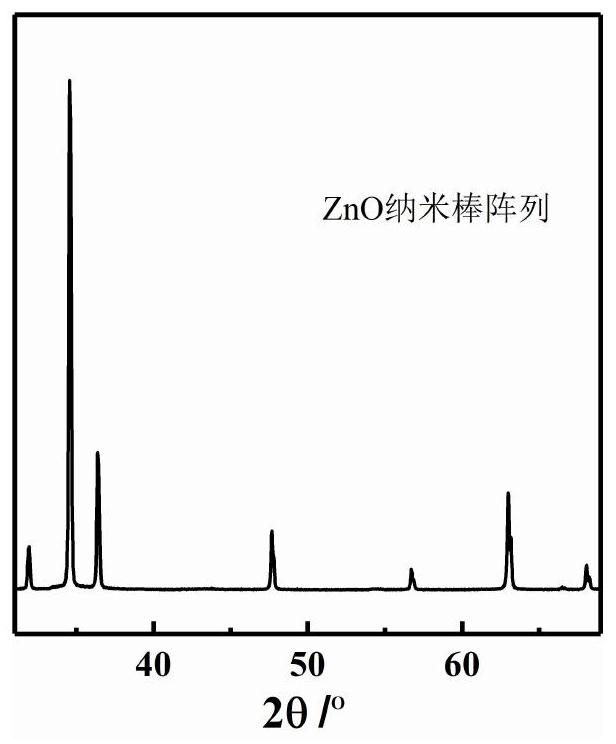

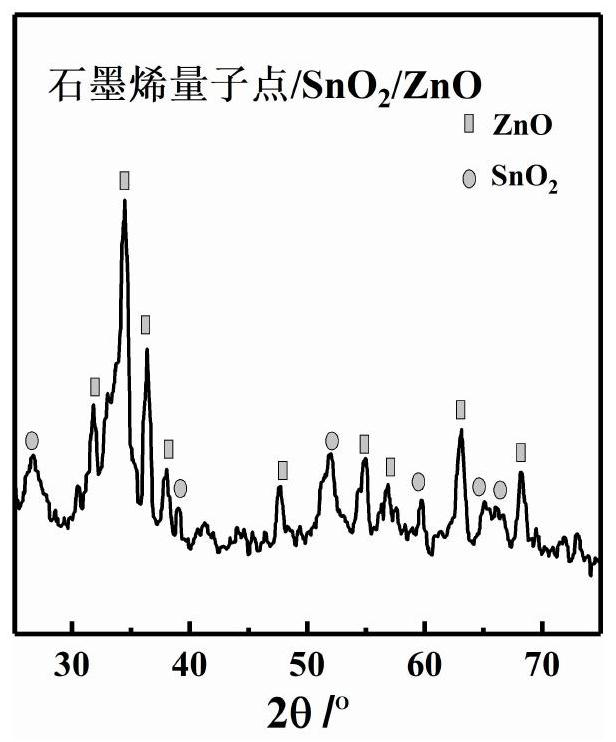

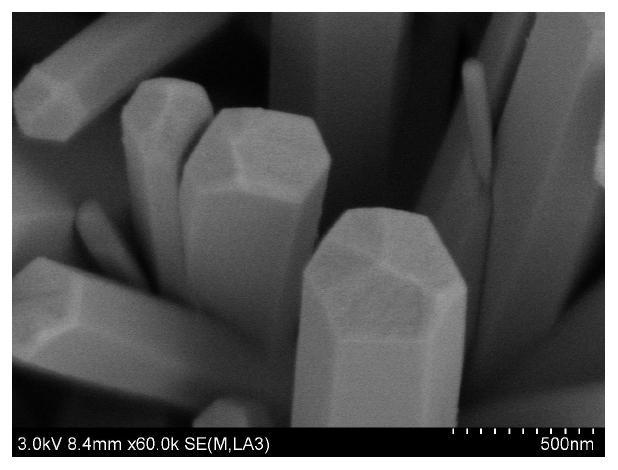

Composite nano-film material based on graphene quantum dot functionalization and gas sensitive sensing element

A technology of graphene quantum dots and nano-film materials, which is applied in the direction of analysis materials, material resistance, metal material coating technology, etc., can solve problems such as unfavorable high-performance sensing materials, and achieve improved sensitivity, low detection limit, and fast response /recovery time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present invention is based on graphene quantum dot functionalized tin oxide / zinc oxide H 2 The steps of the S sensor and its preparation method are as follows:

[0041] 1. First, use a plasma cleaning machine to clean the gas sensor device (the preparation process of gas sensor device loaded graphene refers to the literature (New Journal of Chemistry, 38(2014), 2362-2367), start the vacuum pump, and after vacuuming , Open the oxygen and argon gas circuit valves, feed oxygen and argon into the cleaning machine, control the pressure in the cleaning machine to 60Pa, start the cleaning machine, and the cleaning time is 5mins-10mins.

[0042] 2. Place the cleaned gas sensor element in the vacuum chamber of the magnetron sputtering equipment, use metal zinc with a mass purity of 99.99% as the target material, and use argon gas with a mass purity of 99.99% as the working gas. Sputter deposition of metal zinc film on the cleaned gas sensor element;

[0043] 3. In the proc...

Embodiment 2

[0060] The present invention is based on graphene quantum dot functionalized tin oxide / zinc oxide H 2 The steps of the S sensor and its preparation method are as follows:

[0061] 1. First, use a plasma cleaning machine to clean the gas sensor device (the preparation process of gas sensor device loaded graphene refers to the literature (New Journal of Chemistry, 38(2014), 2362-2367), start the vacuum pump, and after vacuuming , Open the gas path valves of oxygen and argon, feed oxygen and argon into the cleaning machine, control the pressure in the cleaning machine to 80Pa, start the cleaning machine, and the cleaning time is 5mins-10mins.

[0062] 2. Place the cleaned gas sensor element in the vacuum chamber of the magnetron sputtering equipment, use metal zinc with a mass purity of 99.99% as the target material, and use argon gas with a mass purity of 99.99% as the working gas. Sputter deposition of metal zinc film on the cleaned gas sensor element;

[0063] 3. In the proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com