Post-processing method of high-brightness copper ornament

A decoration and brightness technology, applied in the direction of metal material coating process, can solve problems such as high cost, damage to copper decorations, increase storage time, etc., to improve high and low temperature resistance, prolong corrosion resistance, and prevent damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

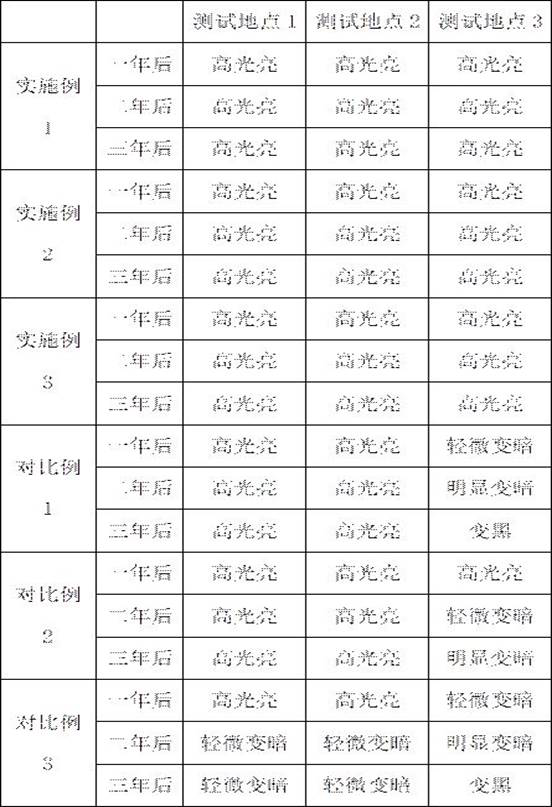

Examples

Embodiment 1

[0015] A post-processing method for high-brightness copper decorations, comprising the following steps:

[0016] A Clean the copper ornaments with deionized water, then put them into the passivation solution and soak for 55s to passivate the surface of the copper ornaments; then take out the copper ornaments and dry them with a dry cloth, pour them into Soak in glycerin for 12s, then quickly dry at 160°C;

[0017] B Wrap the surface of the copper ornament with cotton cloth, and then place it in a low temperature of minus 25°C for 50 hours;

[0018] C Take out the copper decoration wrapped in cotton cloth, then wash off the glycerin on the surface with deionized water and dry it with a dry cloth.

[0019] In the step A, the passivation solution is composed of the following components by weight percentage: phytic acid 0.5%, disodium edetate 1.8%, hydrogen peroxide 3.5%, boric acid 0.8%, polyethylene glycol 1.8% % and the balance of deionized water.

Embodiment 2

[0021] A post-processing method for high-brightness copper decorations, comprising the following steps:

[0022] A Clean the copper decorations with deionized water, then put them into the passivation solution and soak for 65s to passivate the surface of the copper decorations; then take out the copper decorations and dry them with a dry cloth, pour them into Soak in glycerin for 8s, then quickly dry at 180°C;

[0023] B Wrap the surface of the copper ornament with cotton cloth, and then leave it to stand for 48 hours at a low temperature of minus 30°C;

[0024] C Take out the copper decoration wrapped in cotton cloth, then wash off the glycerin on the surface with deionized water and dry it with a dry cloth.

[0025] In the step A, the passivation solution is composed of the following components by weight percentage: 0.8% phytic acid, 1.5% disodium edetate, 5% hydrogen peroxide, 0.5% boric acid, polyethylene glycol 3 % and the balance of deionized water.

Embodiment 3

[0027] A post-processing method for high-brightness copper decorations, comprising the following steps:

[0028] A Clean the copper decorations with deionized water, then put them into the passivation solution and soak for 45s to passivate the surface of the copper decorations; then take out the copper decorations and dry them with a dry cloth, pour them into Soak in glycerin for 15s, then quickly dry at 150°C;

[0029] B Wrap the surface of the copper ornament with cotton cloth, and then place it in a low temperature of minus 22°C for 60 hours;

[0030] C Take out the copper decoration wrapped in cotton cloth, then wash off the glycerin on the surface with deionized water and dry it with a dry cloth.

[0031] In the step A, the passivation solution is composed of the following components by weight percentage: phytic acid 0.3%, disodium edetate 2.5%, hydrogen peroxide 2%, boric acid 1.2%, polyethylene glycol 1% % and the balance of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com