Preparation method of high-flow-state super-early-strength gravity mortar for sound barrier

An ultra-early strength, sound barrier technology, applied in the field of building materials, can solve the problems of slow development of construction strength, slow plastic loss, slow strength development, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

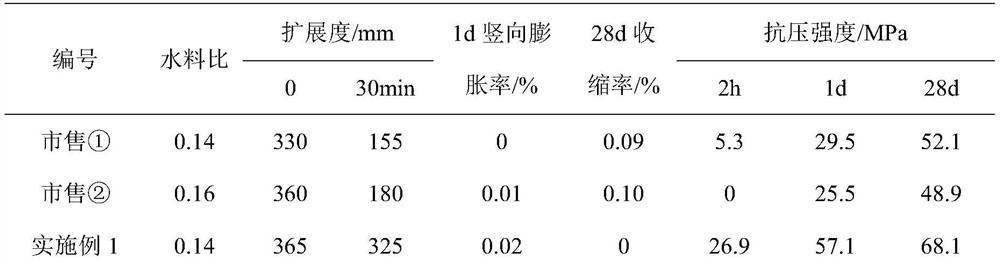

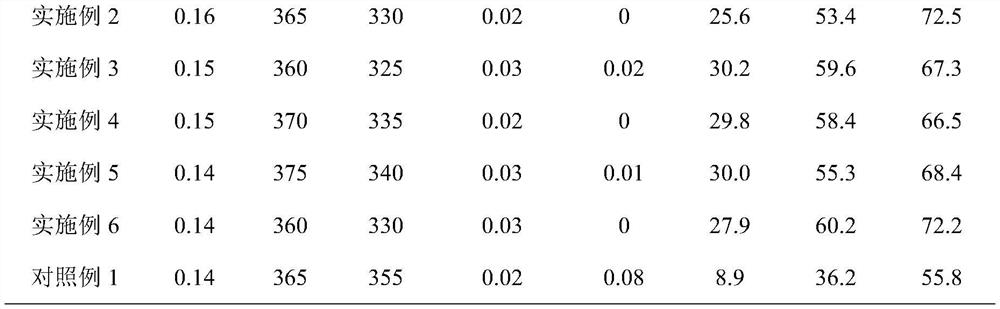

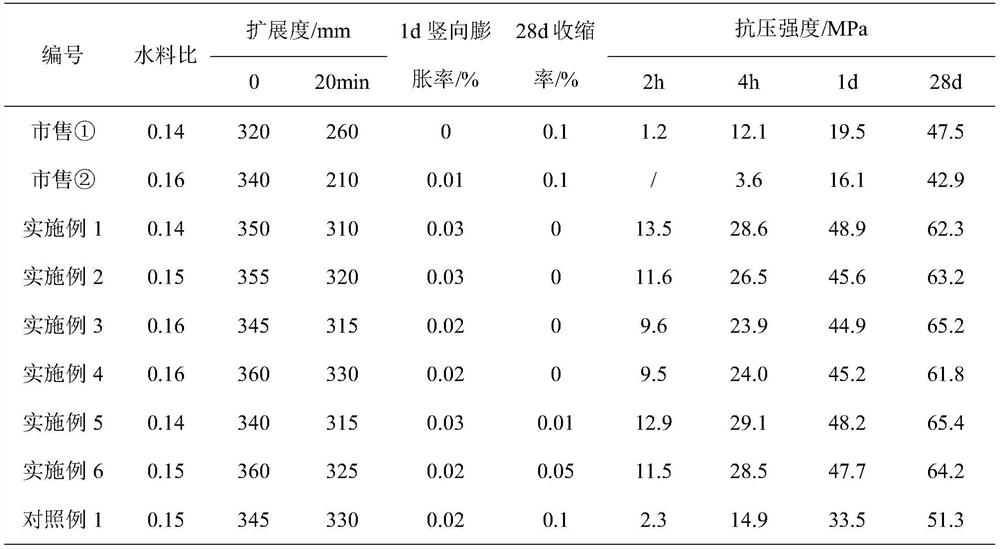

Examples

Embodiment 1

[0027] 1) Preparation of high-strength nucleating agent: Dissolve 1g of vinyl acetate and ethylene copolymer rubber powder, 0.5g of SD-600P-F polycarboxylate superplasticizer and 5.0g of triisopropanolamine in deionized water at 30°C and stir for 30min. Then, 10 g of 30% concentration of sodium silicate nonahydrate and 15 g of 30% concentration of calcium acetate monohydrate were added for reaction, and the reaction time was 120 minutes. Dry the solution prepared by the reaction at 105°C to obtain a powder-type high-strength nucleating agent with a pH of 12;

[0028] 2) Preparation method of gravity mortar for high-fluid super-early-strength sound barrier: by mass percentage, R·FAC 525 fast-hardening iron-aluminate cement: 30.0%, P·II 525 Portland cement: 20.0%, 0.5mm ~2mm Quartz sand with continuous collection: 38.0%, specific surface area 2500m 2 / kg beads: 10.0%, step 1) high-strength nucleating agent: 1.1%, SD-600P-F polycarboxylate superplasticizer: 0.365%, sodium citrat...

Embodiment 2

[0030]1) Preparation of high-strength nucleating agent: Dissolve 1g of vinyl acetate homopolymer rubber powder, 0.3g of SD-600P-F polycarboxylate superplasticizer and 2.0 of diethanolamine in deionized water at 50°C and stir for 45min, then add mass concentration 30g of 15% sodium silicate nonahydrate and 35g of 15% calcium acetate monohydrate were reacted, and the reaction time was 100min. Dry the solution prepared by the reaction at 110°C to obtain a powder-type high-strength nucleating agent with a pH of 10;

[0031] 2) Preparation method of gravity mortar for high-fluid super-early-strength sound barrier: by mass percentage, R·FAC 525 fast-hardening iron-aluminate cement: 50.0%, P·II 525 Portland cement: 10.0%, 0.5mm ~2mm quartz sand with continuous collection: 35.0%, specific surface area is 2800m 2 / kg beads: 3.0%, step 1) high-strength nucleating agent: 0.95%, SD-600P-F polycarboxylate superplasticizer: 0.50%, citric acid: 0.50%, ML-861-6 powder for concrete Antifoami...

Embodiment 3

[0033] 1) Preparation of high-strength nucleating agent: Dissolve 1g of acrylate and styrene copolymer rubber powder, 0.5g of SD-600P-F polycarboxylate superplasticizer and 4.5g of triethanolamine in deionized water at 45°C and stir for 60min, then add mass 25g of 18% sodium silicate nonahydrate and 25g of 23% calcium acetate monohydrate were reacted, and the reaction time was 180min. Dry the solution prepared by the reaction at 108°C to obtain a powder-type high-strength nucleating agent with a pH of 14;

[0034] 2) Preparation method of gravity mortar for high-fluid super-early-strength sound barrier: by mass percentage, R·FAC 525 fast-hardening iron-aluminate cement: 30.0%, P·II 525 Portland cement: 10.0%, 0.5mm ~2mm quartz sand with continuous collection: 55.0%, specific surface area is 3000m 2 / kg beads: 3.0%, step 1) high-strength nucleating agent: 1.37%, SD-600P-F polycarboxylate superplasticizer: 0.35%, white sugar: 0.25%, ML-861-6 powder for concrete Antifoaming age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com