Amino curing agent, high-temperature-resistant epoxy resin containing curing agent and preparation method and application thereof

A technology of epoxy resin and epoxy resin matrix, which is applied in the direction of epoxy resin glue, epoxy resin coating, adhesive, etc., and can solve problems such as difficult to meet high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

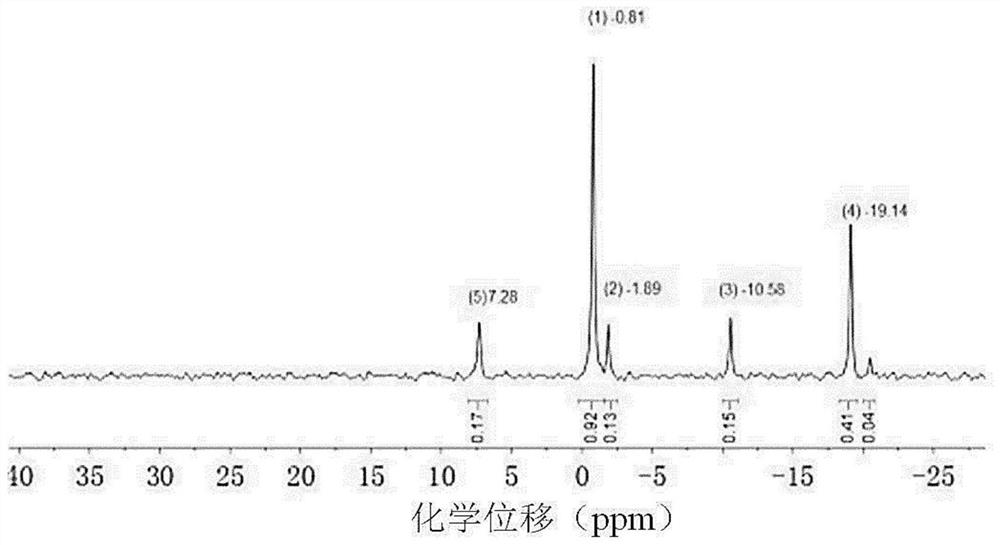

[0064] Preparation of amine-based curing agent containing m-carborane in structure A: Add 1 part of m-carborane to 2 parts of NaN under the protection of nitrogen flow 3 in toluene, stirred at 110°C and refluxed for 4h, filtered to remove excess NaN 3 And wash the filtrate with distilled water. Under the protection of nitrogen flow, the mixture was stirred and heated at 60°C for 2 hours. The reaction mixture was poured into ice water, the pH value of the mixture was adjusted to neutral with lye and extracted with ether, and anhydrous MgSO was added. 4 After removing the distilled water, the amine-based curing agent containing meta-carborane with the structure shown in formula (A): diamine-based meta-carborane can be obtained.

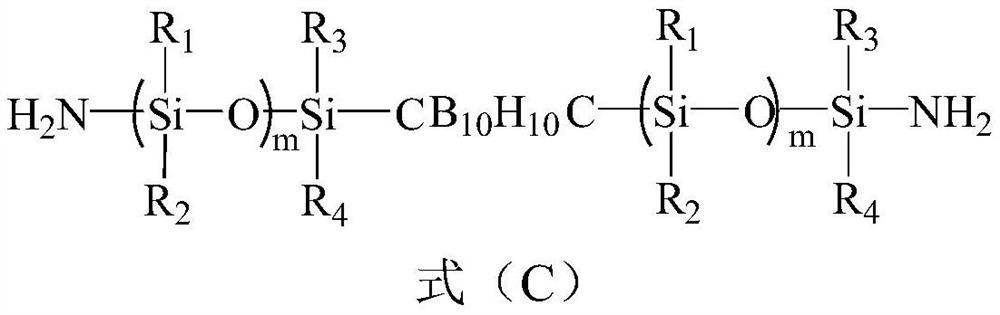

[0065] The preparation of the amine-based curing agent containing m-carborane in B structure: (1) the m-carborane of 1 part of substance is dissolved in the dry ethylene glycol dimethyl ether of 10 parts by volume, in an ice-water bath Under the prote...

Embodiment 1

[0068] Use novolac epoxy resin F51 as the epoxy resin matrix, use A-structure diamino-meta-carborane as the curing agent, and mix according to the mass ratio of F51 and A-structure diamino-meta-carborane as 100:20 , after curing at 180°C for 2 hours, a high temperature resistant cured epoxy resin was obtained.

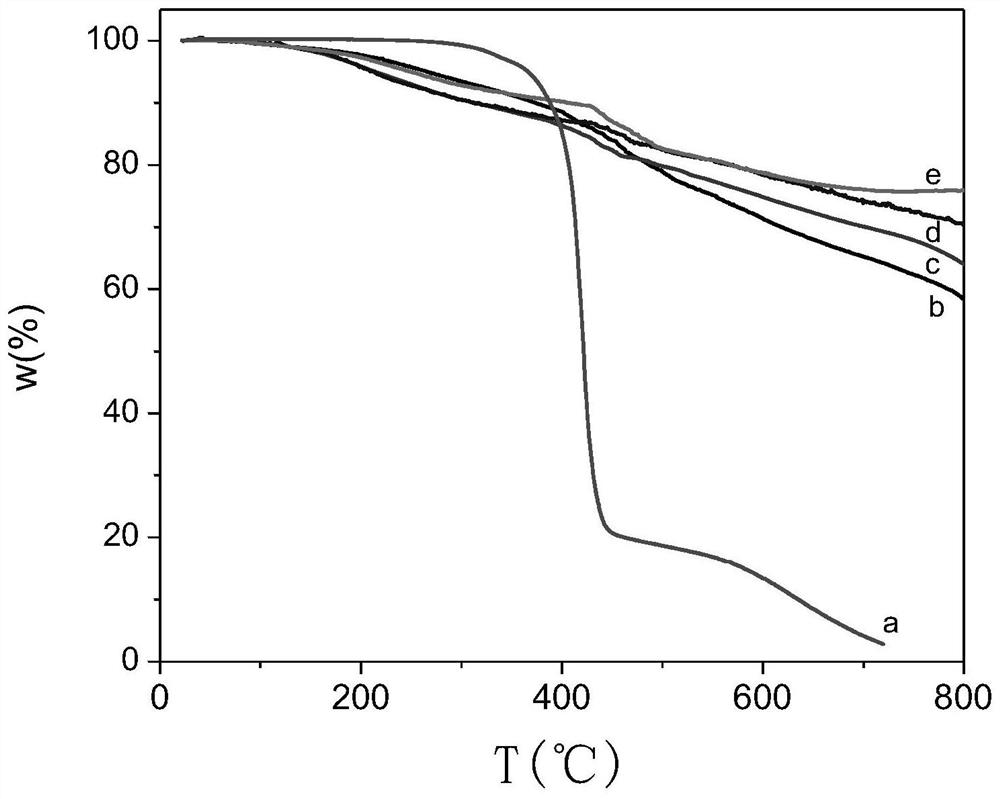

[0069] Test the thermal weight loss of the cured product in an air atmosphere: the mass retention rate at 800 ° C is 76% ( figure 1 Curve e) in .

[0070] According to the bonding strength test, the bonding strength of the cured epoxy resin is 14.5MPa at room temperature, and 2.8MPa after aging in air at 600°C for 1 hour.

Embodiment 2

[0072] Take the novolac epoxy resin F44 as the epoxy resin matrix, take the bis (m-aminophenyl) m-carborane in the B structure as the curing agent, according to the quality of F44 and bis (m-aminophenyl) m-carborane The mixture was mixed at a ratio of 100:50, and cured at 160°C for 4 hours to obtain a high temperature resistant epoxy resin cured product.

[0073] Test the thermal weight loss of the cured product in an air atmosphere: the mass retention rate at 800 ° C is 71% ( figure 1 Curve d) in .

[0074] According to the bonding strength test, the bonding strength of the cured epoxy resin is 15.8 MPa at room temperature, and 2.6 MPa after aging in air at 600°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com