A stereotactic polylactic acid/polytrimethylene carbonate biomass composite fiber

A methyl carbonate and composite fiber technology, applied in the direction of fiber chemical characteristics, conjugated synthetic polymer artificial filament, textiles and papermaking, can solve the problems of poor toughness, poor heat resistance and toughness of PLA fiber, and achieve Excellent hydrolysis resistance, excellent heat resistance, and excellent biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Dry sc-PLA and PTMC with a weight average molecular weight of 300,000;

[0036] Get each 50g of dried sc-PLA and PTMC, inject sc-PLA and PTMC into twin-screw extruder and melt blend, extrude granulation to obtain sc-PLA / PTMC blend;

[0037] Among them: the blending temperature is 240°C, and the blending time is 10 minutes;

[0038] (2) The sc-PLA / PTMC mixture was injected into the extruder to melt and extrude, and the as-spun fibers were collected. The temperature of the screw zone was 250°C, the temperature of the spinneret was 240°C, and the spinning speed was 600m / min;

[0039] (3) Draw the as-spun fiber 5 times at 120°C;

[0040] (4) Heat-treat the stretched sc-PLA / PTMC fiber at 190°C for 40 min under a tension of 0.3 cN / dtex to obtain the sc-PLA / PTMC biomass composite fiber;

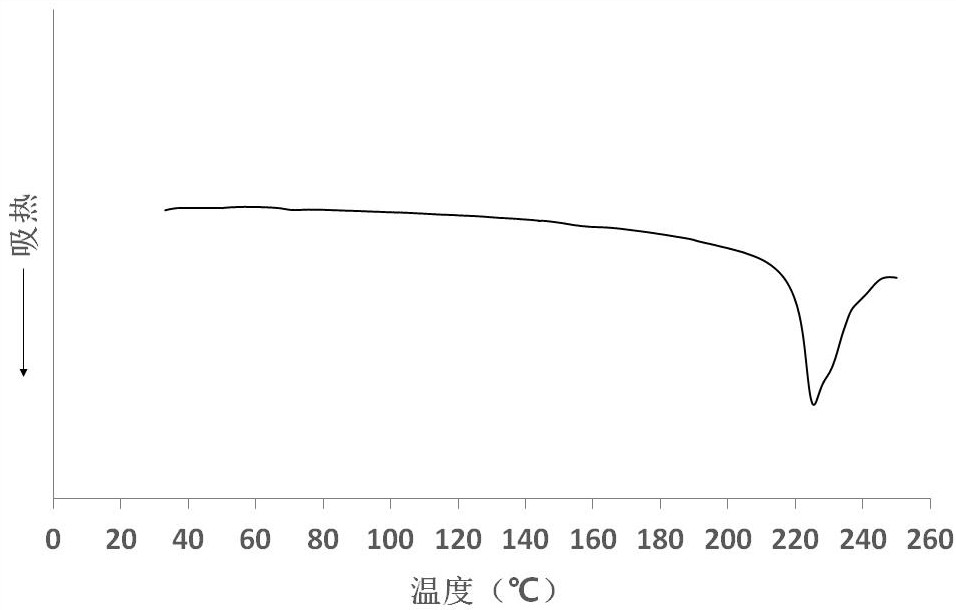

[0041] The fiber only has a melting peak around 222°C as measured by a differential scanning calorimeter, see figure 1 .

[0042] The melting point of the sc-PLA / PTMC biomass composit...

Embodiment 2

[0044] (1) Dry sc-PLA and PTMC with a weight average molecular weight of 300,000;

[0045] Get dried sc-PLA 80g and PTMC 20g, inject sc-PLA and PTMC into twin-screw extruder and melt blend, extrude granulation to obtain sc-PLA / PTMC blend;

[0046] Among them: the blending temperature is 250°C, and the blending time is 6 minutes;

[0047] (2) The sc-PLA / PTMC mixture is injected into the extruder to melt and extrude, and the as-spun fibers are collected. The temperature of the screw zone is 240°C, the temperature of the spinneret is 240°C, and the spinning speed is 800m / min;

[0048] (3) Draw the as-spun fiber 6 times at 140°C;

[0049] (4) Heat-treat the stretched sc-PLA / PTMC fiber at 200°C for 20 min under a tension of 0.3 cN / dtex to obtain the sc-PLA / PTMC biomass composite fiber;

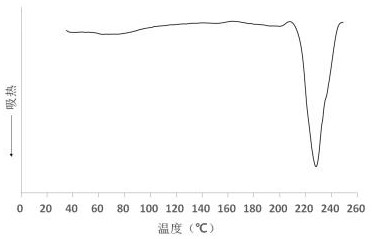

[0050] The fiber only has a melting peak around 227°C as measured by a differential scanning calorimeter, see figure 2 .

[0051] The melting point of the sc-PLA / PTMC biomass composite fiber i...

Embodiment 3

[0053](1) Dry sc-PLA and PTMC with a weight average molecular weight of 200,000;

[0054] Get dried sc-PLA 90g, PTMC 10g and tributyl citrate 5g, inject sc-PLA and PTMC into twin-screw extruder and melt blend, extrude granulation to obtain sc-PLA / PTMC blend;

[0055] Among them: the blending temperature is 250°C, and the blending time is 8 minutes;

[0056] (2) The sc-PLA / PTMC mixture is injected into the extruder to melt and extrude, and the as-spun fibers are collected. The temperature of the screw zone is 260°C, the temperature of the spinneret is 250°C, and the spinning speed is 1000m / min;

[0057] (3) Draw the nascent fiber 4 times at 130°C;

[0058] (4) Heat-treat the stretched sc-PLA / PTMC fiber at 205°C for 10 min under a tension of 0.3 cN / dtex to obtain the sc-PLA / PTMC biomass composite fiber;

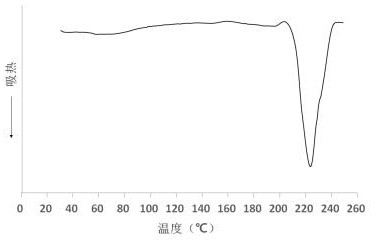

[0059] The fiber only appears a melting peak around 226°C as measured by a differential scanning calorimeter, see image 3 .

[0060] The melting point of the sc-PLA / PTMC b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com