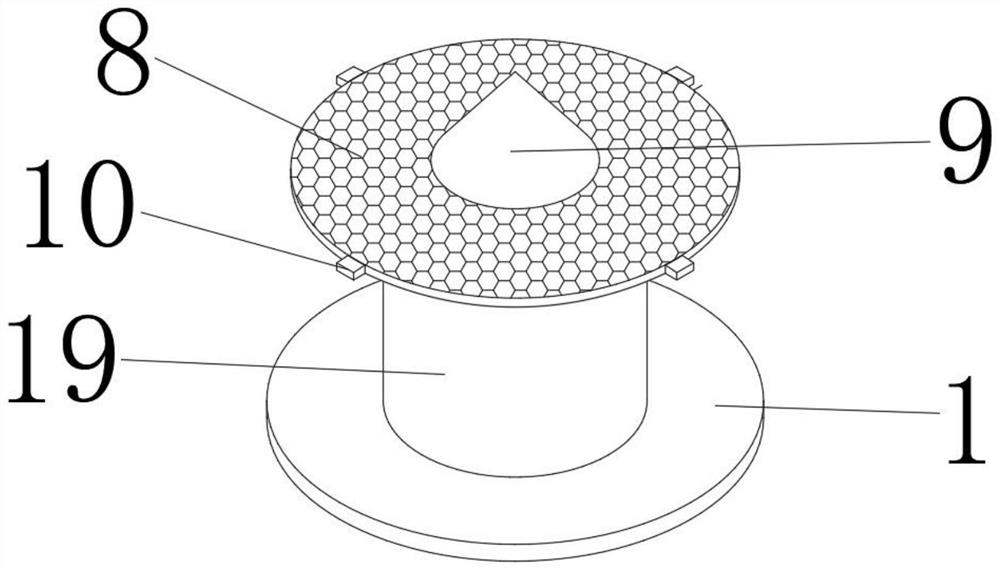

[0025] refer to Figure 1-3 , a nitrile rubber material manufacturing filter device, comprising a filter barrel 1, the bottom inner wall of the filter barrel 1 is connected with a mounting plate 13 by bolts, and one side outer wall of the mounting plate 13 is connected with a rotating motor 12 by bolts, and the rotating motor 12 The output shaft is connected with a rotating rod 14 through bolts, and one end of the rotating rod 14 is connected with a connecting rod 15 through a rotating shaft, one end of the connecting rod 15 is connected with a piston rod 11 through a rotating shaft, and the top outer wall of the piston rod 11 is connected with a support plate through bolts 16. Two limit rings 17 are connected to one side outer wall of the mounting plate 13 by bolts, and the piston rod 11 passes through the limit rings 17.

[0026] Wherein, the inner circumferential wall of the filter barrel 1 is equidistantly opened with limiting grooves, and the inner walls of the limiting g...

Embodiment 2

[0034] refer to Figure 4 , a filter device made of nitrile rubber material, compared with Example 1, one end of the discharge pipe 6 is connected with a hose 20 through a bolt.

[0035] When in use, use the soft 20 tube to control the position of the discharging material, so as to facilitate the adjustment of the cutting angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com